Vitrified bond cubic boron nitride (CBN) grinding wheel for grinding titanium alloy

A ceramic bond and cubic boron nitride technology, applied in the field of grinding tools, can solve the problems of poor grinding performance of titanium alloys, easy formation of hard and brittle surface layers on the surface, difficult control of grinding quality, etc., and achieve grinding costs. Low, high grinding efficiency, good self-sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

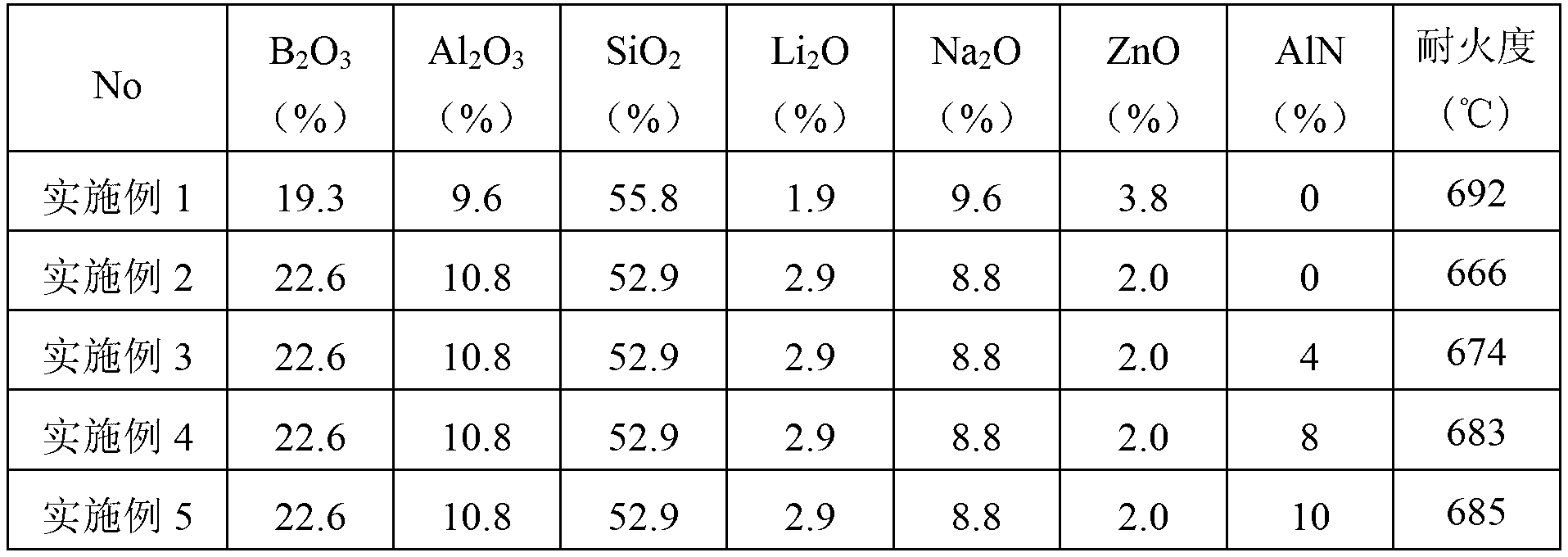

[0018] The present invention will be further described below in combination with specific implementation cases.

[0019] The present invention adopts conventional chemical raw materials and conventional preparation methods, and first prepares vitrified bonding agent.

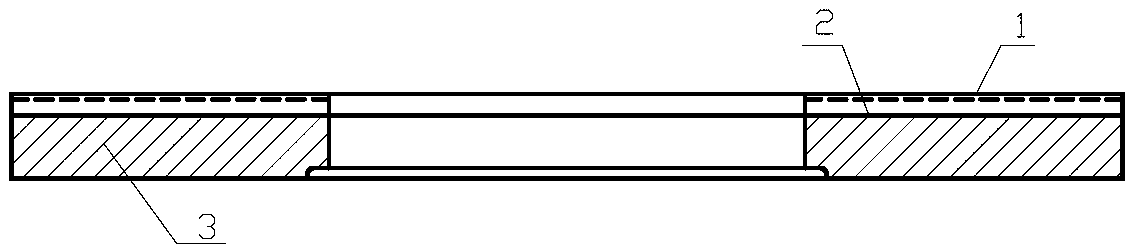

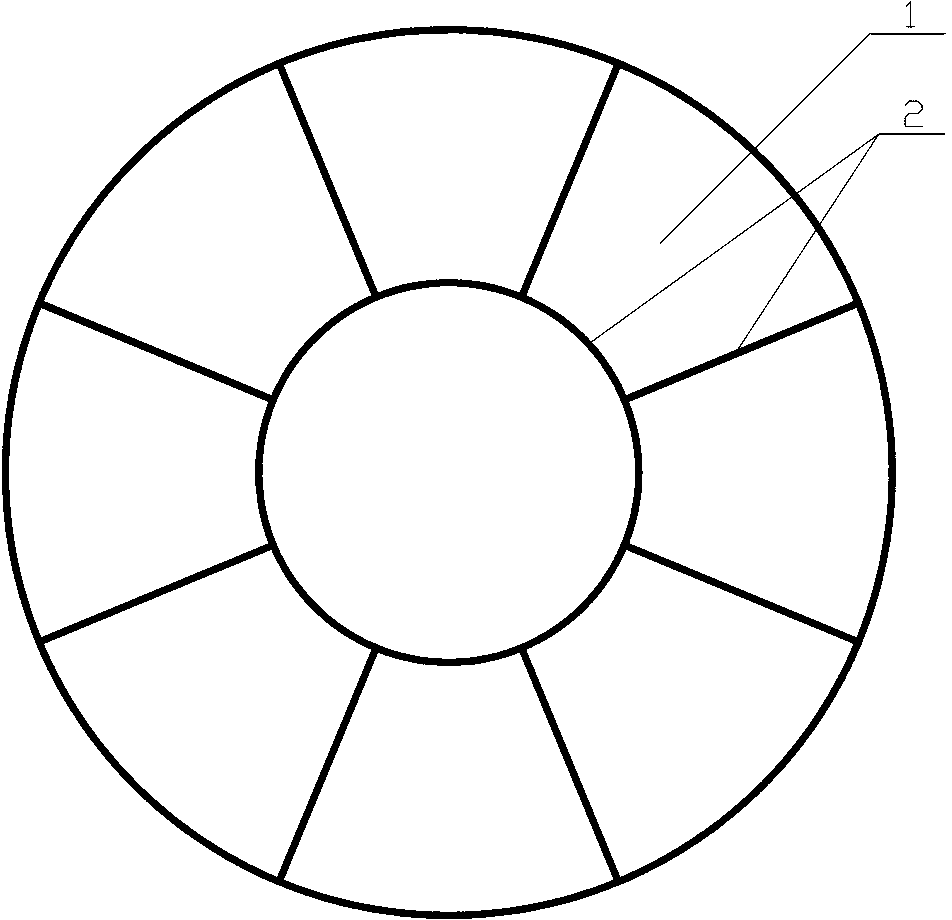

[0020] Compared with ordinary silicon carbide and corundum abrasives, cubic boron nitride abrasives can be oxidized at lower temperatures (below 1000°C), and will be transformed into graphite-like hexagonal structures above 1200°C, losing their superhardness. Due to the characteristics of the abrasive, the vitrified cubic boron nitride grinding wheel needs to be sintered at a low temperature compared with the ordinary vitrified bonded grinding wheel, that is, the refractoriness of the vitrified bond itself is lower. In addition, due to the large amount of grinding heat generated during the grinding process, and 60-95% of the heat is transmitted to the workpiece, and the thermal conductivity of the titanium alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com