Gear tooth surface grinding mechanism

A grinding mechanism and gear technology, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of increasing grinding costs, small gaps between teeth, and affecting grinding quality, so as to improve grinding efficiency , reduce manual operation, improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below.

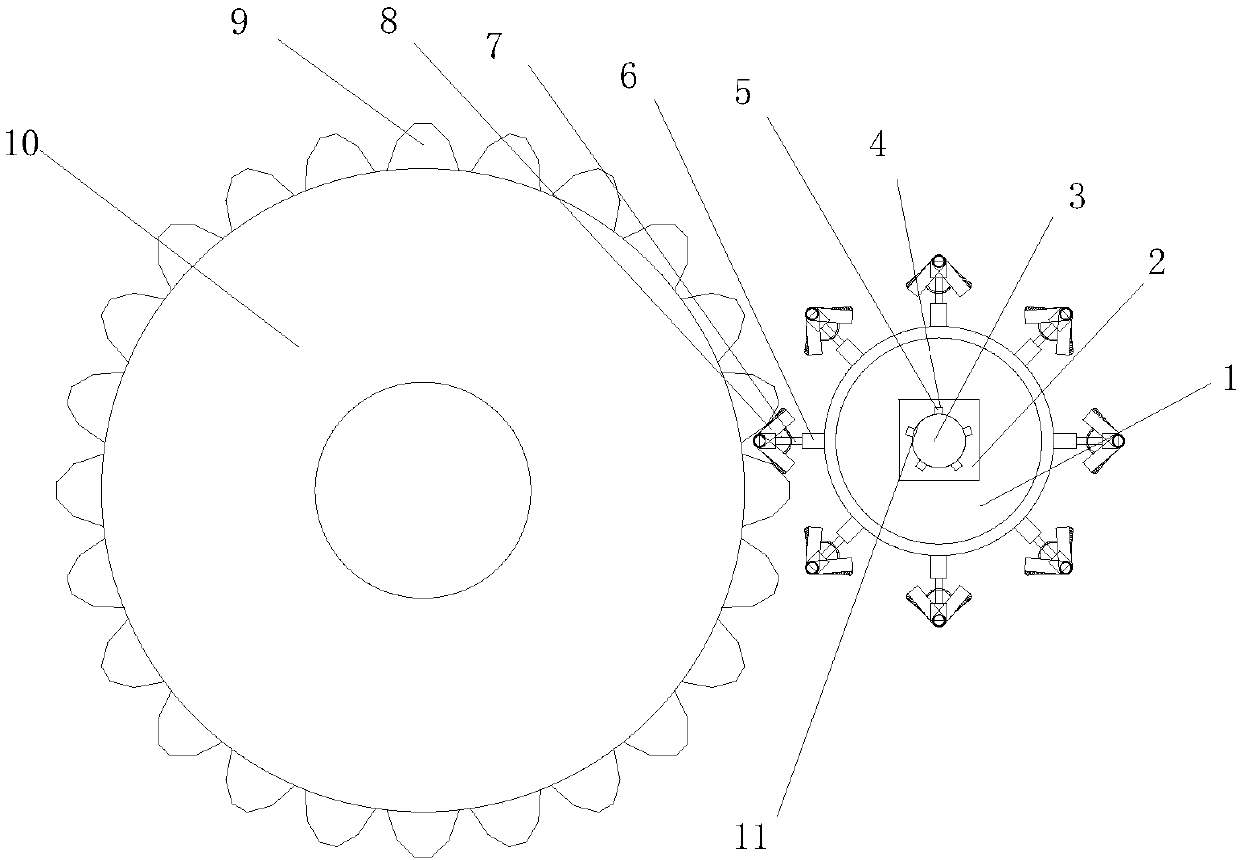

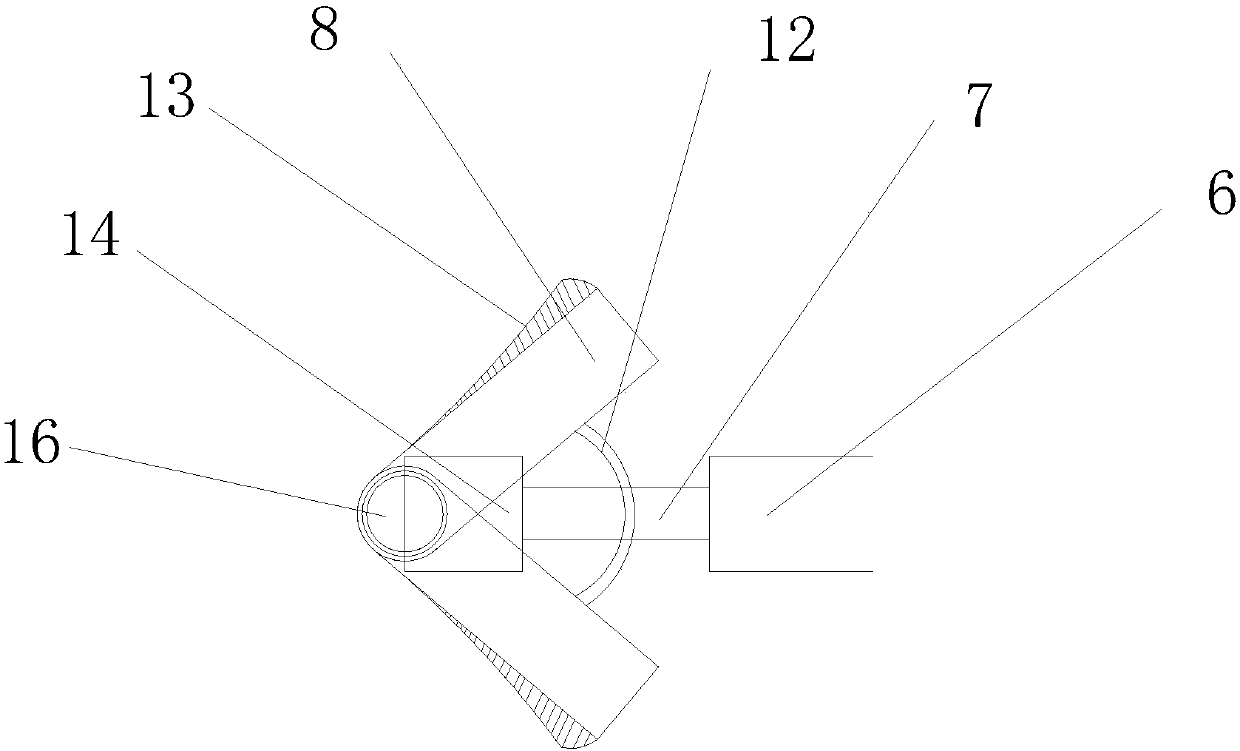

[0022] Please refer to figure 1 , figure 2 , a tooth surface grinding mechanism for a gear, comprising a gear 10, the gear 10 is provided with uniform teeth 9, and one side of the gear 10 is provided with a grinding device for fine grinding of the surface of the teeth 9 , the grinding device includes a grinding head and a rotating disc 1, the grinding heads are divided into multiple groups and evenly arranged on a circle of the rotating disc 1, and the connecting block 14 of the grinding head is connected with the drive motor 6 through the rotating rod 7 , the grinding head is in contact with the side of the tooth 9, and the connecting hole 11 at the center of the rotating disk 1 is connected with the connecting rod 3 of the screw-in motor 2.

[0023] Further, the grinding head is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com