Polishing equipment and method

A technology of equipment and grinding tools, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problem of low grinding efficiency and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

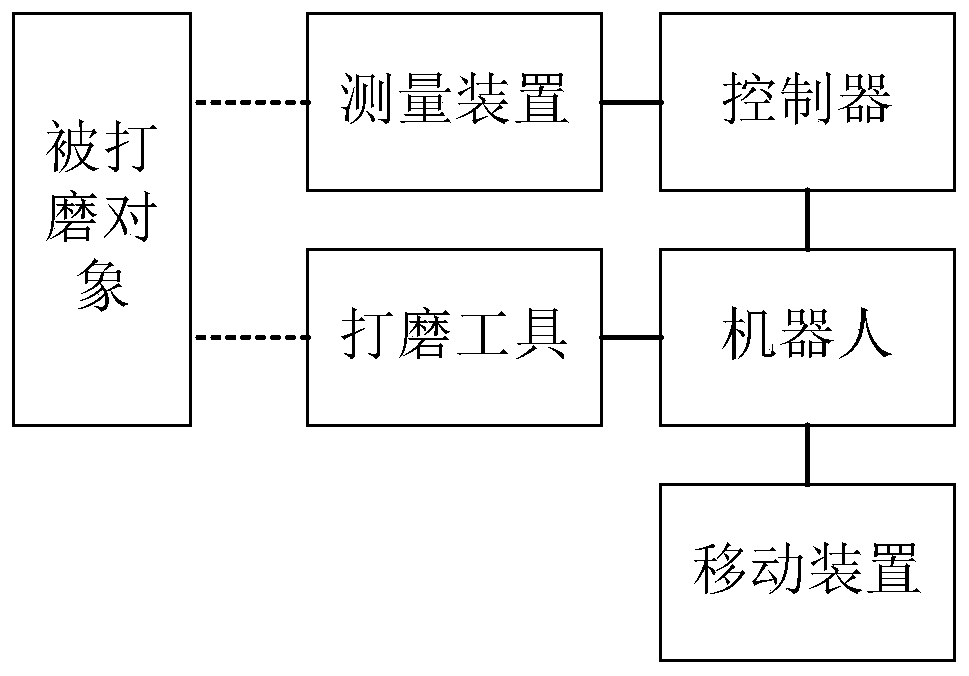

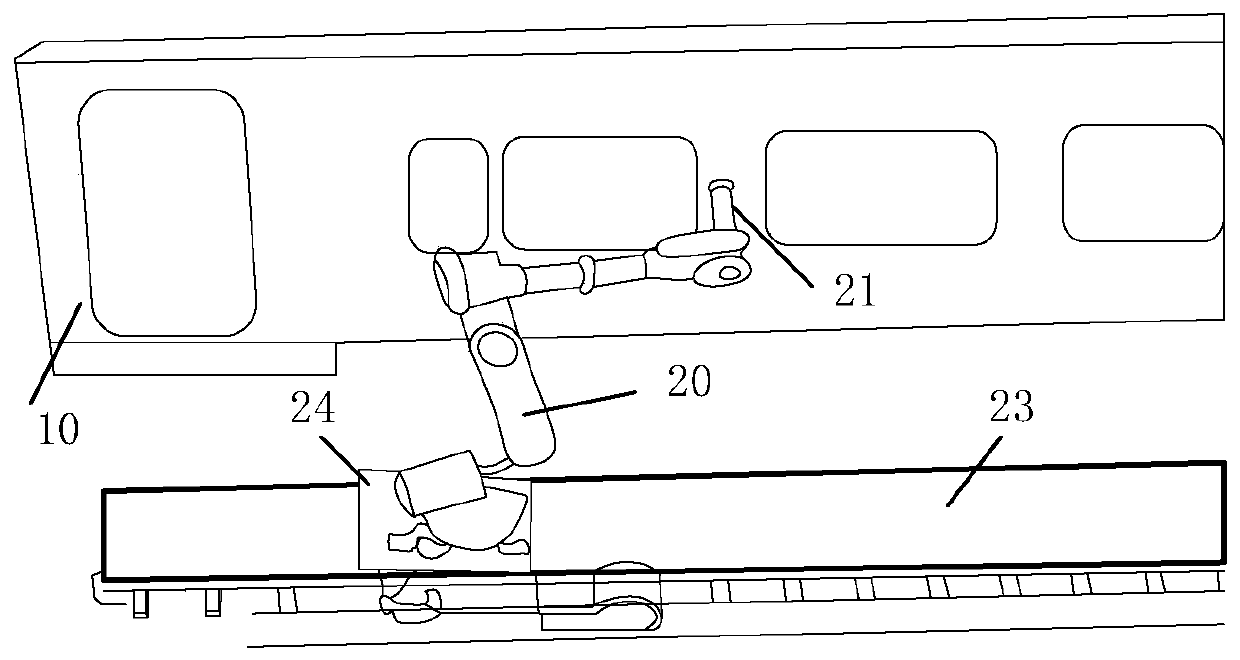

[0035] According to an embodiment of the present invention, an embodiment of a grinding device is provided. It should be noted that the grinding device provided in this embodiment can be applied in the grinding of high-speed rail car bodies, and can also be applied in other fields that require equipment grinding. in, figure 1 is a schematic diagram of a polishing device according to an embodiment of the present invention, such as figure 1 As shown, the grinding equipment includes: a measuring device, a robot and a controller.

[0036] Among them, the measuring device is used to collect the data of the polished object.

[0037] Optionally, the measurement device may be an optical measurement system, wherein the optical measurement system may include at least one of the following: an optical detector, an X-ray detector, a laser side thickness meter, a gloss detector, a light transmittance tester, a color difference Instruments, infrared scanners, thermometers, etc.

[0038] I...

Embodiment 2

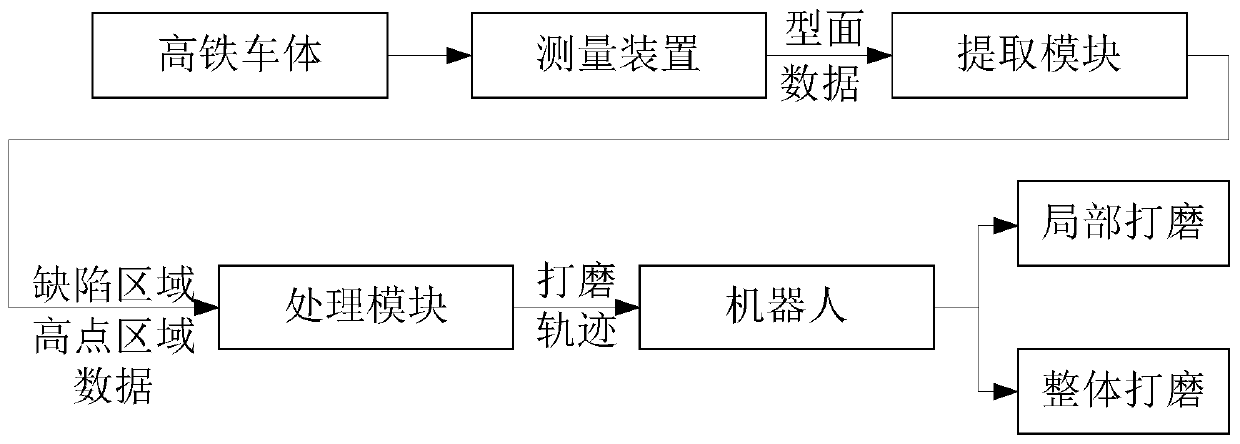

[0062] According to an embodiment of the present invention, an embodiment of a grinding method is also provided. It should be noted that the controller in Embodiment 1 can be used as the execution subject of this embodiment. In addition, the steps shown in the flow diagrams of the figures may be performed in a computer system, such as a set of computer-executable instructions, and, although a logical order is shown in the flow diagrams, in some cases, the sequence may be different. The steps shown or described are performed in the order herein.

[0063] Figure 7 is a flow chart of a grinding method according to an embodiment of the present invention, as Figure 7 As shown, the method includes the following steps:

[0064] Step S702, receiving the collected data of the polished object.

[0065] In this embodiment, the object to be polished can be a high-speed rail car body, and the data of the object to be polished is the data collected by various instruments in the optical...

Embodiment 3

[0089] According to another aspect of the embodiments of the present invention, a processor is also provided, and the processor is used to run a program, wherein the polishing method in the above-mentioned embodiment 2 is executed when the program is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com