Textile fabric sanding machine capable of sequentially sanding and automatically cleaning

A technology for automatic cleaning and weaving of fabrics, applied in textiles and papermaking, cleaning methods using gas flow, fabric surface trimming, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

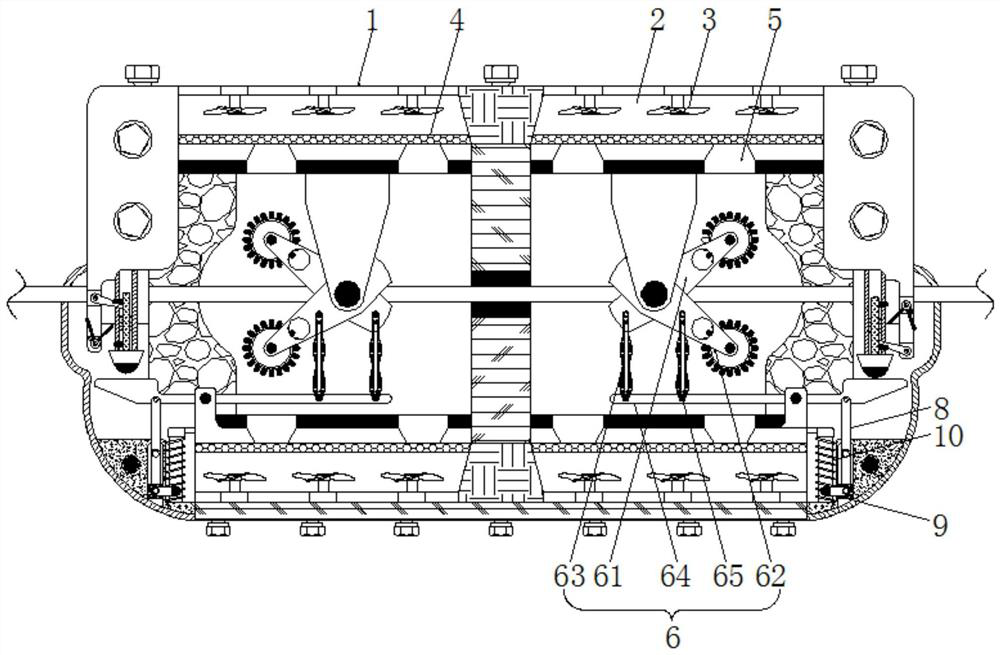

[0024] see figure 2 , a textile cloth sanding machine for sequentially sanding and automatic cleaning, comprising a casing 1, a negative pressure chamber 2 is opened inside the casing 1, a negative pressure fan 3 is connected to the interior of the negative pressure chamber 2, and the negative pressure fan 3 is set The number of negative pressure fans 3 is not less than three, and the specifications of each negative pressure fan 3 are the same, and they are evenly distributed in the interior of the negative pressure chamber 2. The rotation of the negative pressure fan 3 is used to generate negative pressure for cleaning. The interior of the negative pressure chamber 2 is clamped with The filter screen 4, the inside of the negative pressure chamber 2 are provided with a cleaning port 5, and the inside of the housing 1 is movably connected with a cleaning mechanism 6, the cleaning mechanism 6 includes an upper cleaning plate 61, and the surface of the upper cleaning plate 61 is ...

Embodiment 2

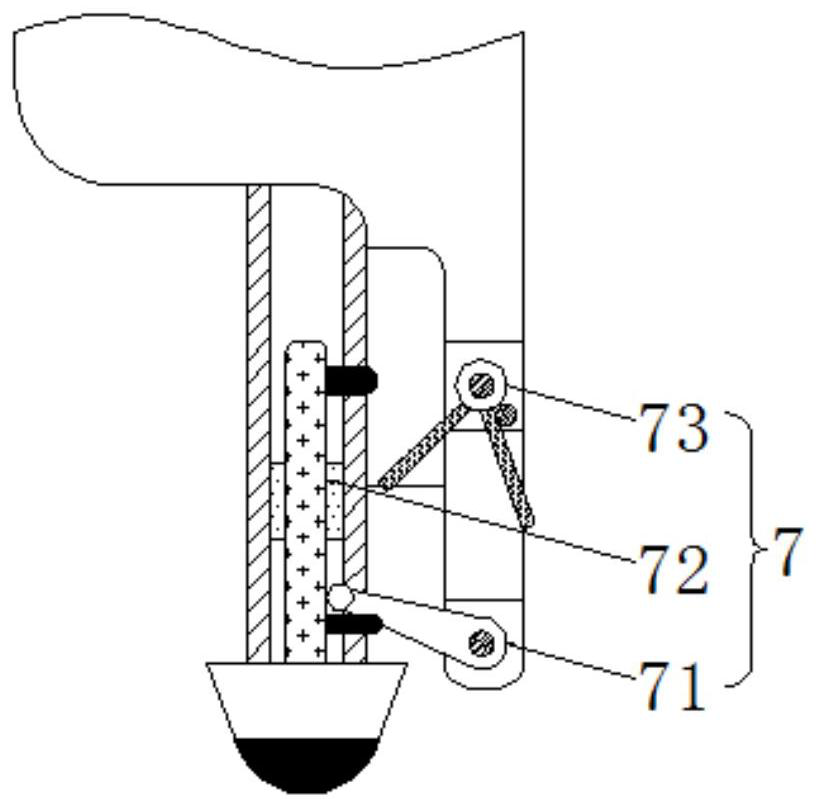

[0026] see figure 2 , a textile cloth sanding machine for sequentially sanding and automatic cleaning, comprising a casing 1, a negative pressure chamber 2 is opened inside the casing 1, a negative pressure fan 3 is connected to the interior of the negative pressure chamber 2, and the negative pressure fan 3 is set The number of negative pressure fans 3 is not less than three, and the specifications of each negative pressure fan 3 are the same, and they are evenly distributed in the interior of the negative pressure chamber 2. The rotation of the negative pressure fan 3 is used to generate negative pressure for cleaning. The interior of the negative pressure chamber 2 is clamped with The filter screen 4, the inside of the negative pressure chamber 2 are provided with a cleaning port 5, and the inside of the shell 1 is movably connected with a cleaning mechanism 6, and the side end of the cleaning mechanism 6 is movably connected with a limit mechanism 7, and the limit mechanis...

Embodiment 3

[0028] see Figure 1-3 , a textile cloth sanding machine for sequentially sanding and automatic cleaning, comprising a casing 1, a negative pressure chamber 2 is opened inside the casing 1, a negative pressure fan 3 is connected to the interior of the negative pressure chamber 2, and the negative pressure fan 3 is set The number of negative pressure fans 3 is not less than three, and the specifications of each negative pressure fan 3 are the same, and they are evenly distributed in the interior of the negative pressure chamber 2. The rotation of the negative pressure fan 3 is used to generate negative pressure for cleaning. The interior of the negative pressure chamber 2 is clamped with The filter screen 4, the inside of the negative pressure chamber 2 are provided with a cleaning port 5, and the inside of the housing 1 is movably connected with a cleaning mechanism 6, the cleaning mechanism 6 includes an upper cleaning plate 61, and the surface of the upper cleaning plate 61 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com