Machining method for inner ring and outer ring of conical roller bearing

A technology of tapered roller bearings and processing methods, which is applied in the field of bearing processing, can solve the problems of reducing grinding processing efficiency, increasing manufacturing costs, increasing grinding amount, etc., and achieves improving turning processing efficiency, saving turning processing time, and improving grinding processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

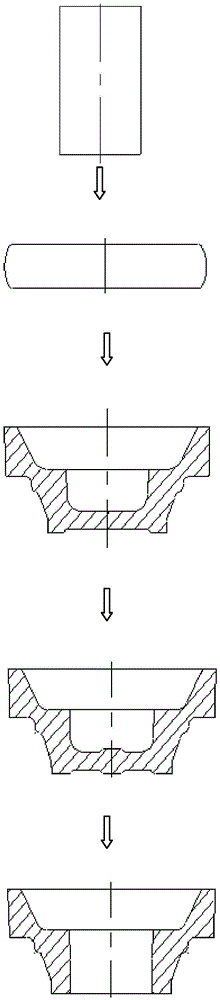

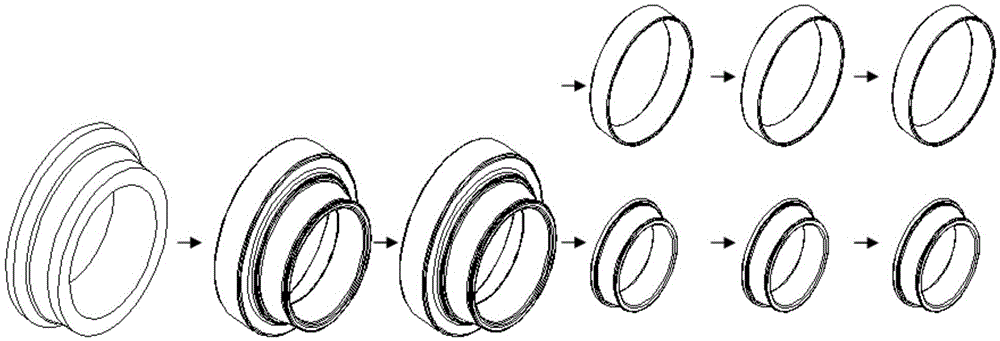

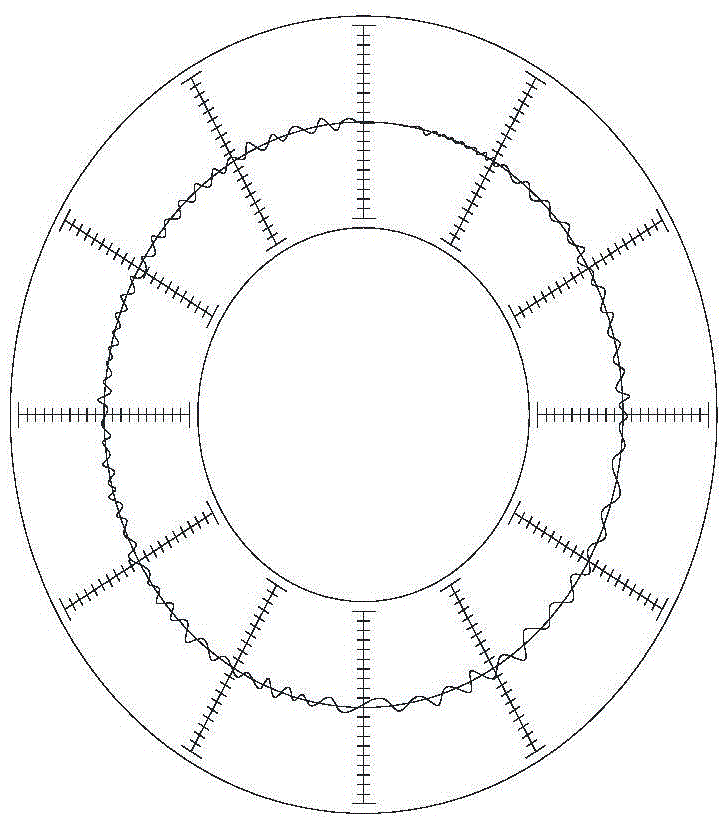

[0031] Specific implementation mode one: combine figure 2 Describe this embodiment, a method for processing the inner and outer rings of a tapered roller bearing in this embodiment, the method includes the following steps:

[0032] Step 1: Non-destructive testing of steel;

[0033] Steel bar non-destructive testing equipment sorts mixed steel, eddy current flaw detection for surface cracks, ultrasonic internal defect detection, automatically paints and marks the parts of steel bars that do not meet the testing requirements, and scraps the defective parts after they are cut off;

[0034] Step 2: cutting the detected steel;

[0035] Step 3: Forging inner and outer connecting ferrules;

[0036] A 2,500-ton hot forging machine and an automatic feeding device are used to automatically forge the inner and outer rings. The forging process is four stations: upsetting, preforming, forming, and punching. The forging time is 5S / piece and the forging temperature is: The initial forgin...

specific Embodiment approach 2

[0058] Specific implementation mode two: combination figure 2 To describe this embodiment, the end face after cutting in step 2 of this embodiment is measured with an angle ruler. Such setting is convenient to ensure the hardness requirements of the inner and outer rings. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0059] Specific implementation mode three: combination figure 2 To describe this embodiment, the carburizing temperature in Step 6 of this embodiment is 930°C. Such setting is convenient to ensure the hardness requirements of the inner and outer rings. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com