Method for performing fine sieving, regrinding and bulk flotation on low-level silicon calcium collophanite

A hybrid flotation and calcigrade technology, applied in flotation, solid separation, grain treatment, etc., can solve the problem of secondary sludge deteriorating the flotation process, etc., achieve good flotation effect, reduce grinding costs, float Select the effect of foam viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

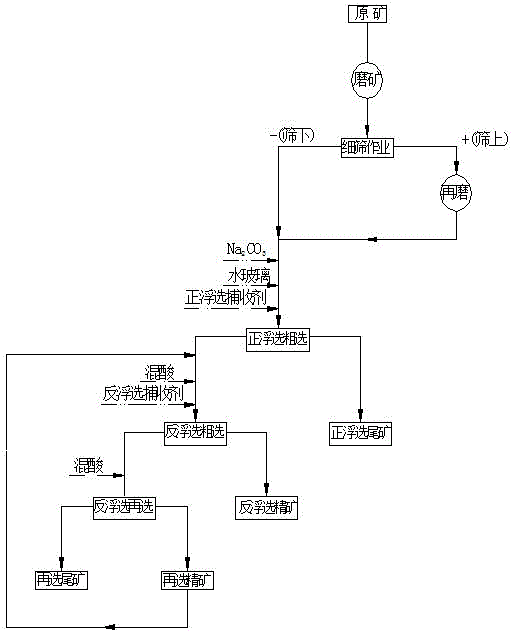

Image

Examples

Embodiment 1

[0038] Embodiment 1, a fine sieve regrinding mixed flotation method of low-grade siliceous-calcareous colloidal phosphate rock, its steps are as follows:

[0039] (1) Grind the low-grade siliceous calcareous colloidal phosphate rock to a fineness of -0.074mm, accounting for 60.00% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 30.00%;

[0040] (2) Screen the ground raw ore pulp with a fine sieve. The concentration of the screening operation is 30.00%, and the particle size of 0.074mm, 0.063mm, and 0.045mm is graded respectively. The concentration under the sieve is adjusted to 15.00%, and the concentration on the sieve is 45.00%. ;

[0041] (3) After regrinding the material on the sieve, the part with a fineness of -0.074mm accounts for 80% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 30.00%;

[0042] (4) Place the regrinded material on the sieve and t...

Embodiment 2

[0045] Embodiment 2, a fine sieve regrinding mixed flotation method of low-grade siliceous-calcareous colloidal phosphate rock, its steps are as follows:

[0046] (1) Grind the low-grade siliceous calcareous colloidal phosphate rock to a fineness of -0.074mm, accounting for 80.00% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 50.00%;

[0047] (2) Sieve the raw ore pulp from grinding with a fine sieve. The concentration of the sieving operation is 50.00%, and the particle sizes of 0.074mm, 0.063mm, and 0.045mm are graded respectively. The concentration under the sieve is adjusted to 35.00%, and the concentration on the sieve is 65.00%. ;

[0048] (3) After regrinding the material on the sieve, the part with a fineness of -0.074mm accounts for 95% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 40.00%;

[0049] (4) Place the regrinded material on the sieve...

Embodiment 3

[0052] Embodiment 3, a fine sieve regrinding mixed flotation method of low-grade siliceous-calcareous colloidal phosphate rock, the steps are as follows:

[0053] (1) Grind the low-grade siliceous calcareous colloidal phosphate rock to a fineness of -0.074mm, accounting for 65.00% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 35.00%;

[0054] (2) Screen the ground raw ore pulp with a fine sieve. The concentration of the screening operation is 35.00%, and the particle sizes of 0.074mm, 0.063mm, and 0.045mm are graded respectively. The concentration under the sieve is adjusted to 20.00%, and the concentration on the sieve is 50.00%. ;

[0055] (3) After regrinding the material on the sieve, the part with a fineness of -0.074mm accounts for 85% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 33.00%;

[0056] (4) Place the regrinded material on the sieve and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com