Belt-type dry magnetic separator

A magnetic separator and dry-type technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of waste of resources, low-grade products, etc., and achieve low-grade magnetic materials, high belt speed, and large processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

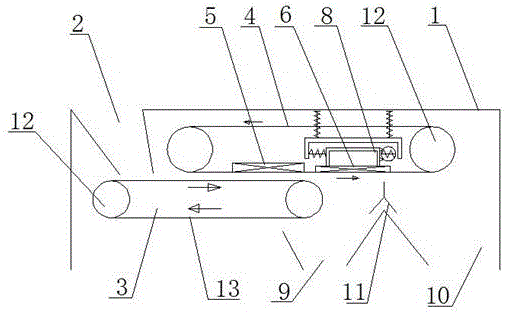

[0031] Such as figure 1 with figure 2 As shown, a belt dry magnetic separator includes:

[0032] The casing 1 is located outside the entire magnetic separator, and is used to cover all the parts in the magnetic separator to protect the magnetic separator and realize closed operation.

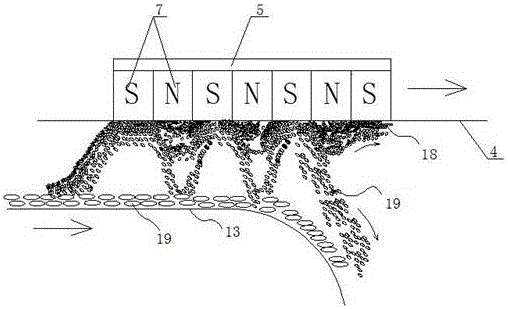

[0033] Feeding device 3, the upper side of the shell 1 is provided with a feeding port 2, and a feeding device 3 is provided below the feeding port 2, that is, the material directly falls on the feeding device 3 through the feeding port 2, and the feeding The device 3 includes a belt conveyor. The belt conveyor includes two rollers 12 and a conveyor belt 13 wound on two rollers. One of the two rollers 12 is an active roller and the other It is the driven roller. The driving roller can be an electric roller, such as an oil-cooled roller, or it can be replaced by an ordinary roller and a motor acceleration / decelerator, and the conveying belt 13 can be a high-strength non-magnetic belt. Along the mat...

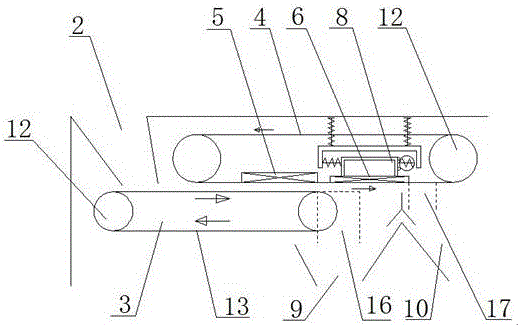

Embodiment 2

[0046] The second embodiment is the same as the first embodiment. The difference is that in the feeding device 3, the roller 12 on the side of the belt conveyor away from the feed port 2 is a magnetic roller, that is, the roller 12 of the belt conveyor The conveying end 16 is provided with a tail-throwing mechanism 14, a tailing port 9 is provided below the tail-throwing end of the tail-throwing mechanism 14, and a recovery port 15 is provided at the magnetic discharge end of the tail-throwing mechanism 14. Such as Figure 5 As shown, when the non-magnetic material on the belt conveyor is thrown at the conveying end 16, a very small amount of magnetic material is captured by the magnetic roller and adsorbed on the conveyor belt 13, and the non-magnetic material is collected by the tailing port 9. , The captured magnetic material moves with the conveyor belt 13. When the magnetic material moves away from the magnetic roller, the magnetic force on the magnetic material changes fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com