Patents

Literature

30results about How to "High belt speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing silicon solar cell

InactiveCN101783374ALow sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesMetallic electrodeOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the purpose of industrialized production better.

Owner:SUN EARTH SOLAR POWER

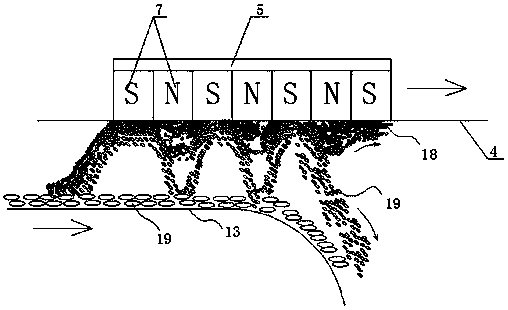

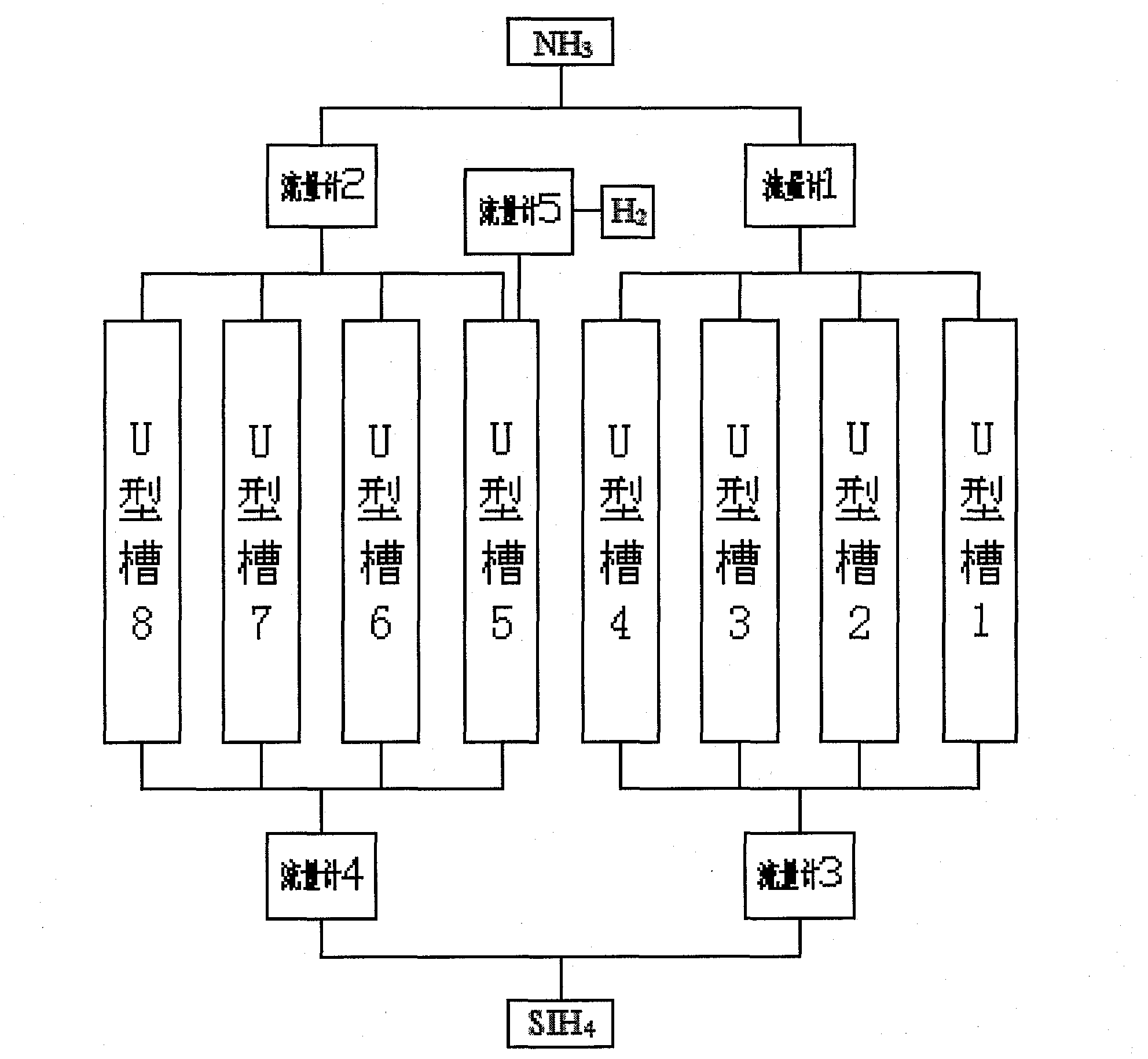

Preparation method of crystalline silicon solar cell

ActiveCN102244143AHigh belt speedControl thicknessFinal product manufactureChemical vapor deposition coatingBuilding integrationEtching

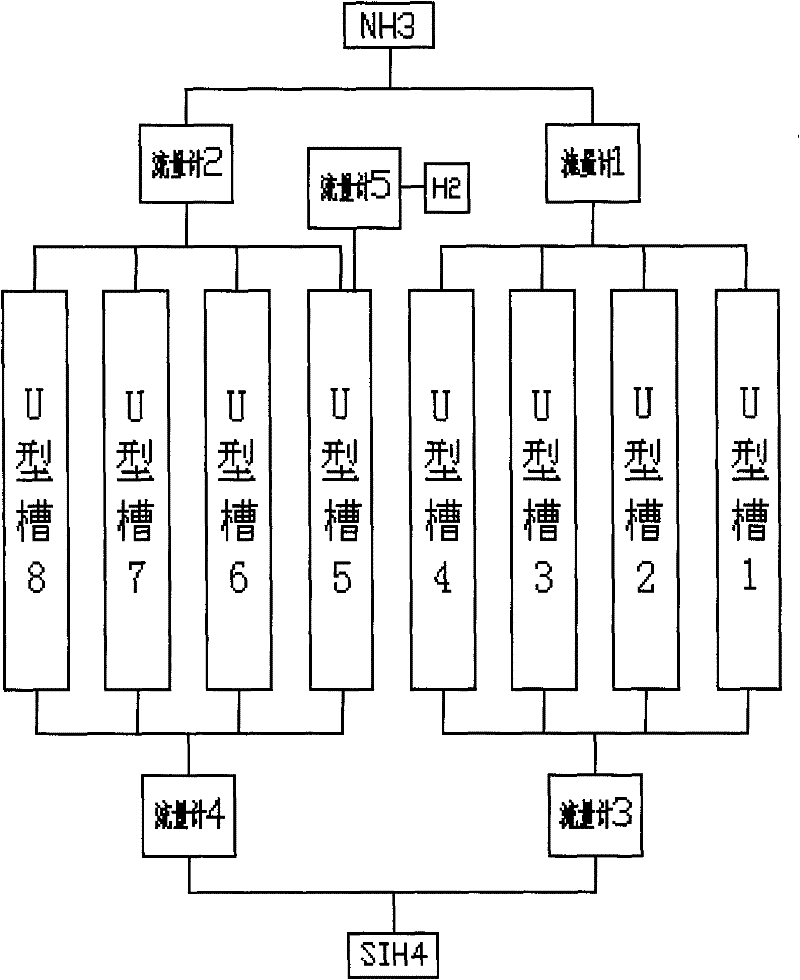

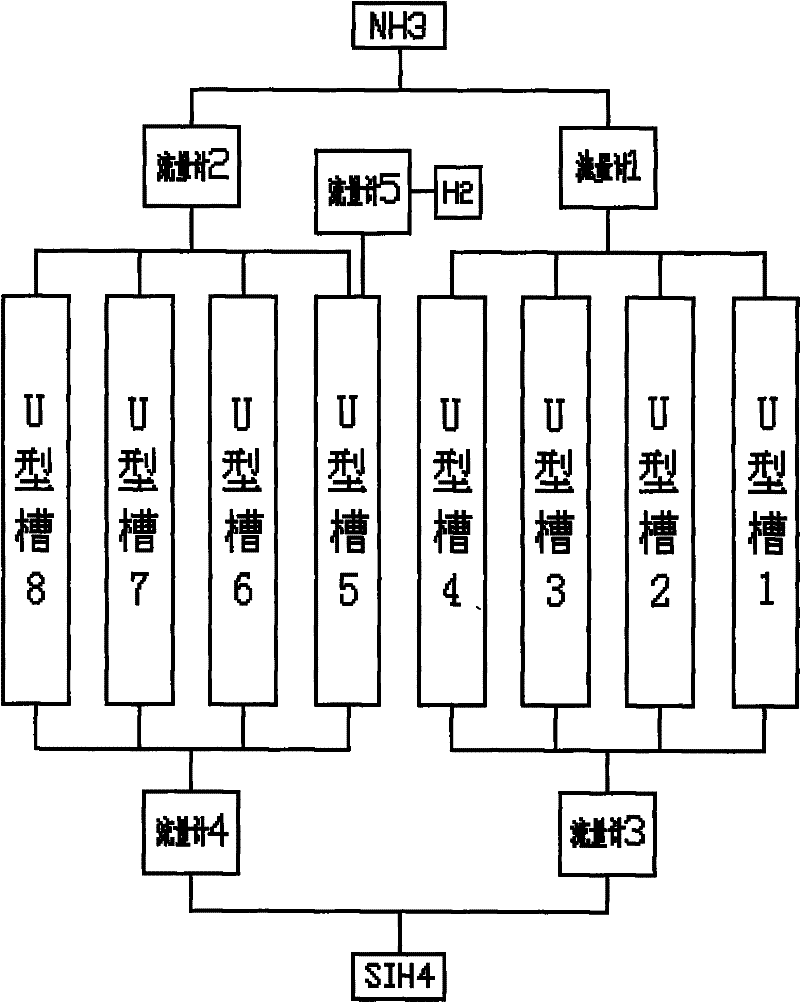

The invention discloses a preparation method of a crystalline silicon solar cell. The method comprises the following steps: 1, carrying out texture etching and diffusion on a raw material silicon wafer, wherein the depth of texture etching is controlled to be 0.2-1.0 mu m, the diffusion is controlled to be 0.1-0.2 mu m; 2, coating a silicon nitride antireflection film by using PECVD (plasma enhanced chemical vapor deposition) equipment, wherein the flow ratio of ammonia gas NH3 and silane SIH4 entering into the first four U-shaped grooves of the PECVD equipment is 6:5; the flow ratio of ammonia gas NH3 and silane SIH4 entering into the last four U-shaped grooves of the PECVD equipment is 3:1-4:1; hydrogen H2 with gas flow of 200-300Sccm is charged in the five U-shaped groove in all the U-shaped grooves; the color of the film of which the thickness is controlled to be 20-40nm is yellow, the color of the film of which the thickness is controlled to be 40-60nm is red, and the color of the film of which the thickness is controlled to be 100-120nm is green. According to the invention, through changing the total amount of the gas entering all the U-shaped grooves of the PECVD equipment,the thickness of the antireflection film can be controlled, and then the cell can show red, green and yellow, so that the demand for the integration of photovoltaic products and buildings can be satisfied. The invention has the advantages of increasing output, reducing the flows of ammonia gas NH3, silane SIH4 and hydrogen H2, improving production efficiency and lowering the cost.

Owner:BAODING GUANGWEI GREEN ENERGY TECH CO LTD

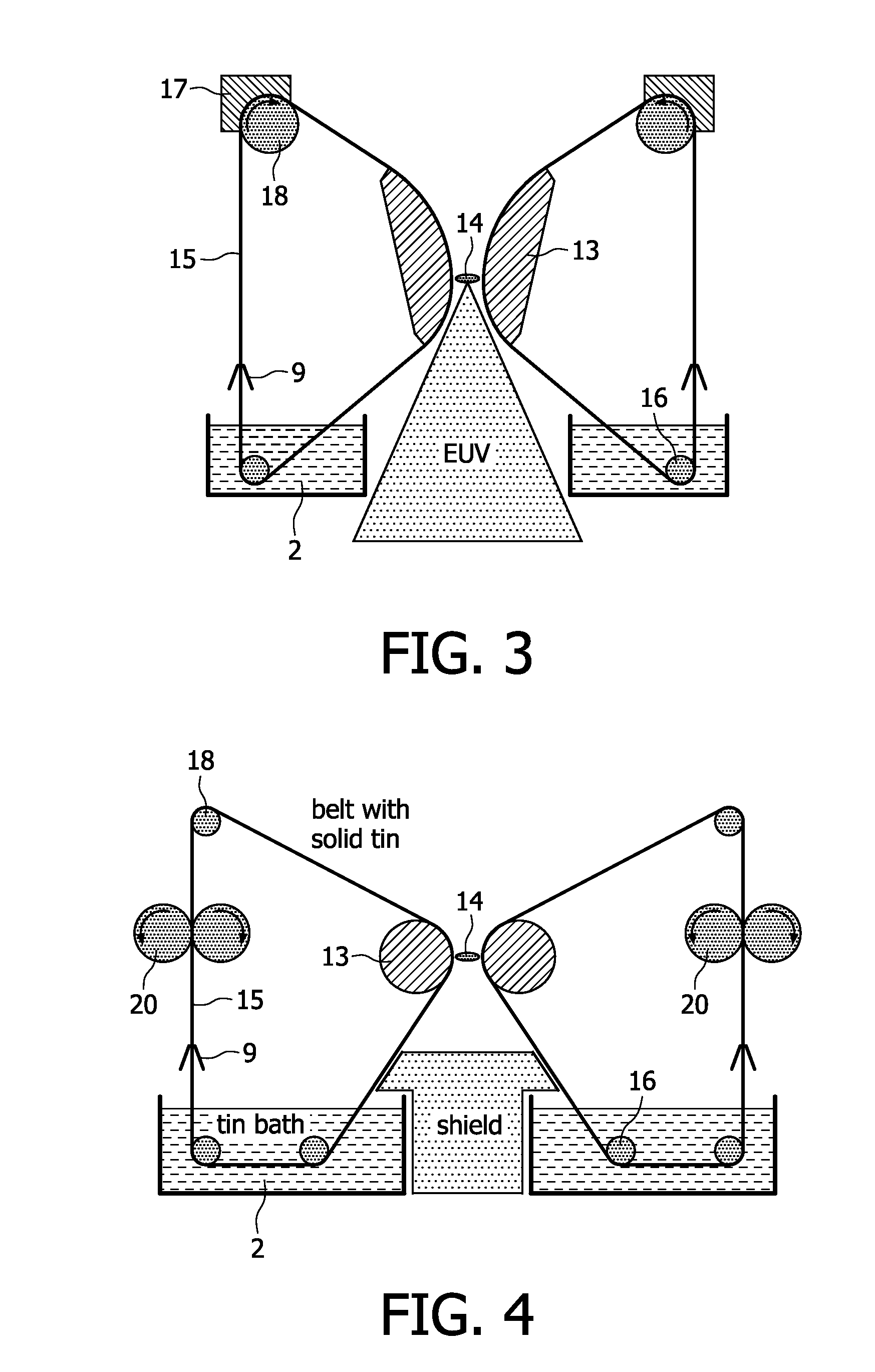

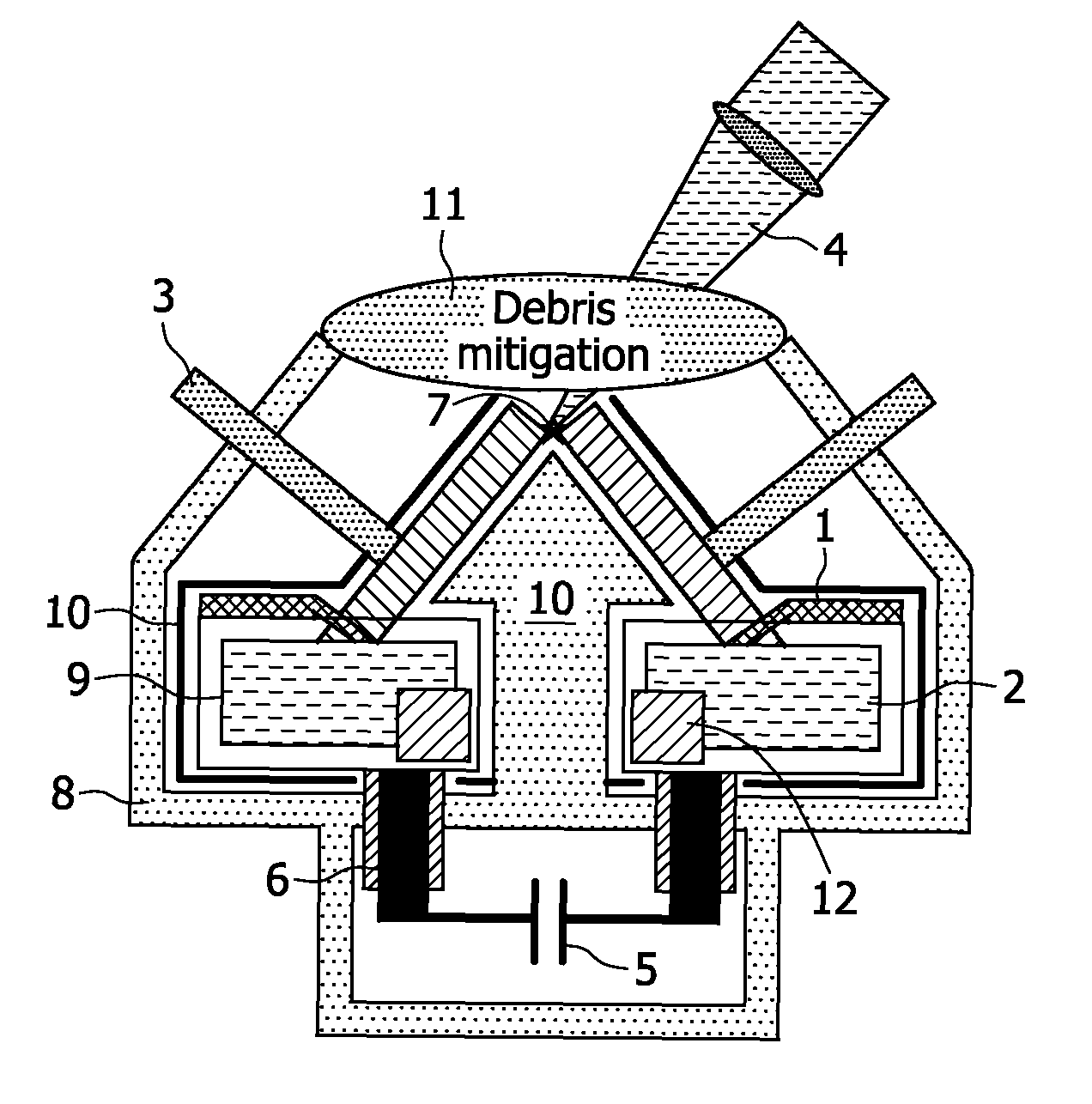

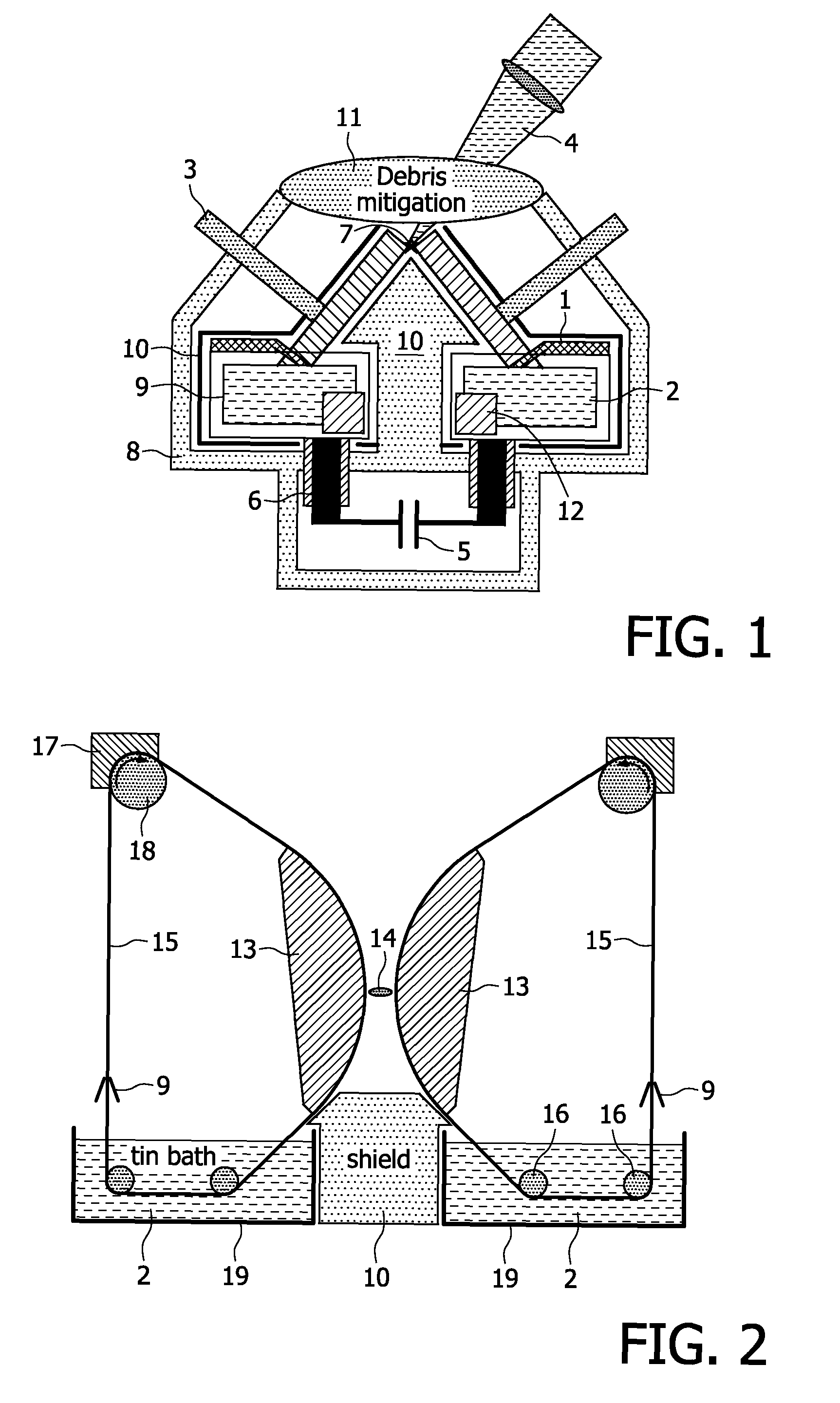

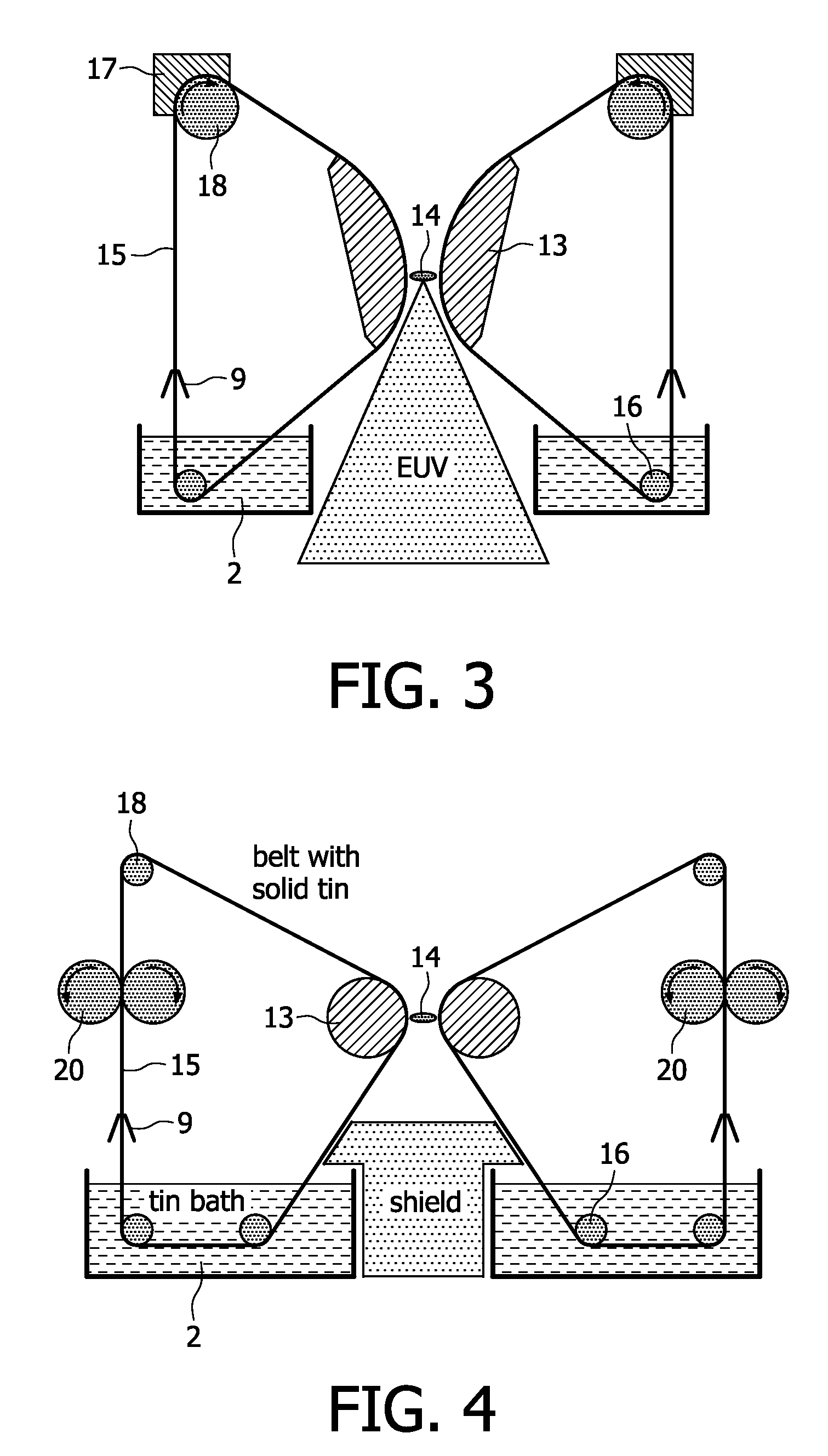

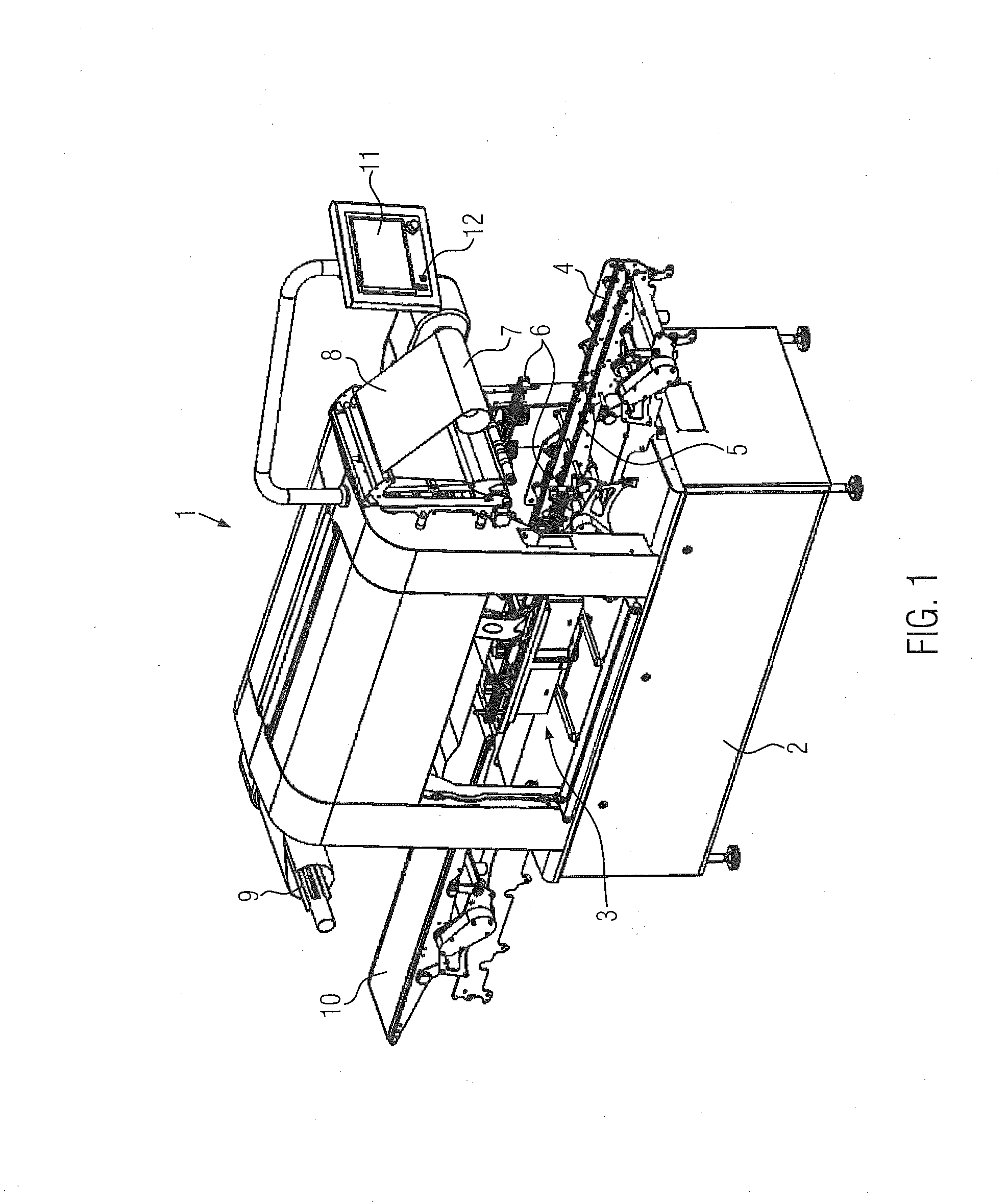

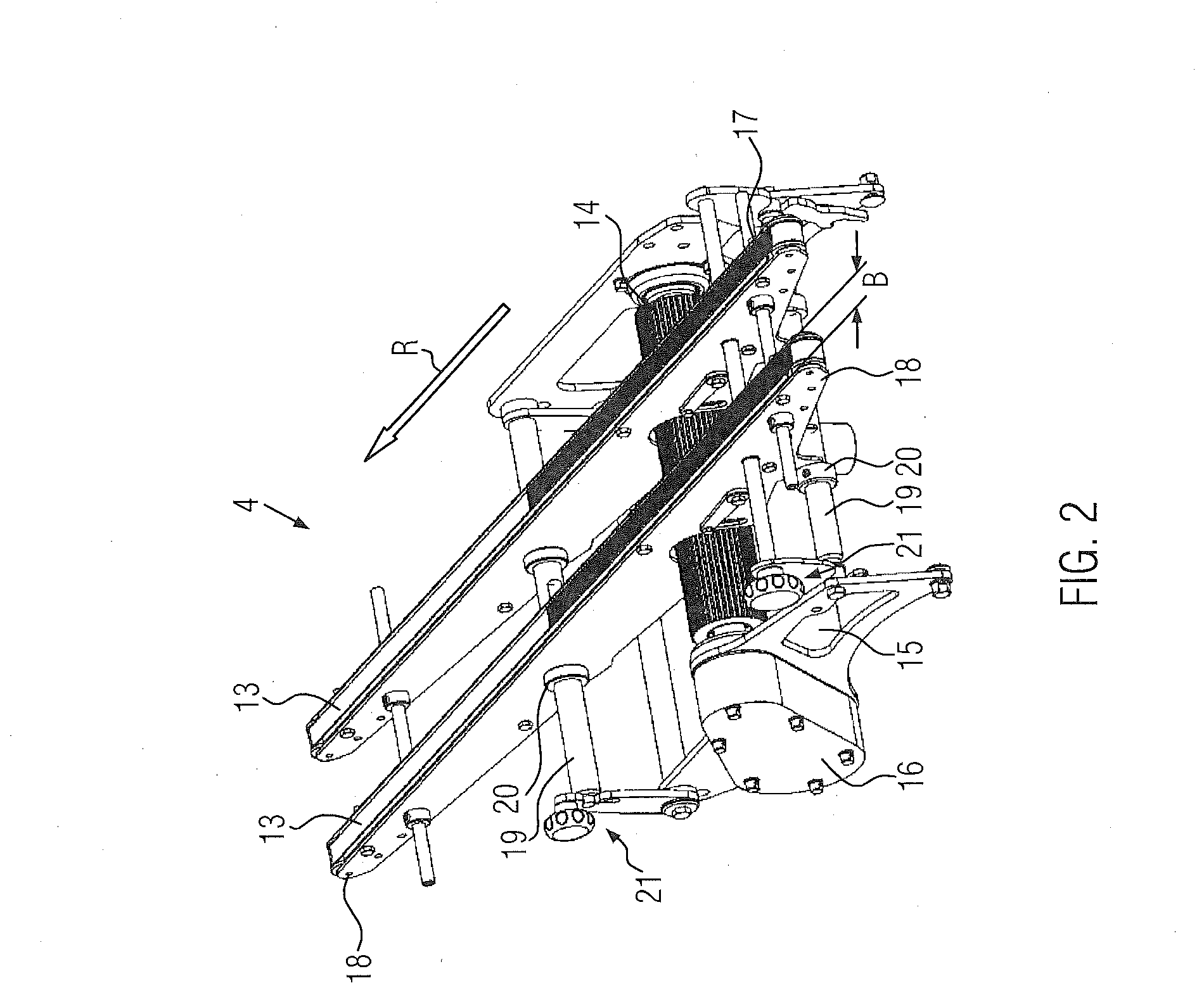

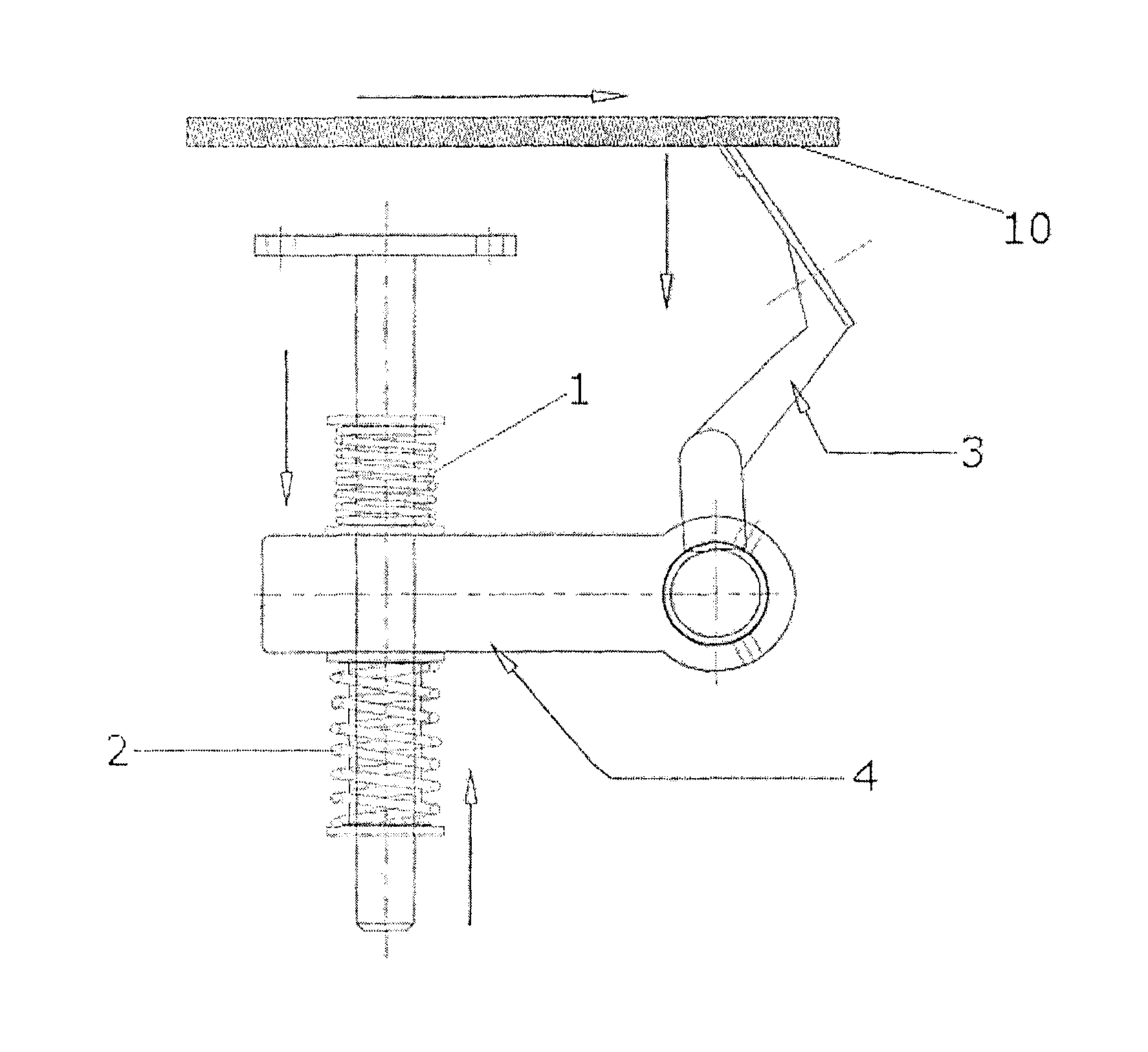

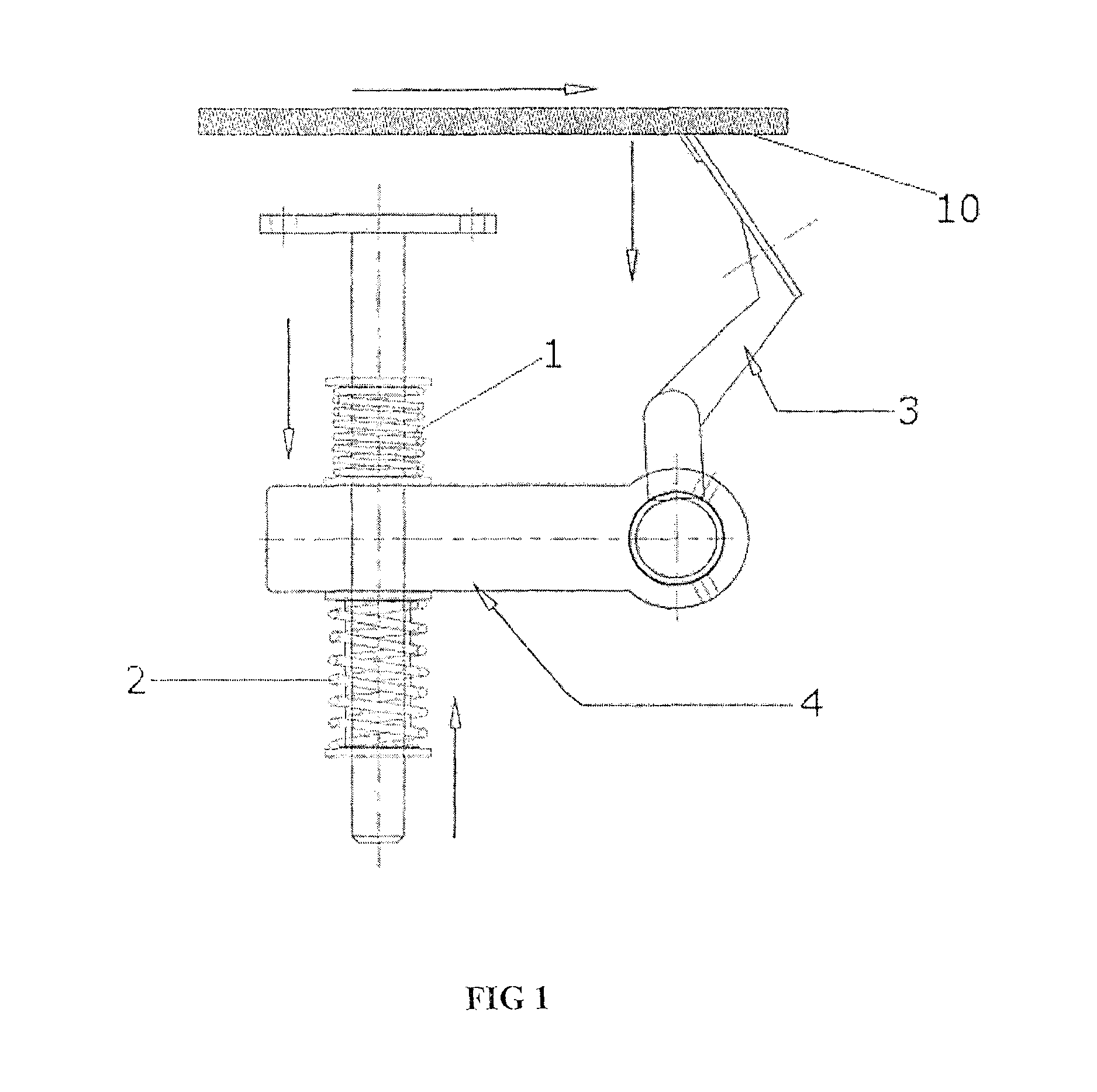

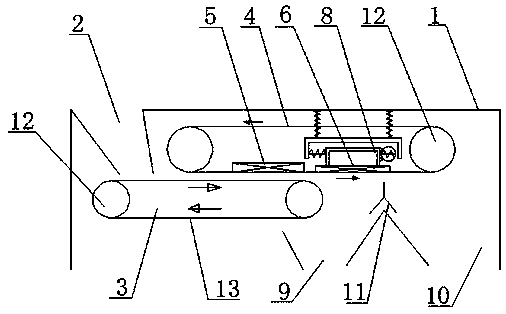

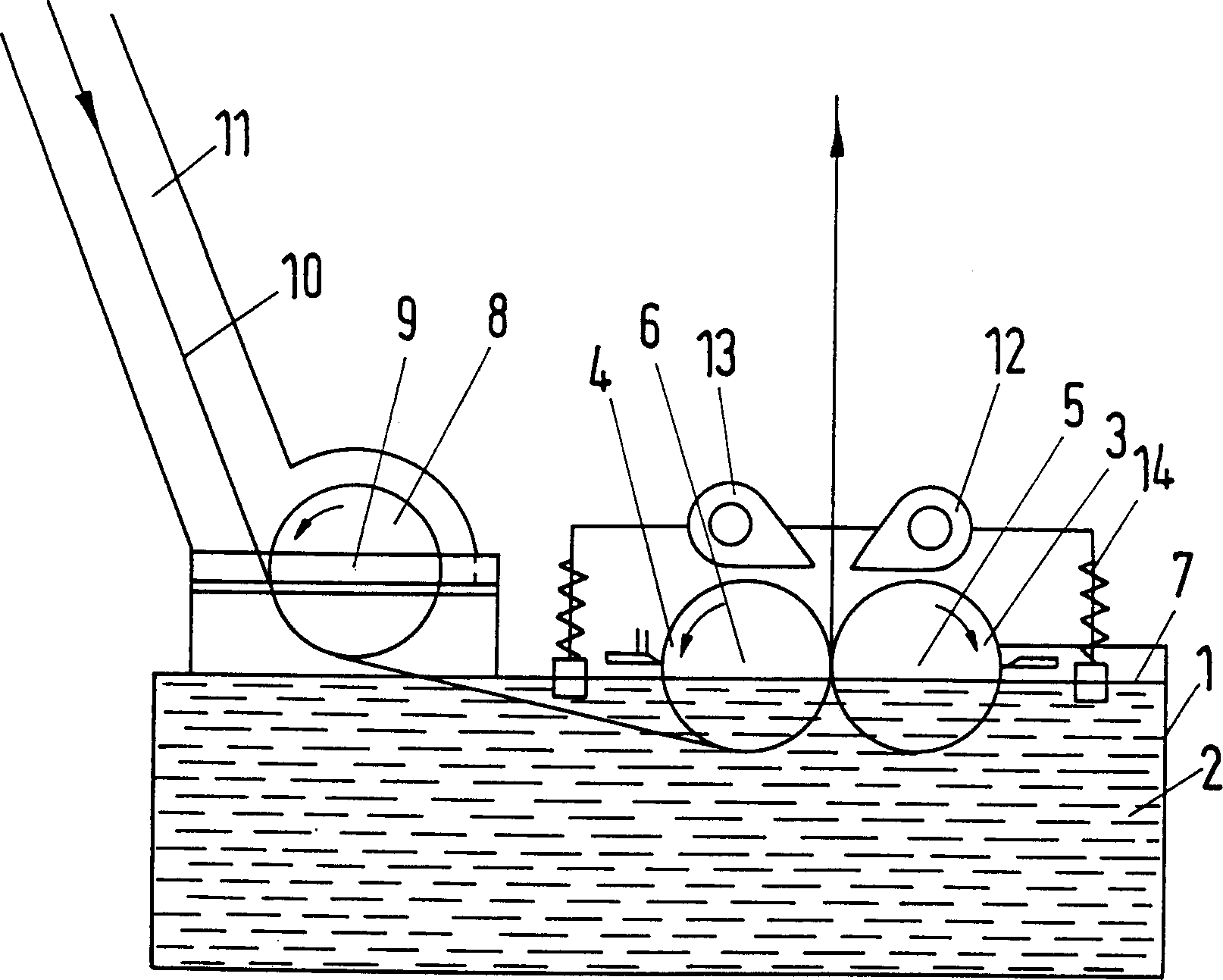

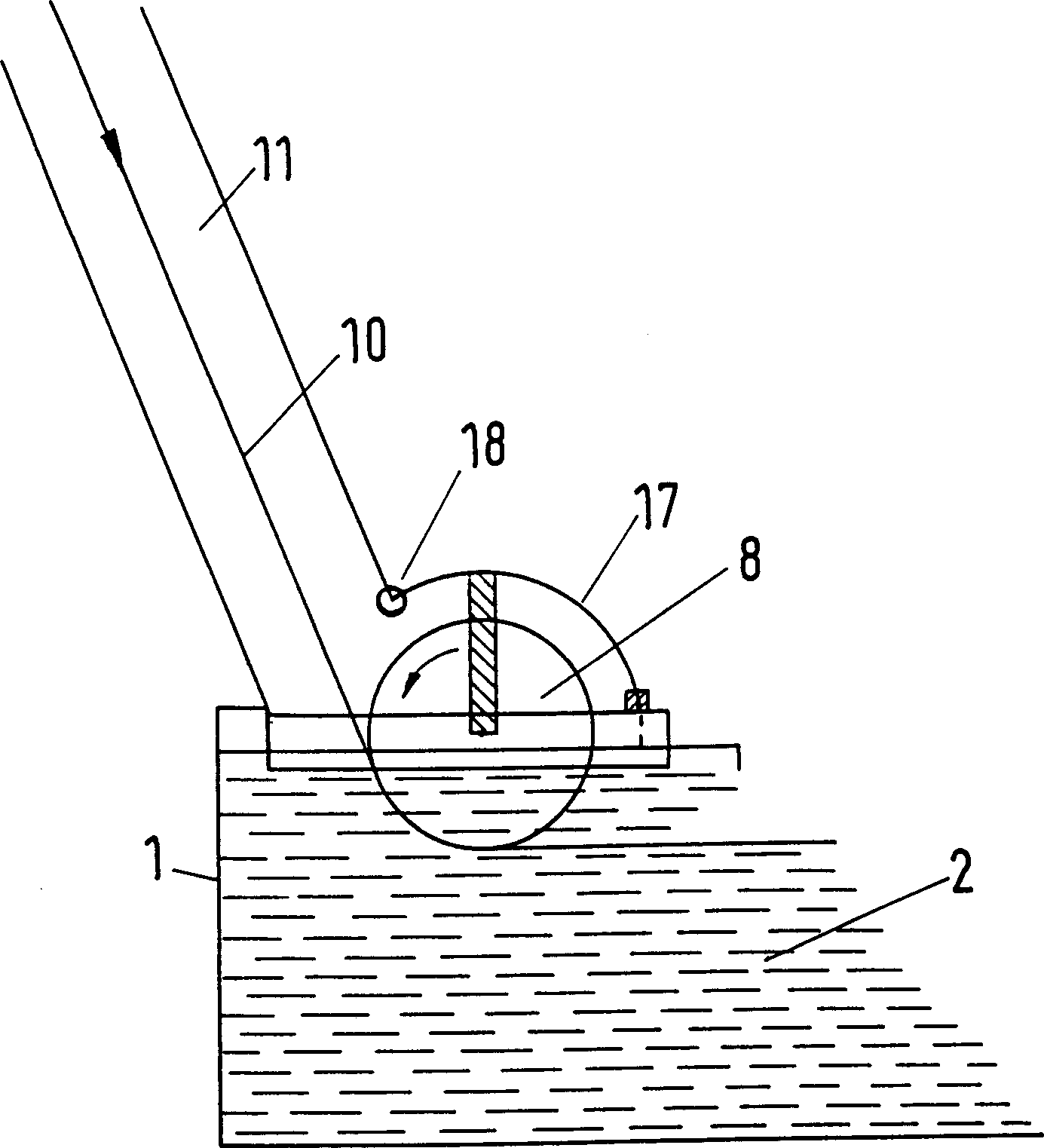

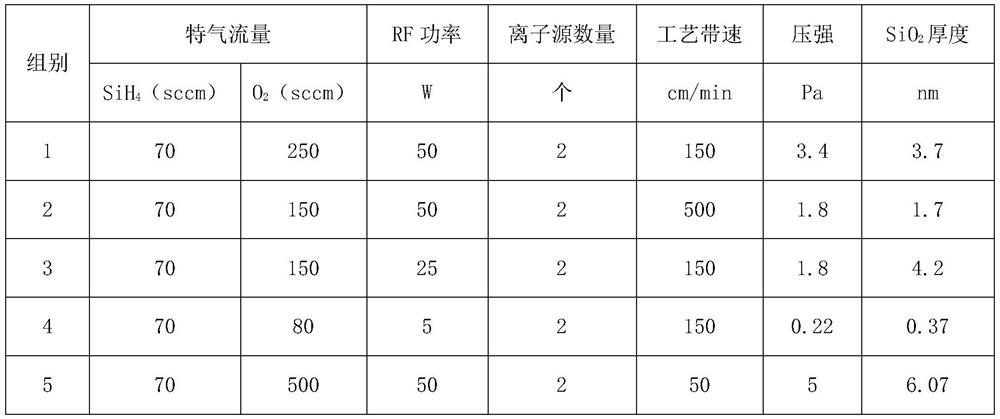

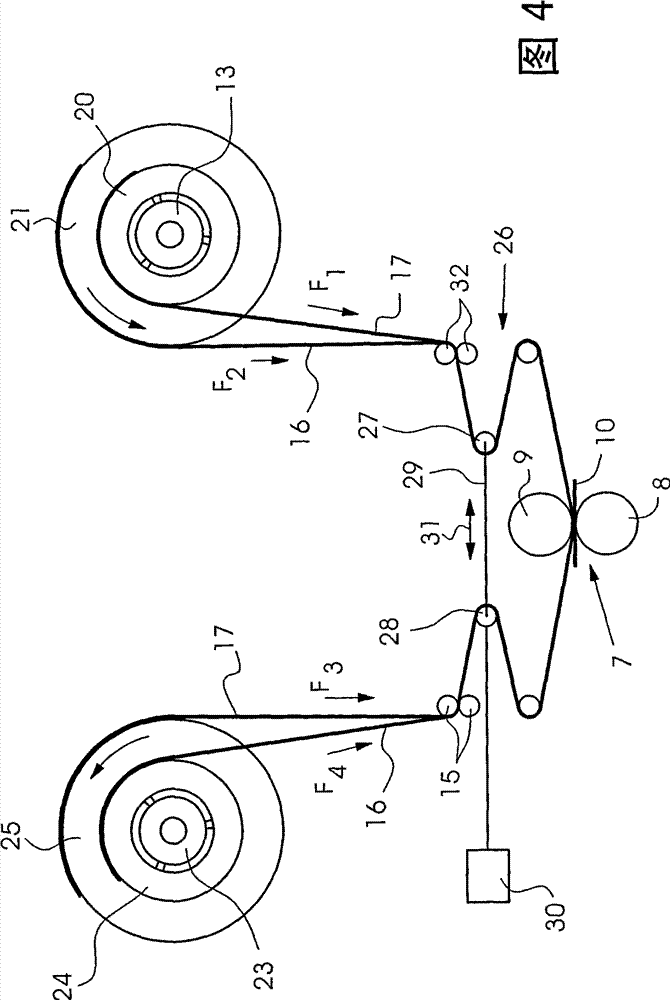

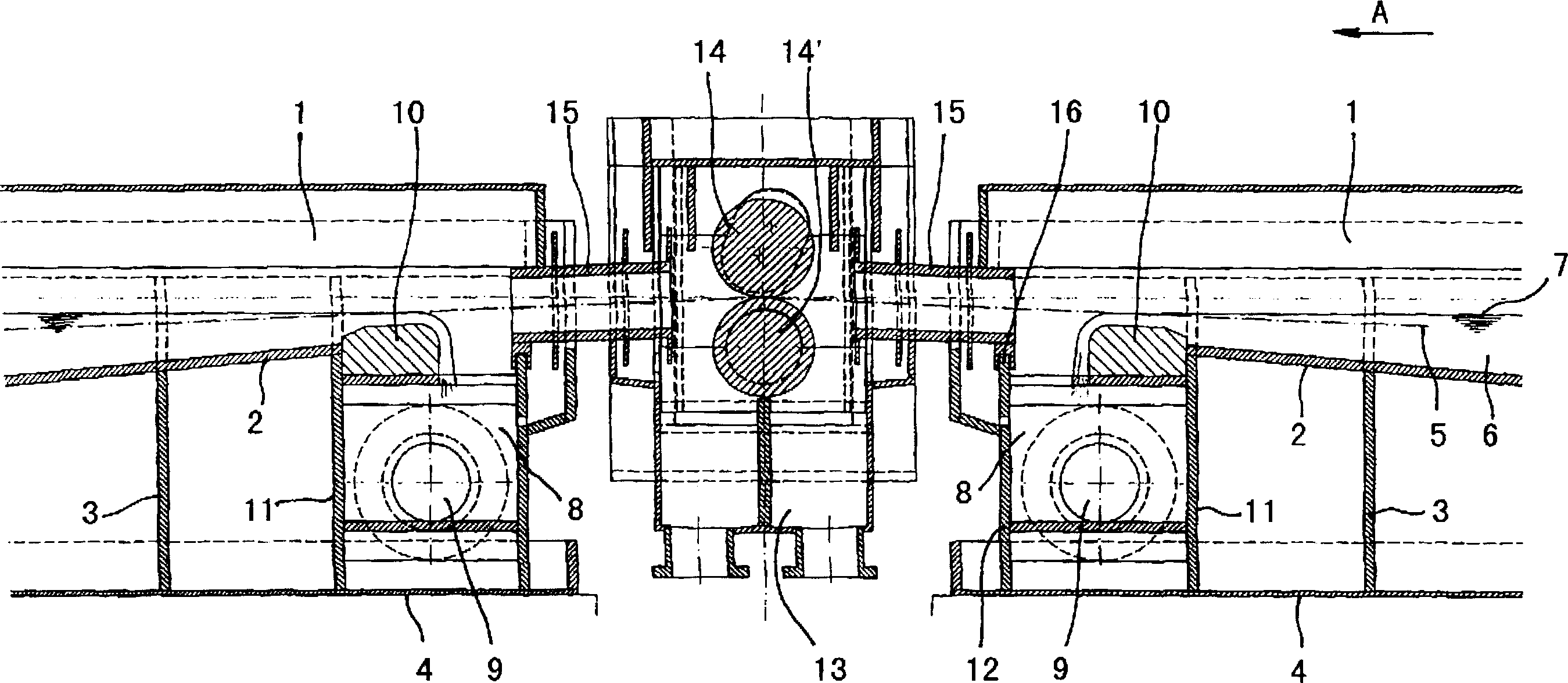

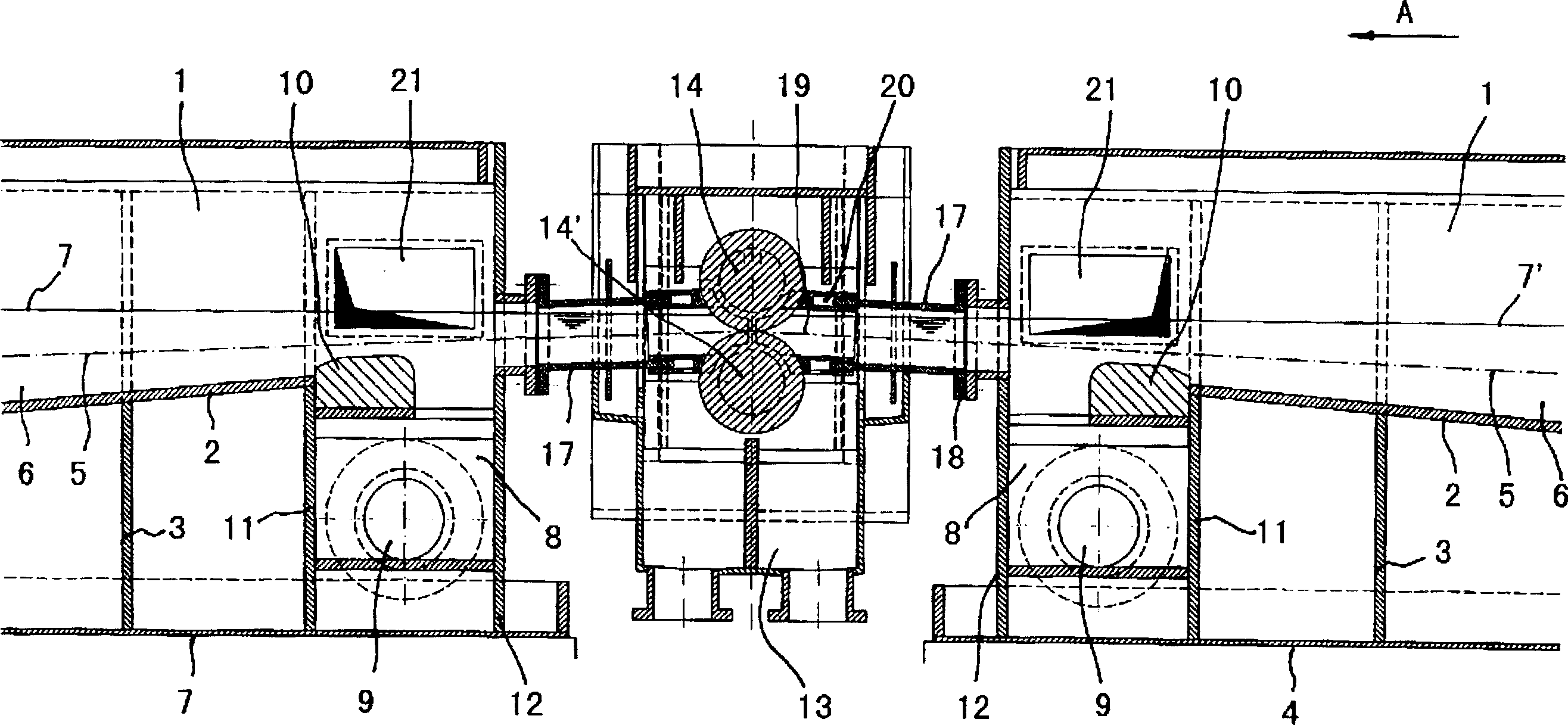

EUV plasma discharge lamp with conveyor belt electrodes

ActiveUS20090250638A1More compact designIncrease input powerX-ray tube with very high currentGaseous cathode lampsSoft x rayGas-discharge lamp

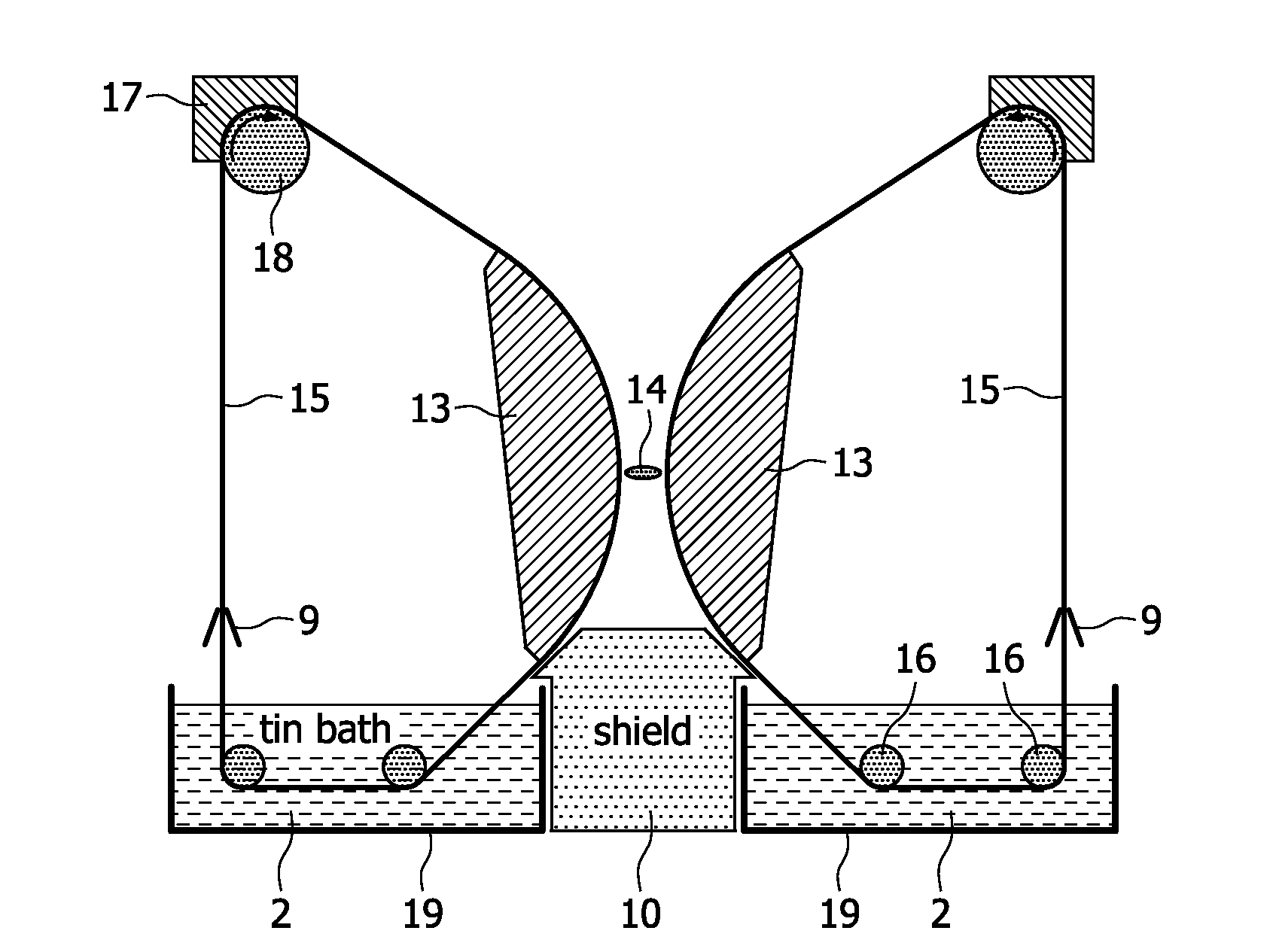

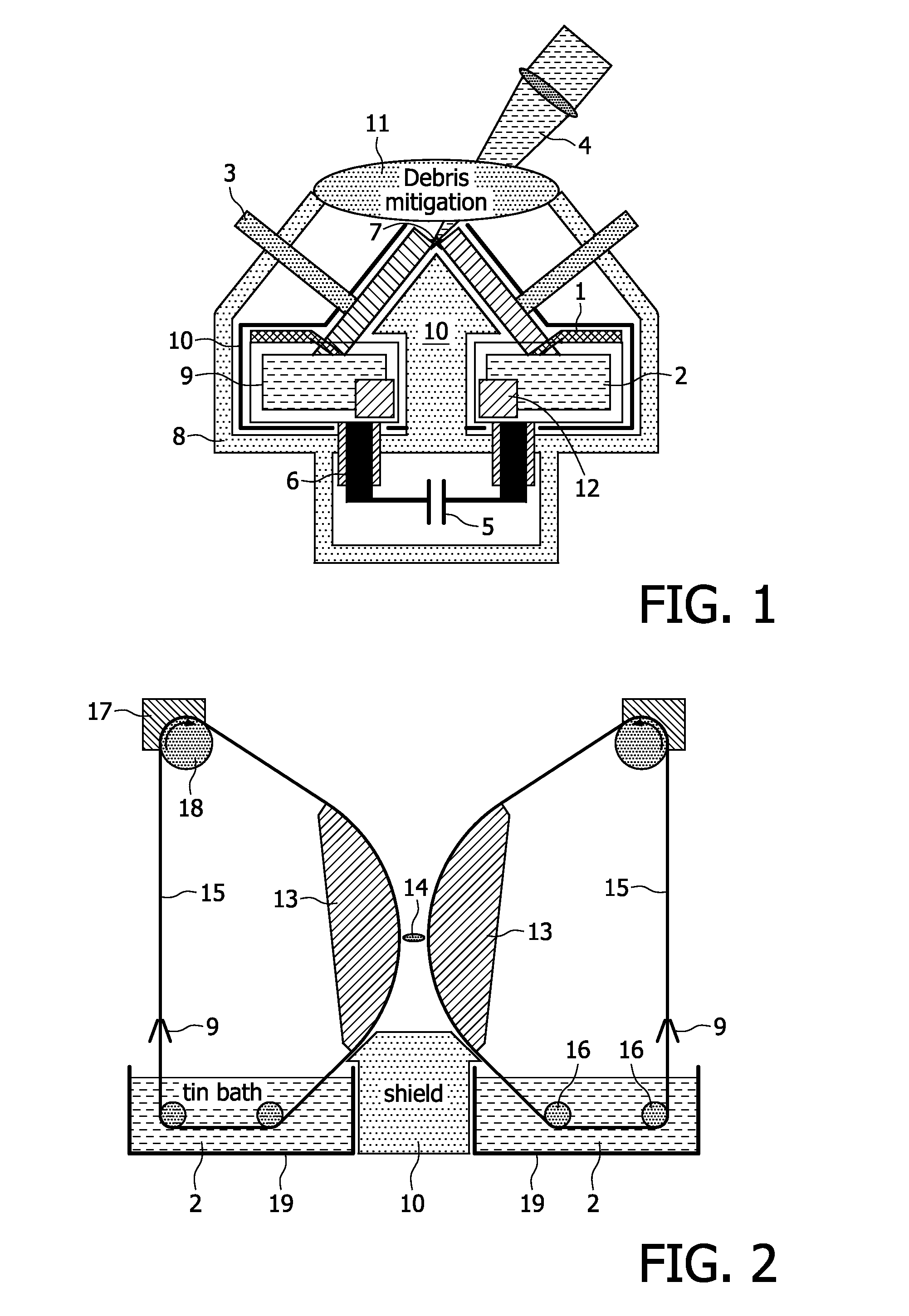

The present invention relates to a plasma discharge lamp for generating EUV radiation and / or soft X-rays by means of an electrically operated discharge. The proposed lamp comprises at least two electrodes arranged in a discharge space at a distance from one another to form a gap which allows the ignition of a plasma (14) in a gaseous medium between said electrodes. A metal applying device applies a metal to a surface of said electrodes. The electrodes are formed of conveyer belts (15) driven to transport the metal to said gap, wherein for each of the electrodes a shaper element (13) is provided at the gap to ensure a proper form and distance of the electrodes at the gap. An energy beam device (4) is adapted to direct an energy beam onto at least one of said surfaces in the gap evaporating said applied metal at least partially thereby producing said gaseous medium. With the proposed plasma discharge lamp high input powers can be achieved at a compact design of the lamp.

Owner:USHIO DENKI KK

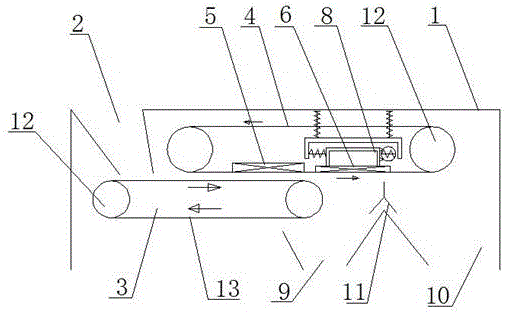

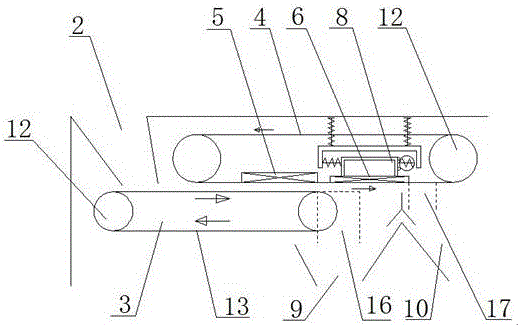

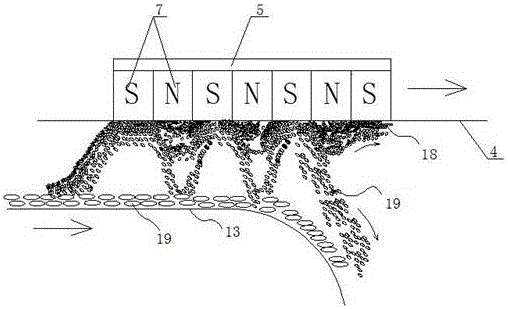

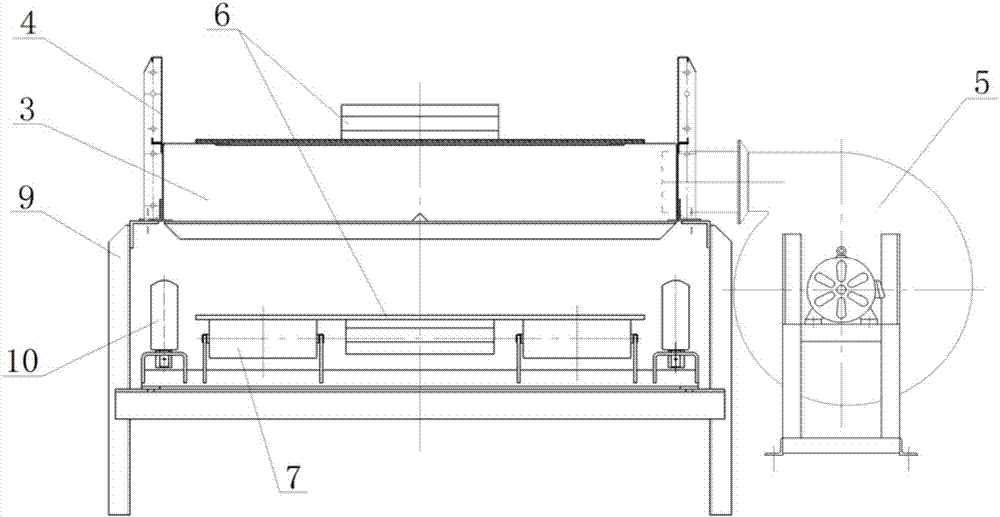

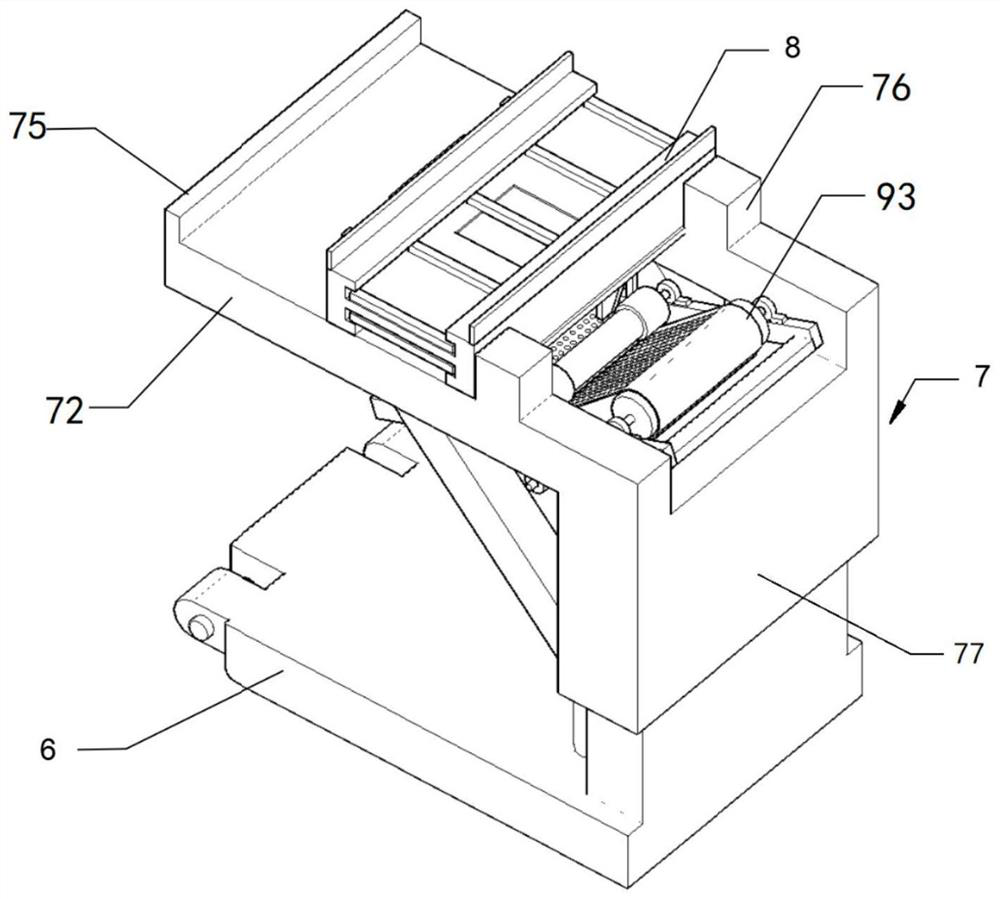

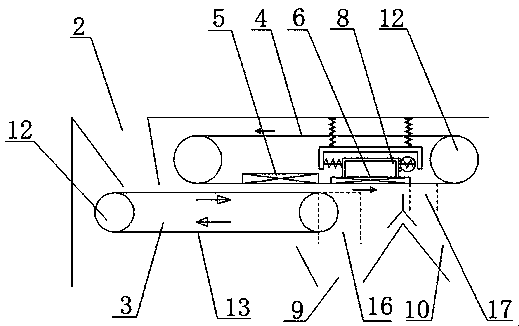

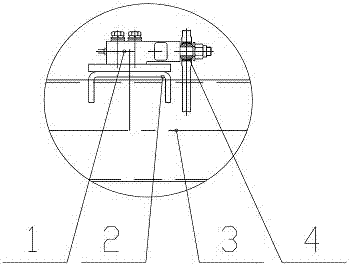

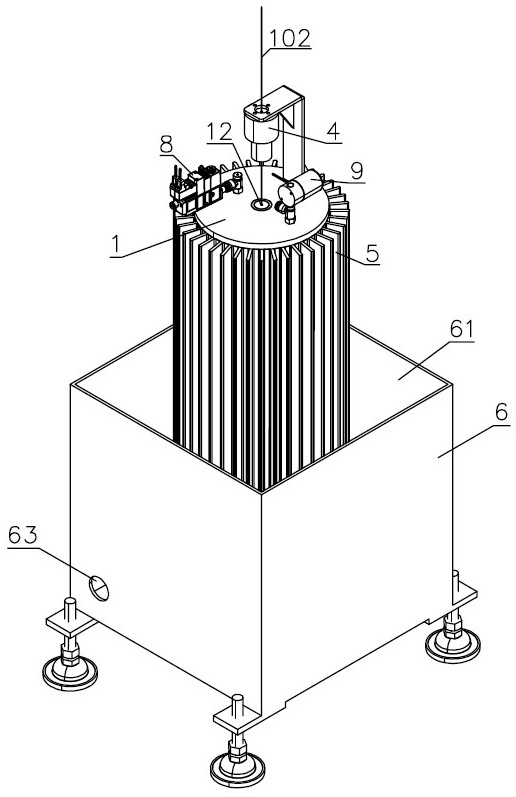

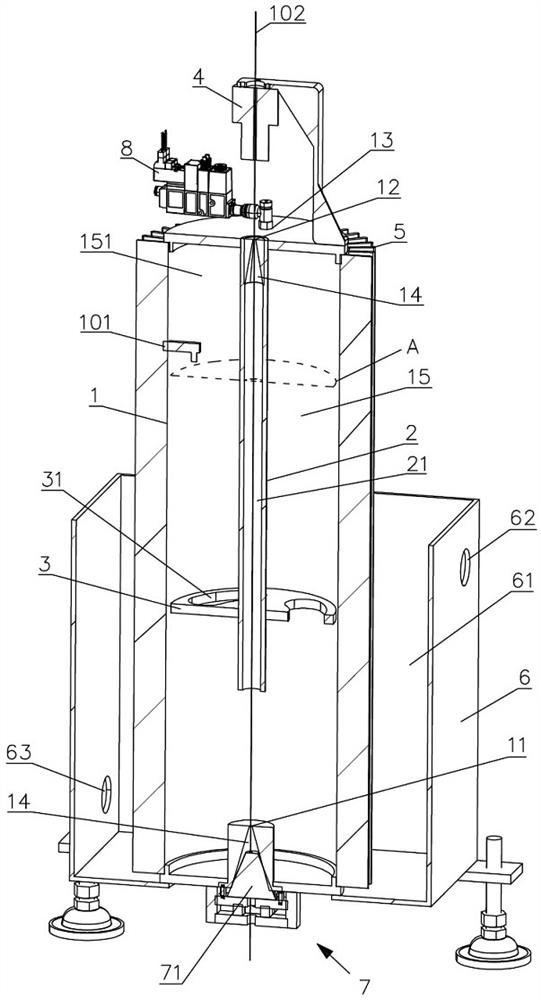

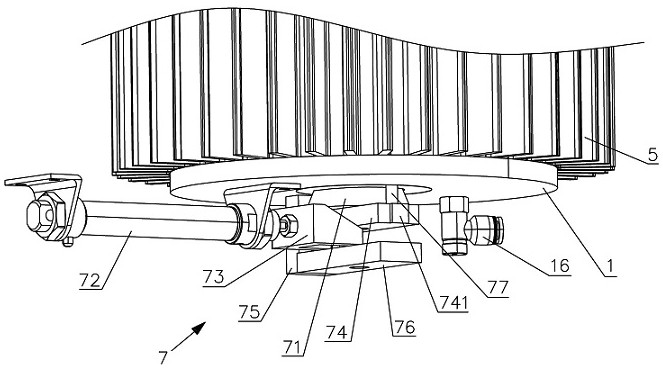

Belt-type dry magnetic separator

ActiveCN106000636AEasy to handleHigh belt speedMagnetic separationMagnetic separatorMineral particles

The invention discloses a belt-type dry magnetic separator. The belt-type dry magnetic separator comprises a housing, the upper part of the housing is provided with a feeding inlet, a feeding device is arranged below the feeding inlet, a magnetic separation device is arranged above the feeding device, the magnetic separation device comprises a magnetic separation belt, along a material conveying direction of the feeding device, a primary separation magnetic system and a refined separation magnetic system are orderly arranged in the magnetic separation belt in parallel, a conveying tail end of the feeding device is not in a magnetic material discharge range of the refined separation magnetic system, a magnetic field range of the primary separation magnetic system covers materials on the feeding device, a magnetic field of the refined separation magnetic system is an alternating magnetic field, and magnetic field ranges of the primary separation magnetic system and the refined separation magnetic system are superimposed. The belt-type dry magnetic separator continuously treats a crushed magnetic material so that a product with quality close to that of water separated products is obtained, strictly controls mine tailing magnetic object quality, has a high treatment capability and a large tailings discarding rate, has a very wide mineral particle fraction application range and reduces a later technical equipment investment and a system operation cost.

Owner:CHENGDU LEEJUN TECH CO LTD

EUV plasma discharge lamp with conveyor belt electrodes

ActiveUS7897948B2Design moreIncrease input powerRadiation pyrometryX-ray tube with very high currentSoft x rayGas-discharge lamp

The present invention relates to a plasma discharge lamp for generating EUV radiation and / or soft X-rays by means of an electrically operated discharge. The proposed lamp comprises at least two electrodes arranged in a discharge space at a distance from one another to form a gap which allows the ignition of a plasma (14) in a gaseous medium between said electrodes. A metal applying device applies a metal to a surface of said electrodes. The electrodes are formed of conveyer belts (15) driven to transport the metal to said gap, wherein for each of the electrodes a shaper element (13) is provided at the gap to ensure a proper form and distance of the electrodes at the gap. An energy beam device (4) is adapted to direct an energy beam onto at least one of said surfaces in the gap evaporating said applied metal at least partially thereby producing said gaseous medium. With the proposed plasma discharge lamp high input powers can be achieved at a compact design of the lamp.

Owner:USHIO DENKI KK

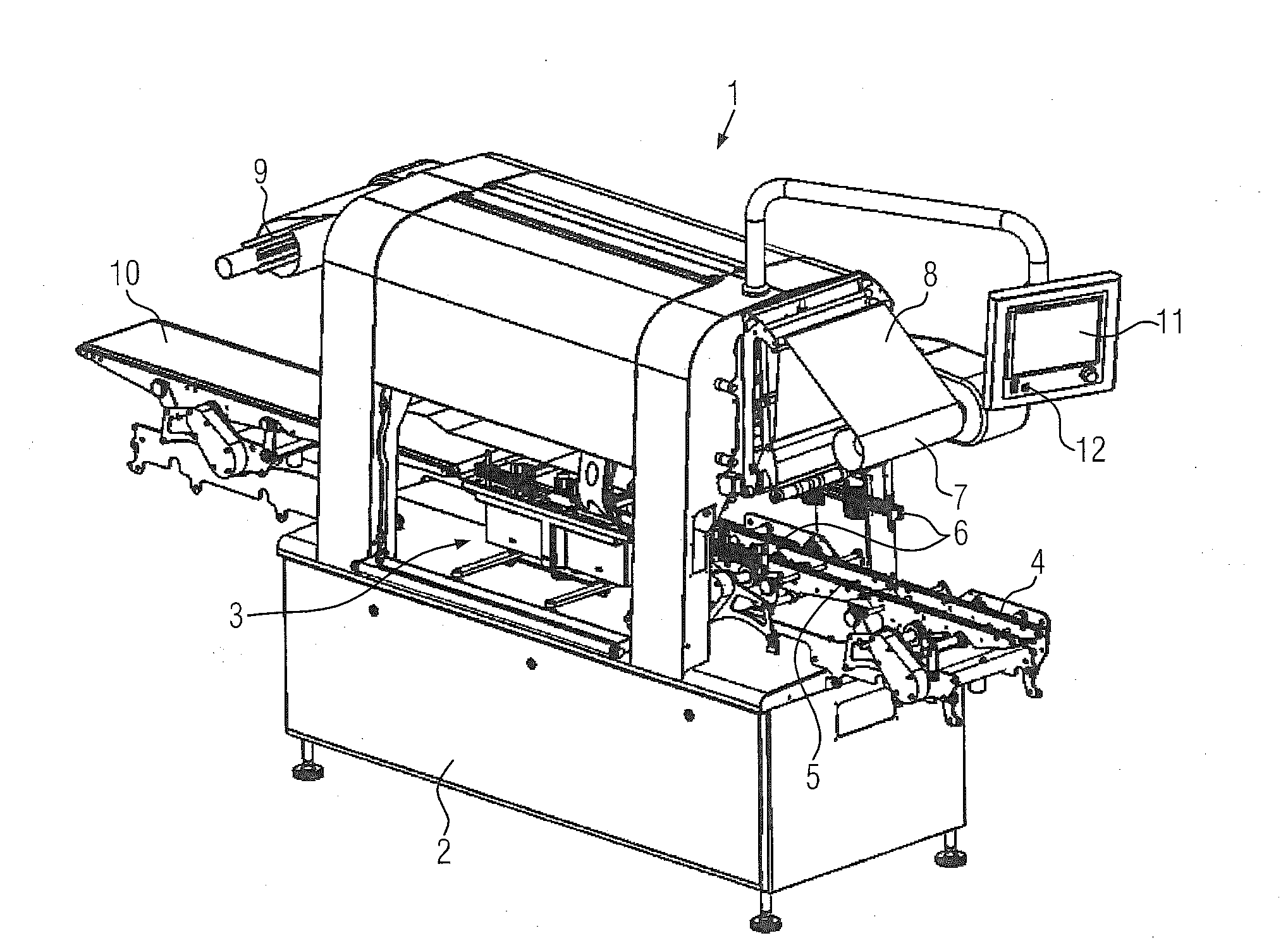

Tray sealer

InactiveUS20130008133A1Faster and easy to cleanIncrease frictionConveyorsPackagingEngineeringMechanical engineering

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Coating material, coating and aluminum foil

InactiveUS20050058827A1Solve effective useEfficient use ofGlass/slag layered productsSpecial surfacesCross-linkFilling materials

A coating material, in particular for high temperature applications, comprises a binding agent and at least one filler material, which can be deposited on a metal surface. For this, the binding agent contains at least one siloxane with an organic residual share of less than 25 weight %. It is preferable if the siloxane or siloxanes is (are) cross-linked three and / or four times.

Owner:NANOX

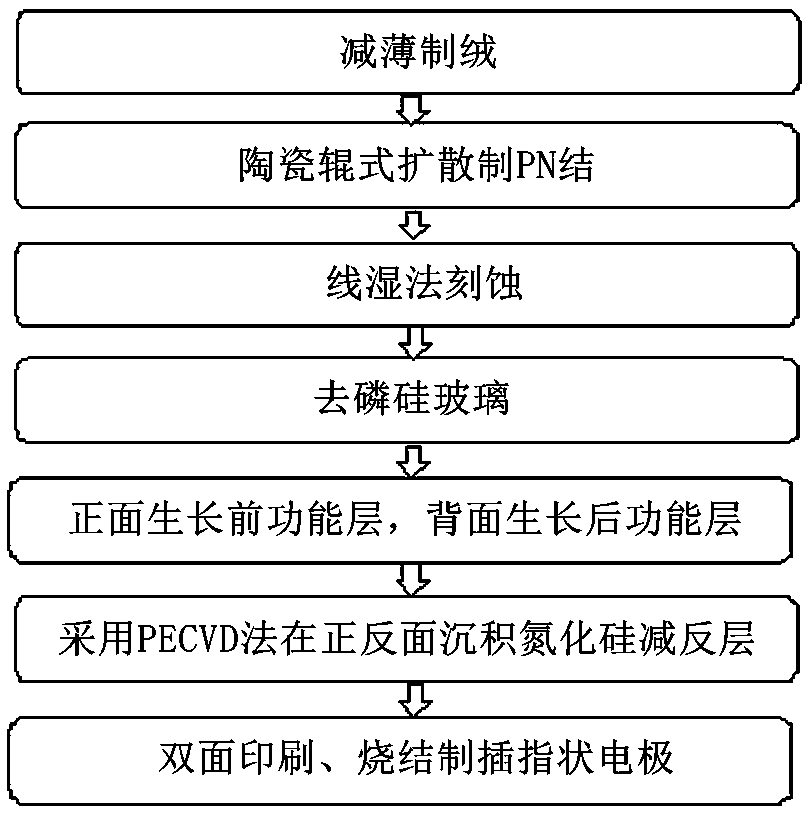

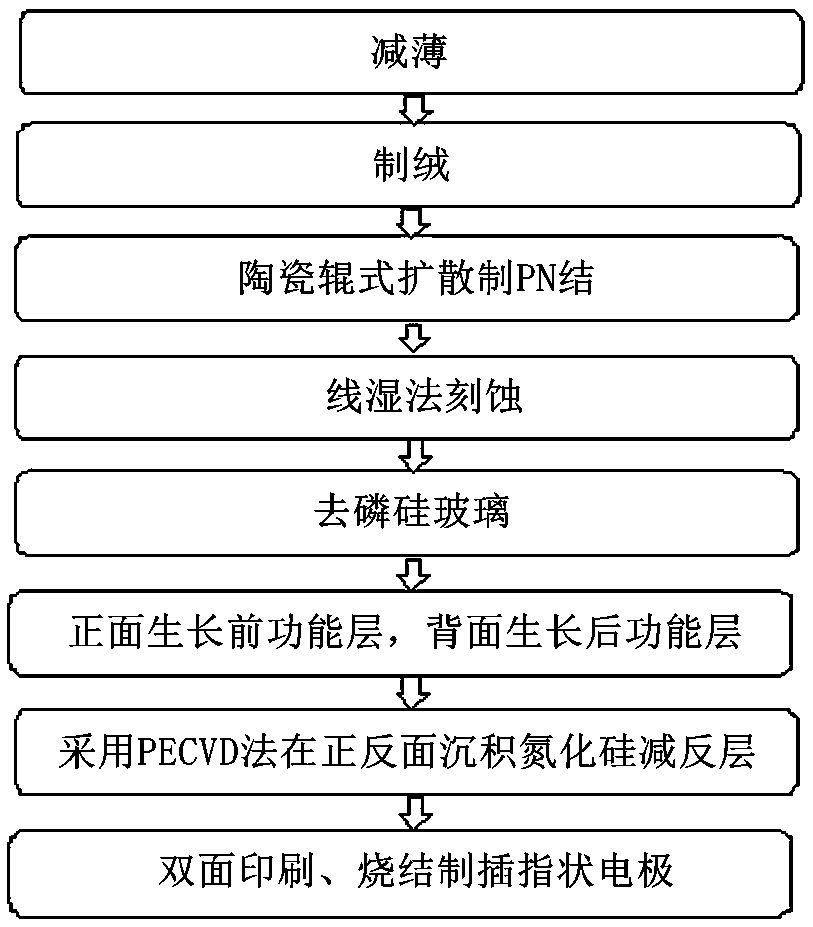

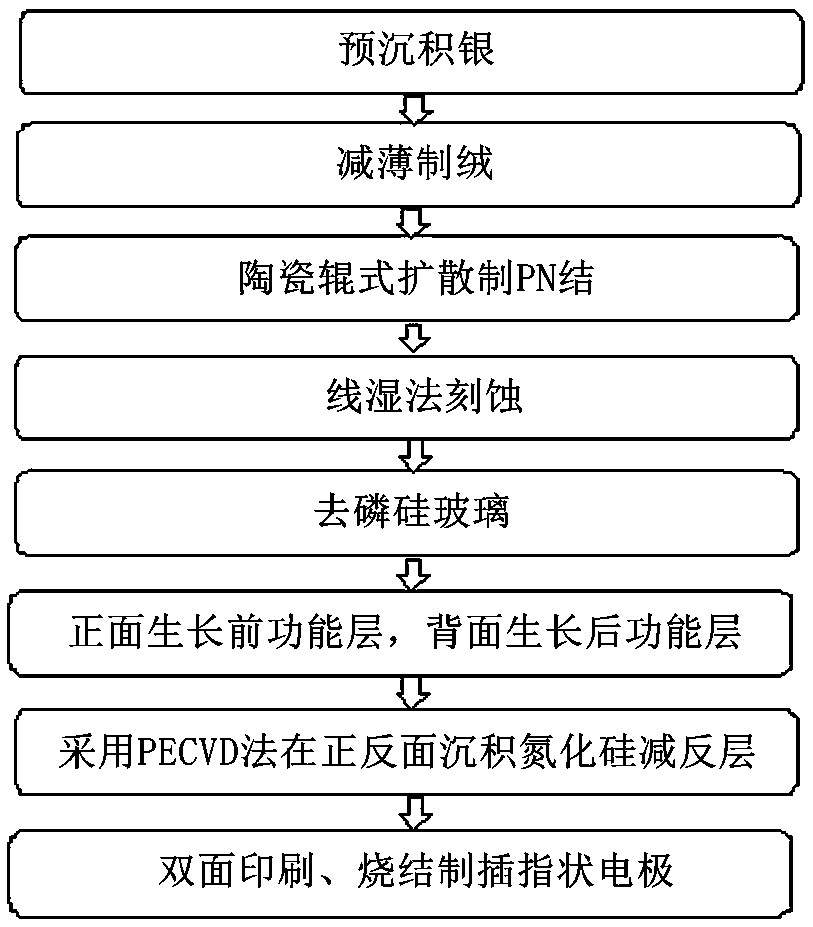

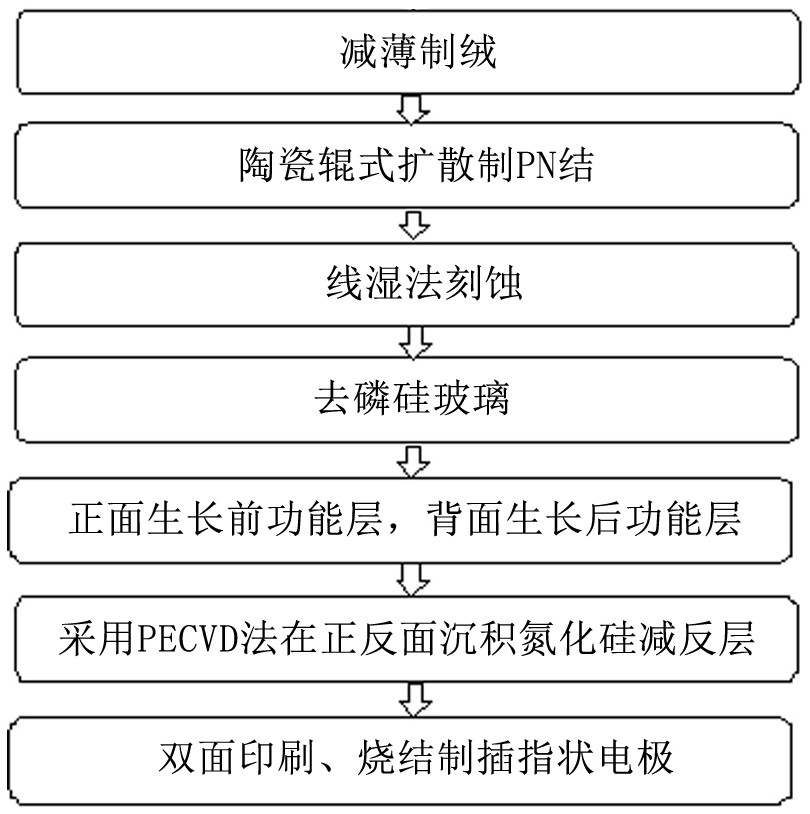

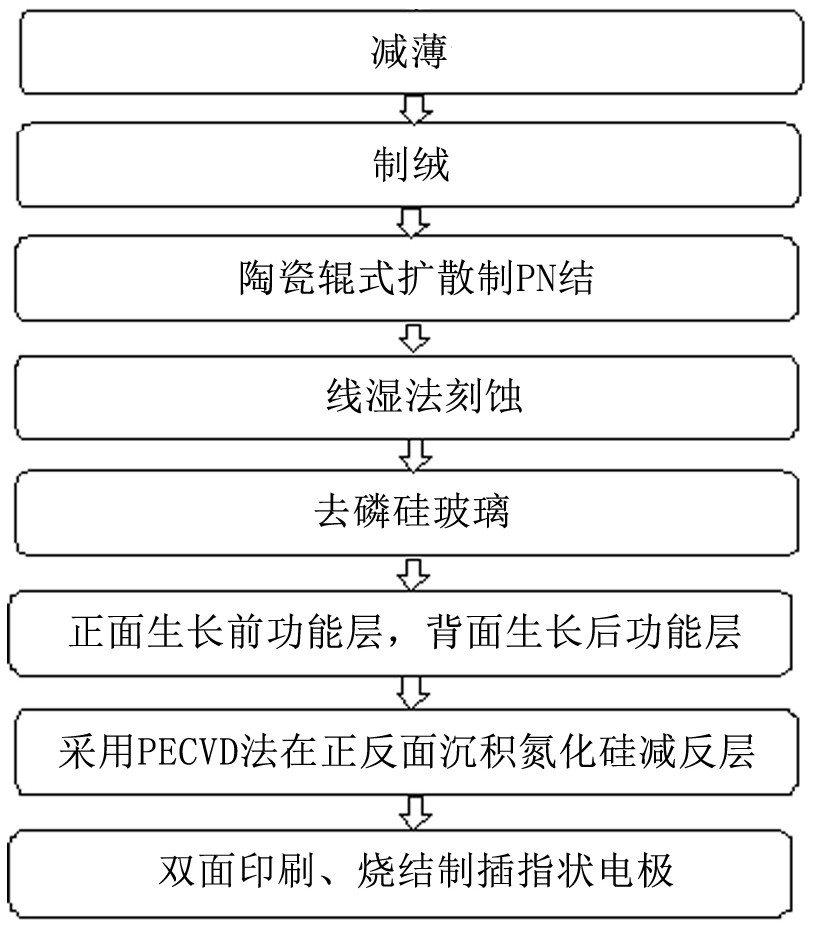

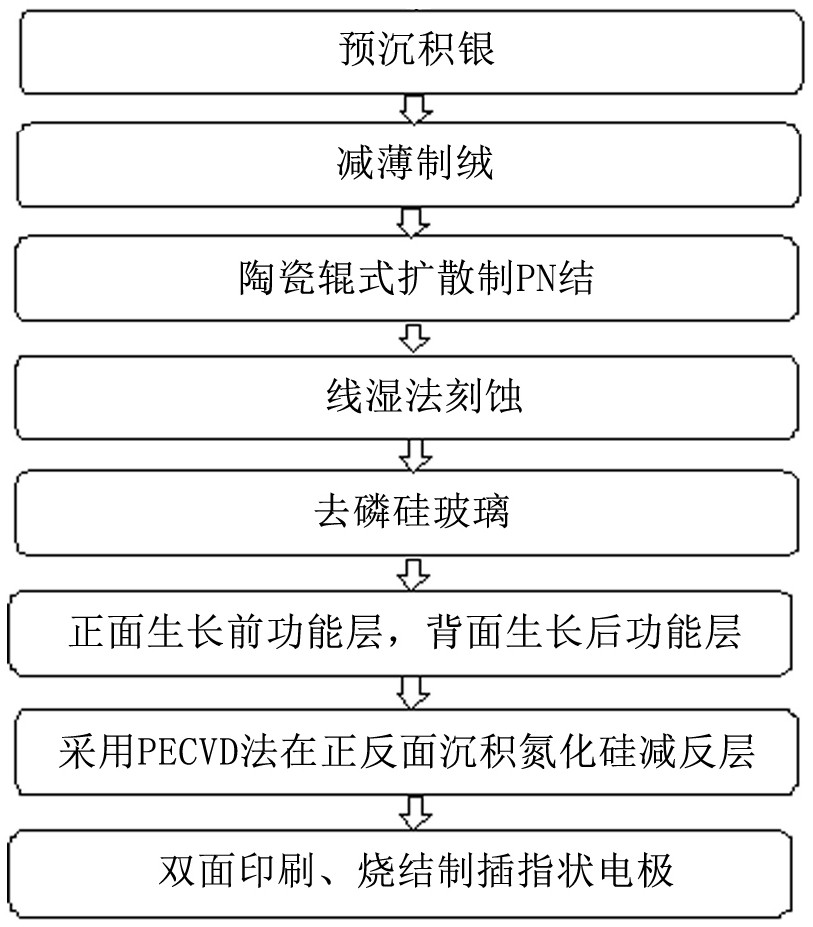

Method for preparing ultrathin crystalline silicon double-sided solar cell

ActiveCN109802009AImprove light energy utilizationIncrease light dwell timeFinal product manufacturePhotovoltaic energy generationPhosphoric acidSilicon nitride

The invention provides a method for preparing ultrathin crystalline silicon double-sided solar cell. The method comprises steps of: firstly thinning a polycrystalline silicon substrate to 90-120[mu]mat 18-25 degrees centigrade for 2000-2300s by using a mixed solution of HF, H2O2 and an additive, wherein a textured structure is formed on the surface of the substrate during the thinning process; preparing a PN junction by roll diffusion, and using ultrasonic atomization of phosphoric acid, thereby being nontoxic and nonpolluting, and achieving a uniform diffusion junction; and disposing siliconnitride antireflection layers on the front and back sides of the substrate; finally forming finger electrodes on the front and back sides by a silk-screen printing and sintering process. The method is suitable for the production technology of polycrystalline silicon 90-120[mu]m thick. Compared with a method for preparing a conventional polycrystalline silicon cell 180[mu]m thick, the method can reduce the thickness of the cell under the premise of ensuring a fragmentation rate, ensures battery efficiency, is simple in process, and low in cost. The method also solves the problem that the thincell is likely to be bent and is fragile, and can be industrialized by experimental verification.

Owner:HEBEI UNIVERSITY

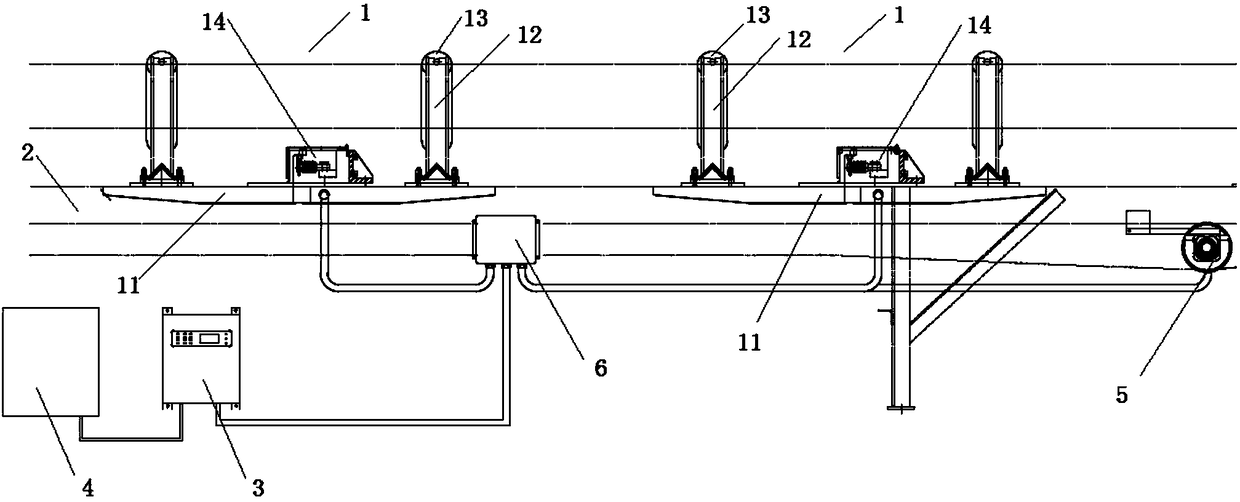

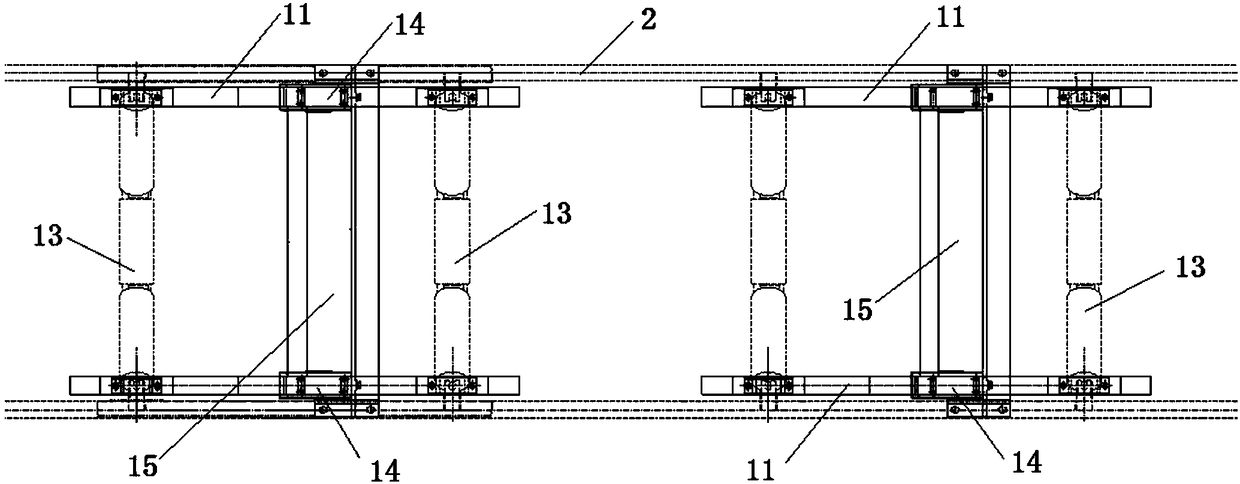

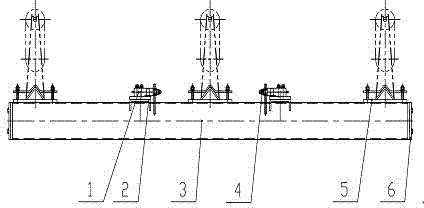

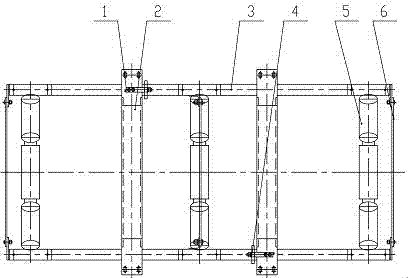

High-precision suspension array belt metering scale

InactiveCN108151836ARelieve structural internal stressSimple structureWeighing apparatus for continuous material flowIntegratorEngineering

The invention relates to a high-precision suspension array belt metering scale, which comprises a plurality of groups of full-suspension scale groups uniformly distributed on a rack of a belt conveyor. Each full-suspension scale group comprises two weighing bridges arranged on the rack on the two sides and a plurality of weighing carrier roller supports are arranged on each weighing bridge. Weighing carrier rollers are arranged on the weighing carrier roller supports, and a bearing beam is arranged between two weighing bridges. Two weighing sensors are arranged on the bearing beam. All the weighing sensors are connected to an integrator. A speed measuring device arranged below the rack is connected with the integrator. The integrator is further connected with an industrial controller. According to the invention, a weighing bridge frame is connected with the weighing sensors in a freely floating mode, while no inhibiting device is arranged. Fewer force transmission links are arranged, and the high-precision suspension array belt metering scale is accurate and reliable in weight measurement and high in measurement accuracy. The high-precision suspension array belt metering scale hasthe advantages of strong load-deflection resistance performance, large bandwidth for adapted belt conveyors, high belt speed and the like. Meanwhile, the weighing bridge frame is simple in structure,convenient to install and free of maintenance. The high-precision suspension array belt metering scale serves as optimal equipment for the measurement of high-precision belt conveyors.

Owner:徐州格雷安环保设备有限公司

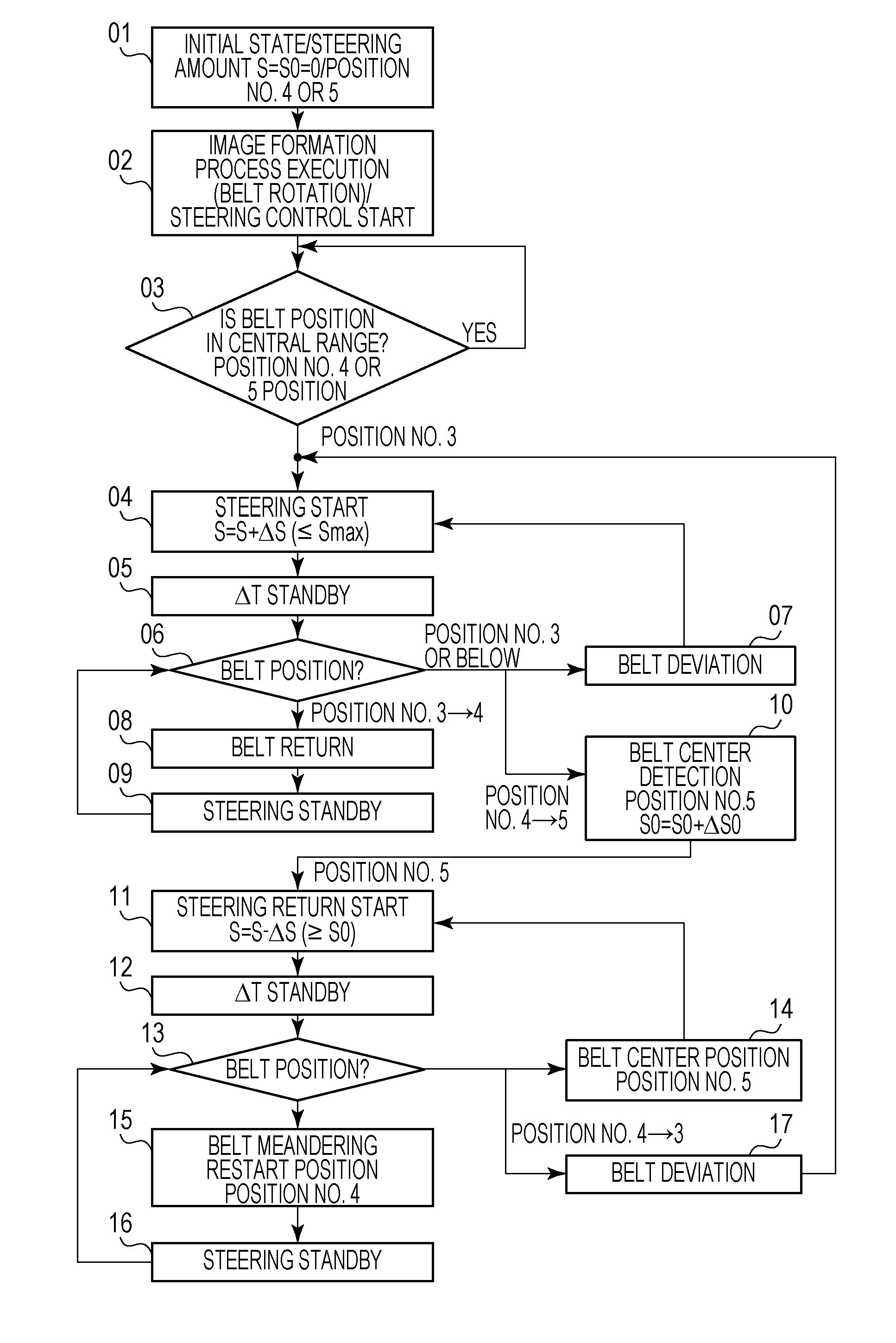

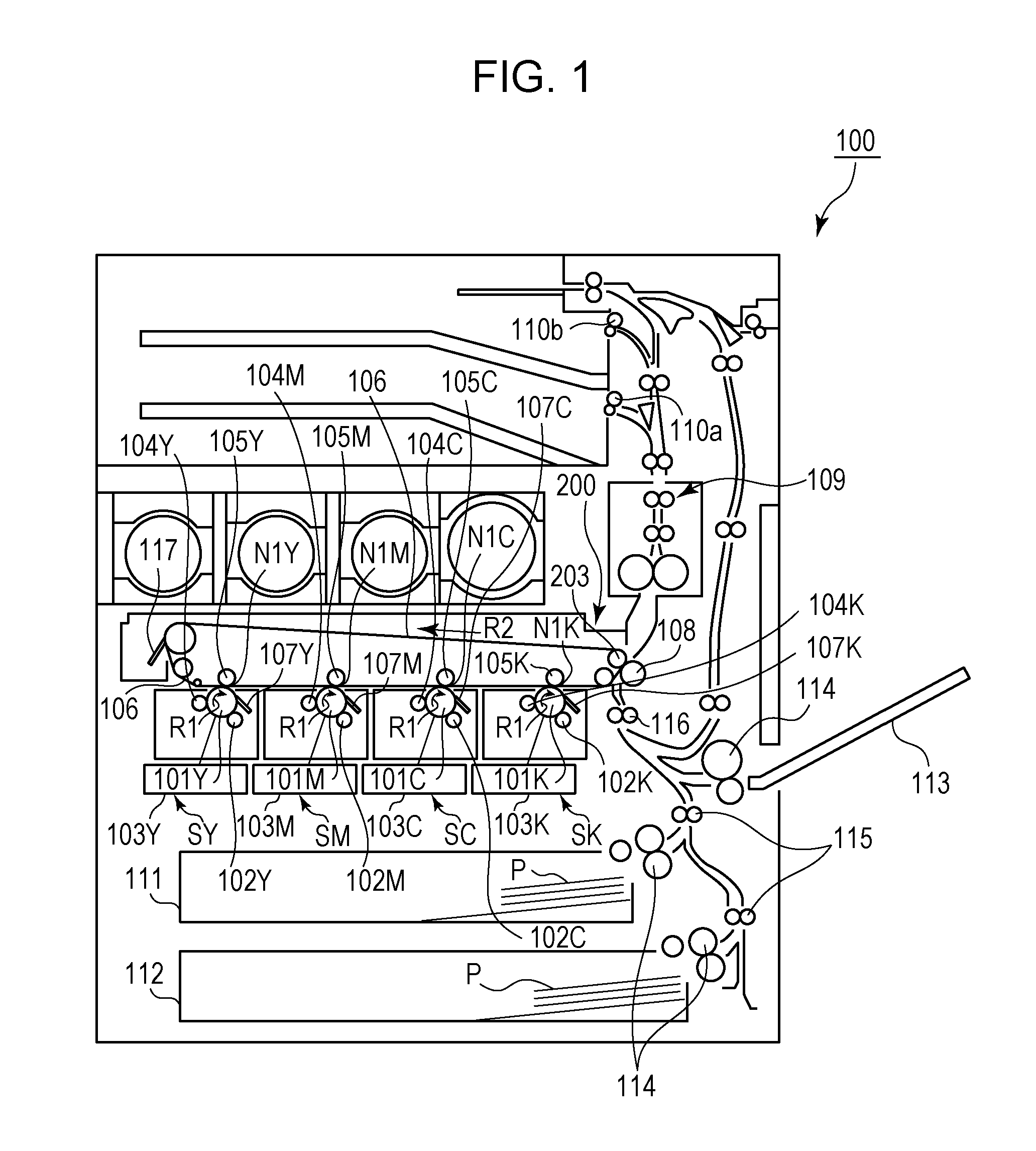

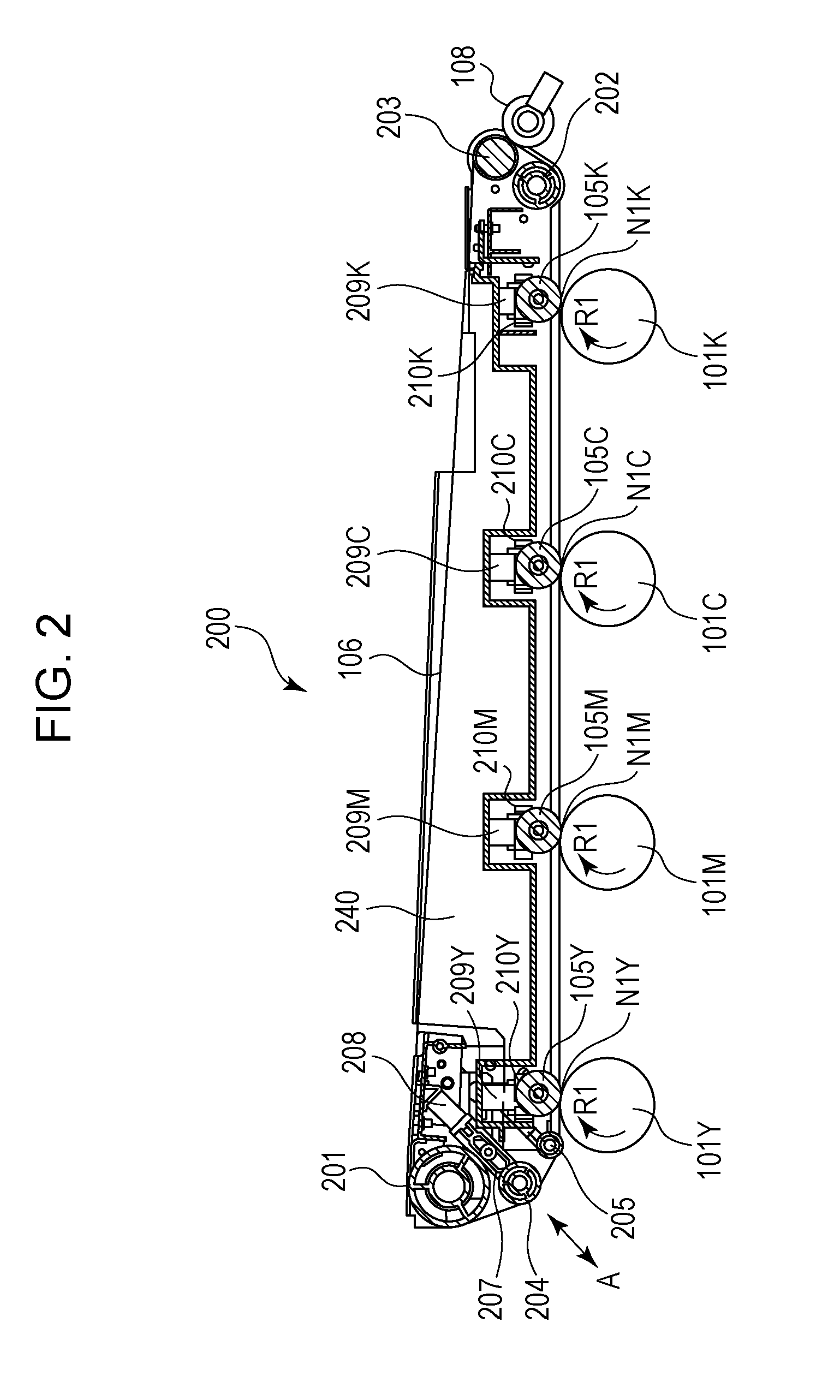

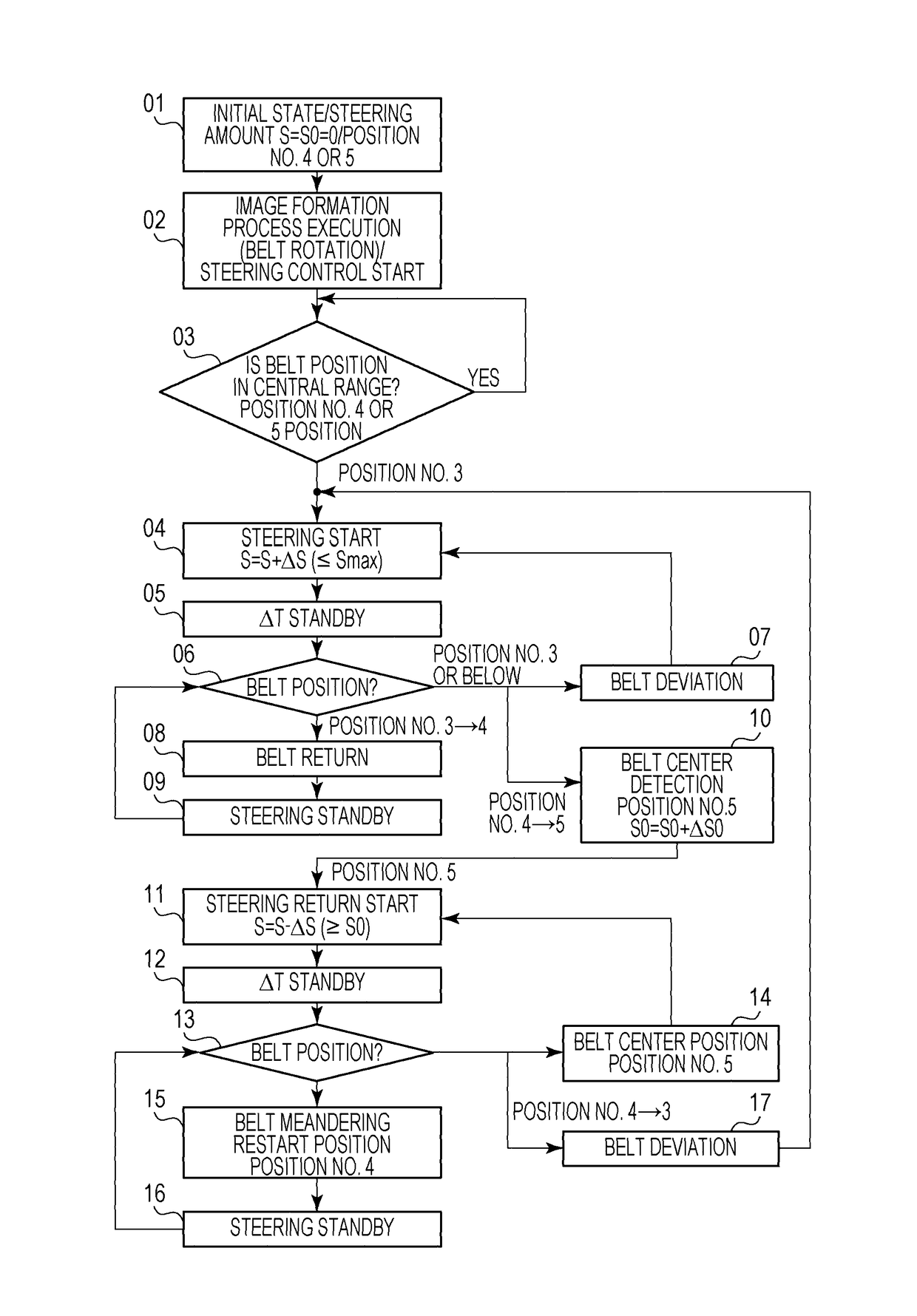

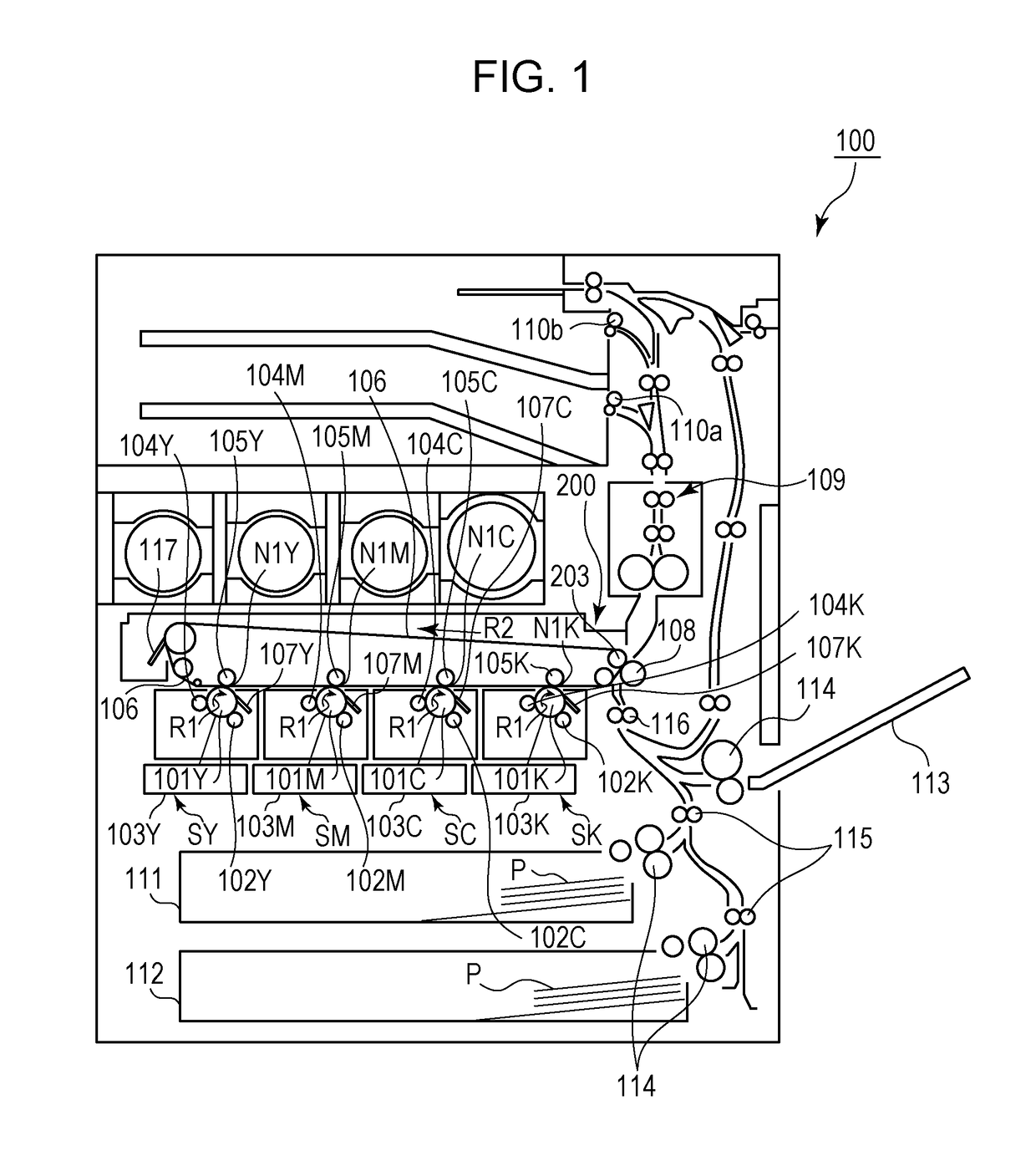

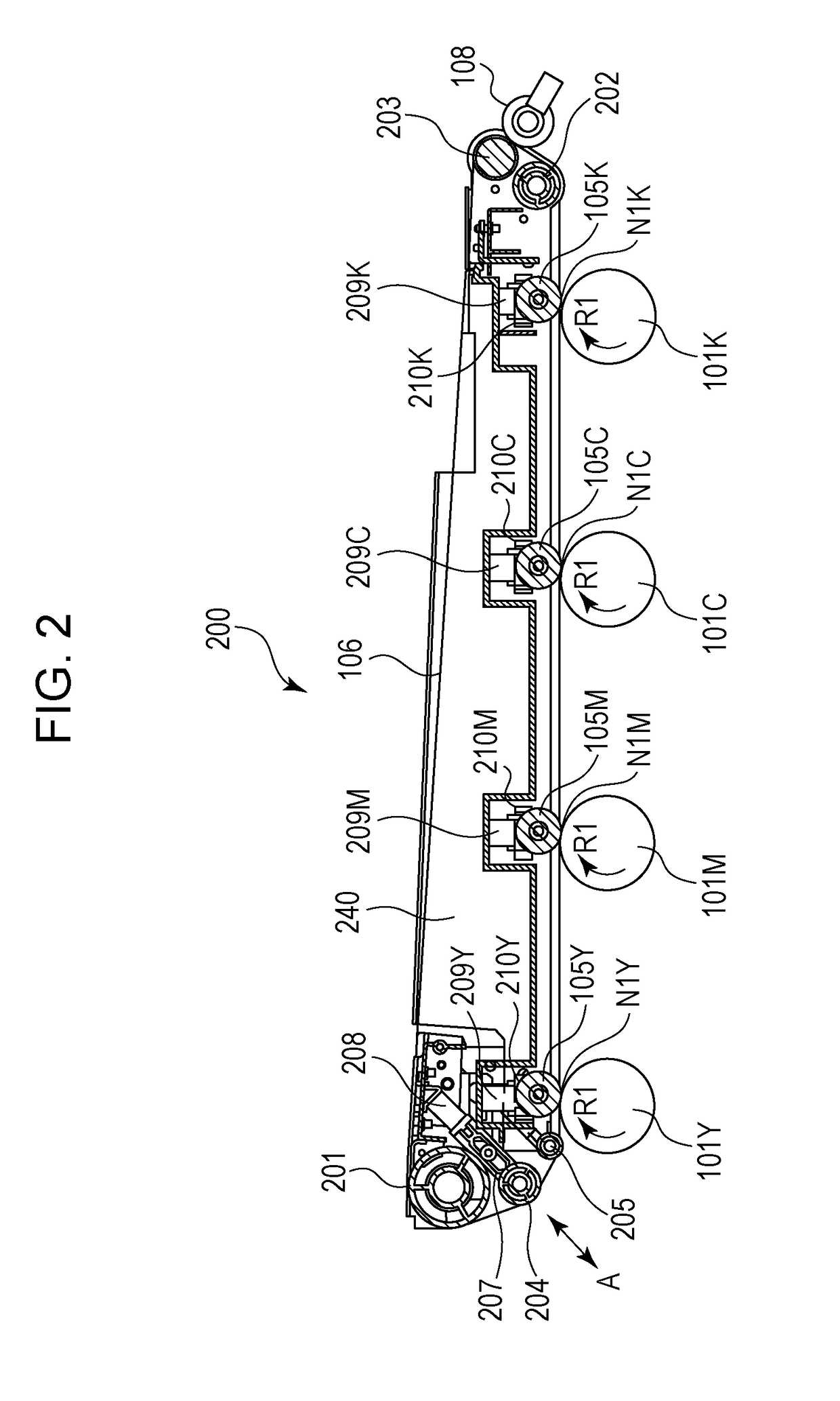

Belt conveying device and image forming apparatus

ActiveUS20170060044A1Reducing transitional changeHigh belt speedElectrographic process apparatusEngineeringMechanical engineering

A belt conveying device is configured such that if belt deviation in which a belt moves in a direction separated from a predetermined position is detected by a belt position detection mechanism, a control unit controls a driving unit to make a steering roller to be tilted intermittently in a direction to correct the belt deviation and, if it is detected by the belt position detection mechanism that a moving direction of the belt has changed to a direction to approach the predetermined position in a suspension period between the intermittent tilting operation, suspends the subsequent tilting of the steering roller.

Owner:CANON KK

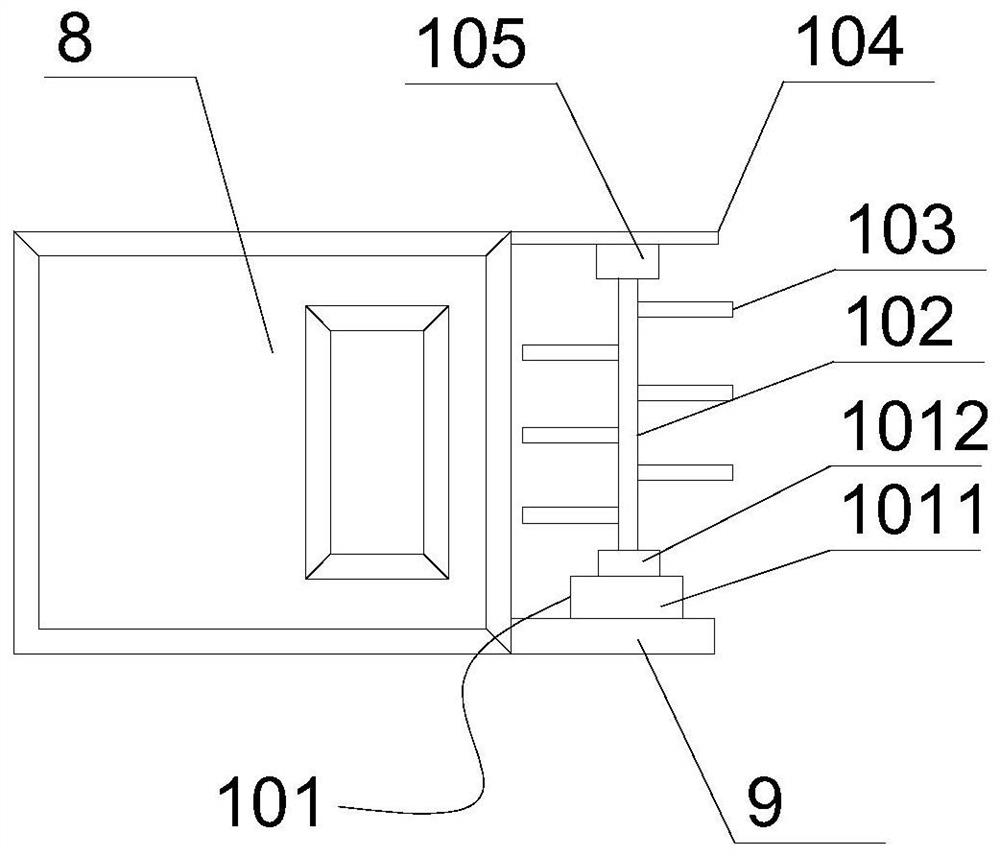

Device and method for recognizing and sorting sundries in coal conveying process

PendingCN114101081AReduce conveying speedIncrease delivery speedSortingDust controlStructural engineering

The invention relates to the technical field of coal transportation equipment, in particular to a device and method for recognizing and sorting sundries in the coal conveying process. Comprising a first belt conveyor, a second belt conveyor, a material distribution module, a camera recognition module, a six-axis robot, a truss robot, a dust removal pipeline, a lead protective cover, an X-ray source box and a sorting box, the first belt conveyor is in lap joint with the second belt conveyor, and the material distribution module is fixedly connected with the first belt conveyor; the camera recognition module is fixedly connected with the first belt conveyor and located on one side of the material distribution module, the six-axis robot and the truss robot are fixedly connected with the first belt conveyor and located above the first belt conveyor, and the lead protective cover, the X-ray source box and the sorting box are fixedly connected with the second belt conveyor and located above the second belt conveyor. And the dust removal pipeline penetrates through the sorting box, and through the arrangement of the structure, multi-mode identification and multi-means sorting of coal flow are achieved.

Owner:CHINA COAL SCI & TECH GRP NANJING DESIGN & RES INST CO LTD +1

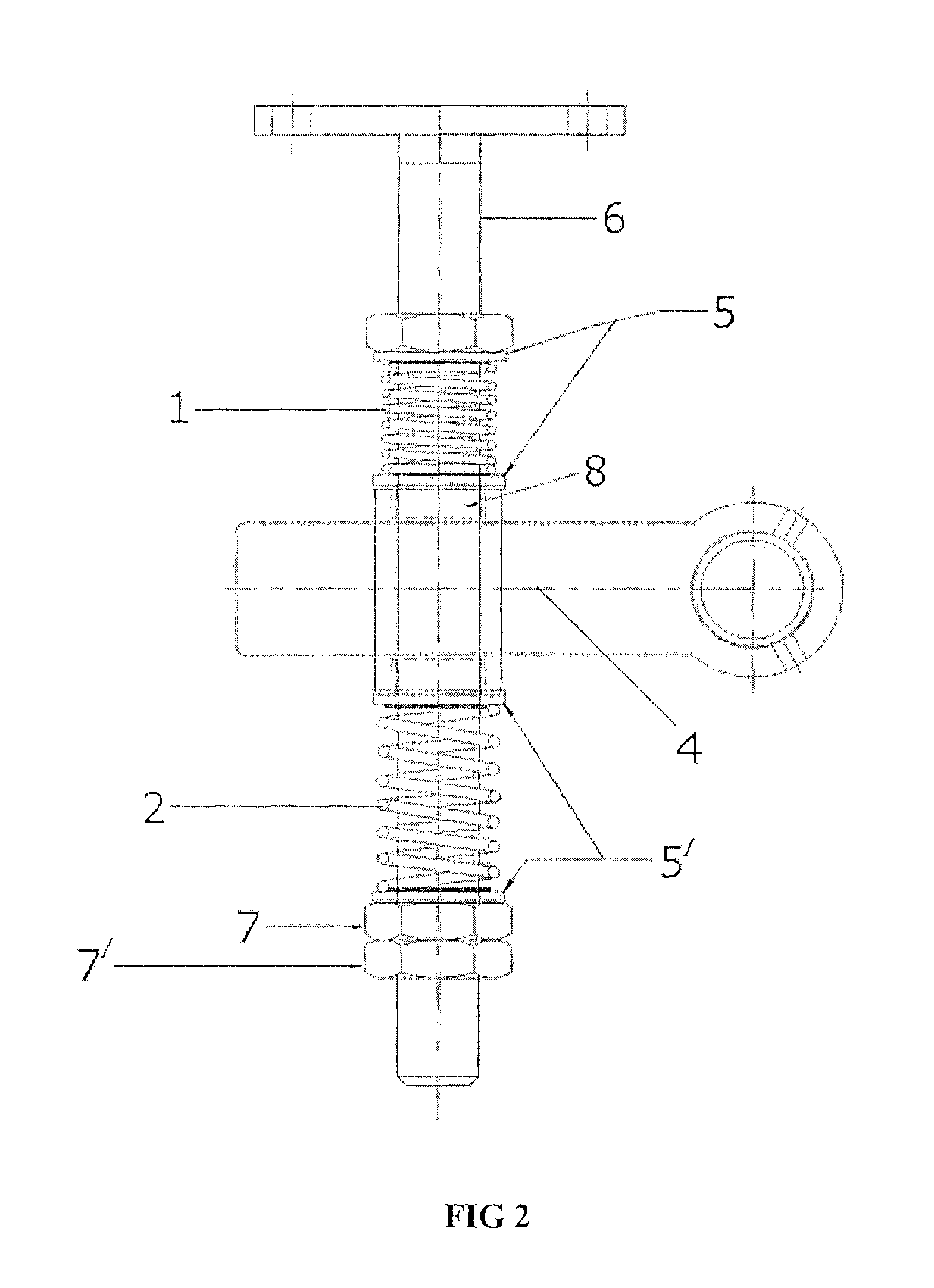

Belt scraper mounting

A belt scraper mounting for belt conveyors with a conveyor frame / stringer includes a scraper blade module assembly and a scraper fixing mount. The scraper fixing mount holds the blade module assembly with the conveyor frame / stringer on both sides of the scraper blade module assembly and functions in an auto adjusting mode.

Owner:TEGA IND LTD

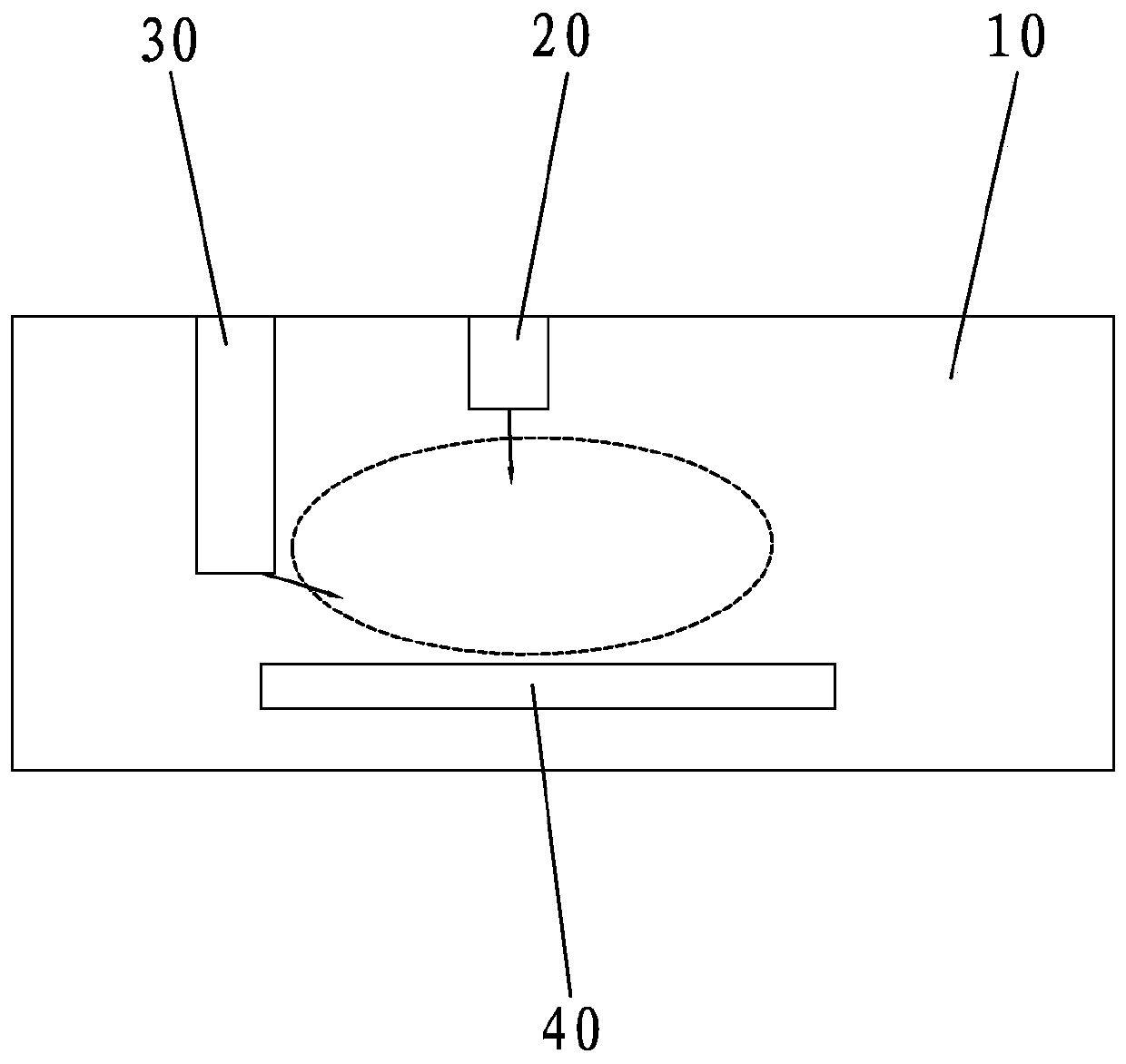

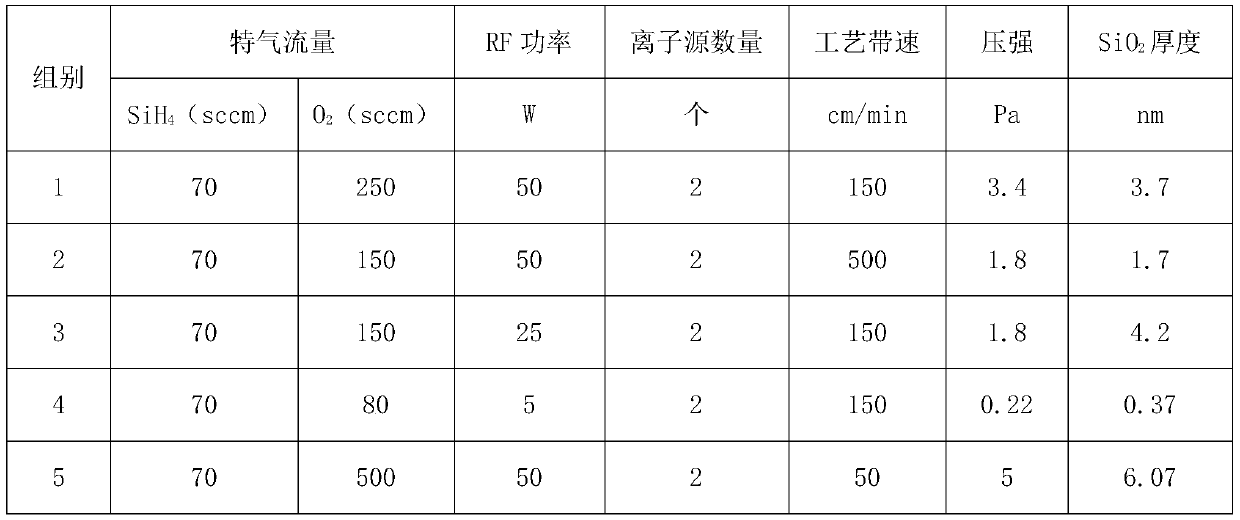

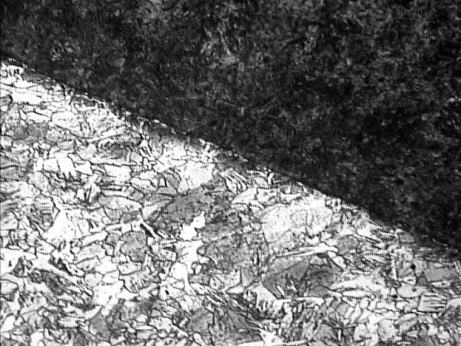

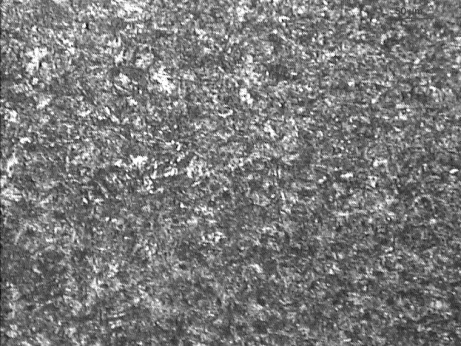

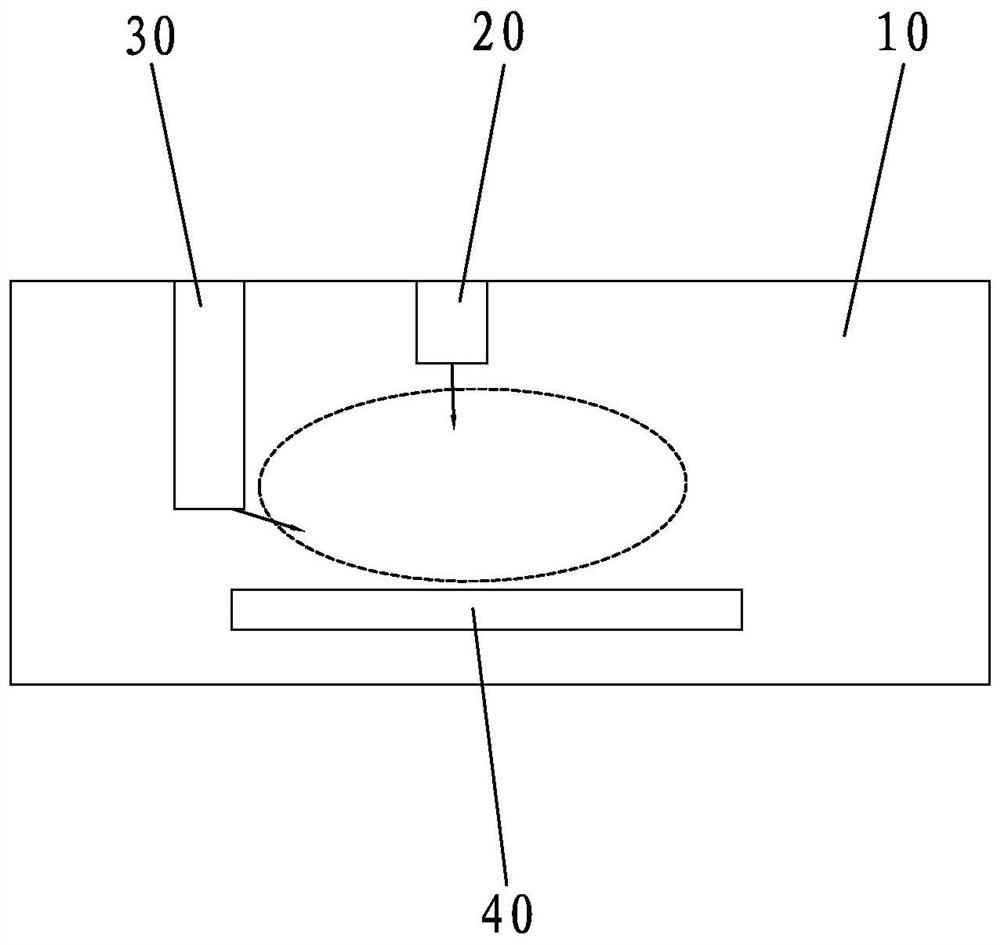

Preparation method of thin-layer SiO2 passivation film and prepared battery

ActiveCN110952073ALow process temperatureHigh belt speedFinal product manufactureChemical vapor deposition coatingPhysicsSilicon chip

The invention discloses a preparation method of a thin-layer SiO2 passivation film. The method specifically comprises the following steps that 1) firstly, a chain type continuous coating PECVD deviceis provided; 2) carrier plates carrying silicon wafers are continuously conveyed into a process cavity of the chain type PECVD device through a continuous conveying mechanism to realize coating; (3) in the process cavity, a gas outlet hole of an electrode plate of a plasma source is used for discharging O2, meanwhile, SiH4 is discharged from a gas distribution block on the side face of the electrode plate of the plasma source, the SiH4 and the O2 enter into different areas of the process cavity through different pipelines and flow out to encounter and mix with each other under vacuum of 1-20 Pa and form SiO2 passivation films on the surfaces of the continuously conveyed silicon wafers. According to the method, only the two specific gases SiH4 and O2 are used as reaction gases, a separatedgas inlet mode is used, so that the method has the advantages of low process temperature, safety, reliability, environmental protection and the like, dynamic chain type continuous coating and growingare achieved, the belt speed is high, the yield is large and uniformity is highly controllable.

Owner:江苏杰太光电技术有限公司

Welding method for high-carbon-equivalent strip steel in continuous annealing

PendingCN112958930AAvoid the risk of broken strapsGuaranteed smooth productionFurnace typesWelding apparatusProduction rateEconomic benefits

The invention discloses a welding method for high-carbon-equivalent strip steel in continuous annealing. In a continuous annealing process for strip steel, a plurality of steel coils are connected end to end and welded together, then continuous annealing is carried out, and every two adjacent welded steel coils are different in carbon equivalent and comprise the high-carbon-equivalent strip steel and the low-carbon-equivalent strip steel. According to the invention, the problem that the high-carbon-equivalent strip steel is difficult to weld during the continuous annealing can be effectively solved, the risk that the strip steel is broken due to cracking in a welding seam structure is avoided, and the stability of the welding quality is improved; and the production smoothness of the strip steel is ensured, the strip speed of the continuous annealing for a target steel grade is increased, the stability of a furnace area process is improved, the full-coil stability of products is optimized, the production rate of enterprises is increased, and the economic benefits of the enterprises are improved.

Owner:HANDAN IRON & STEEL GROUP +1

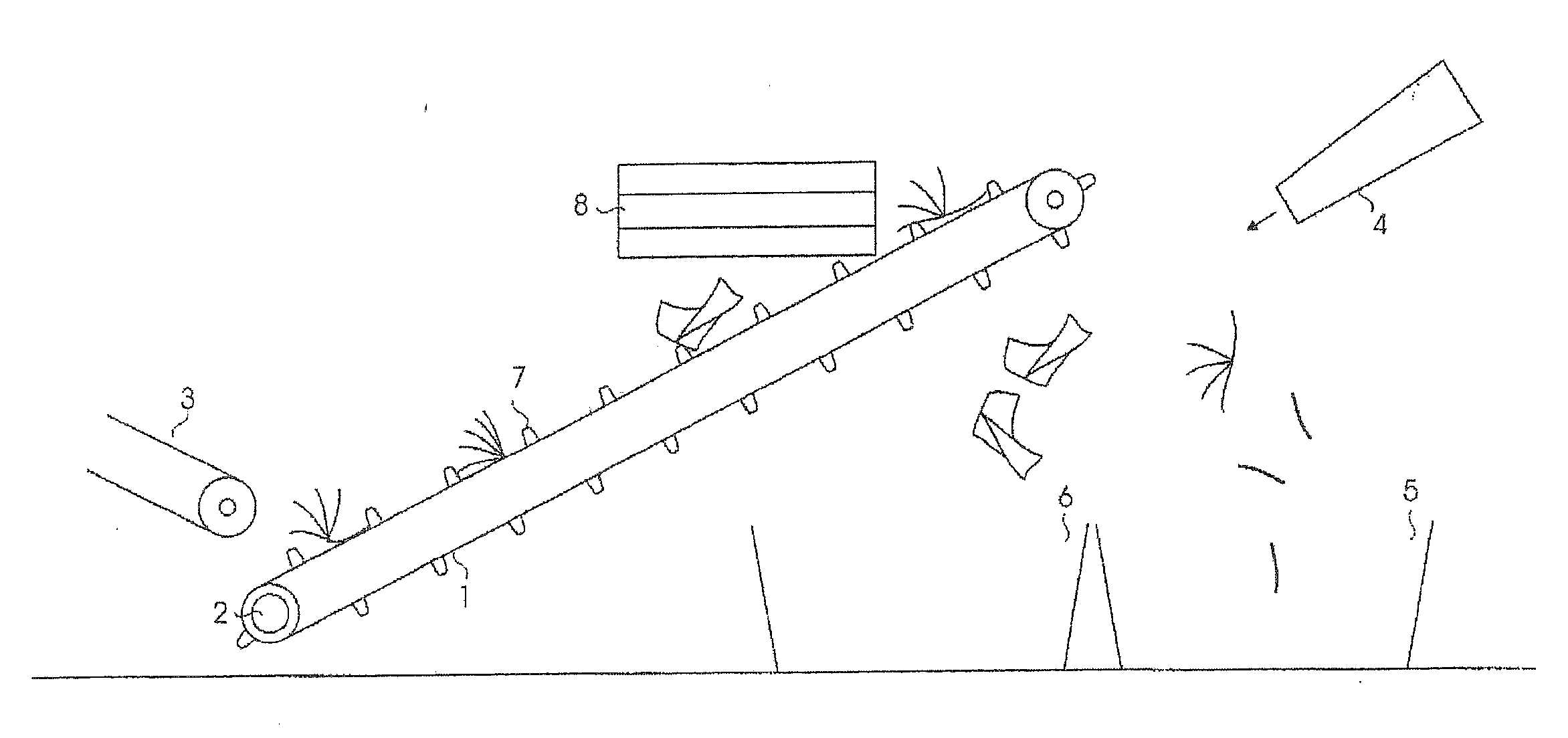

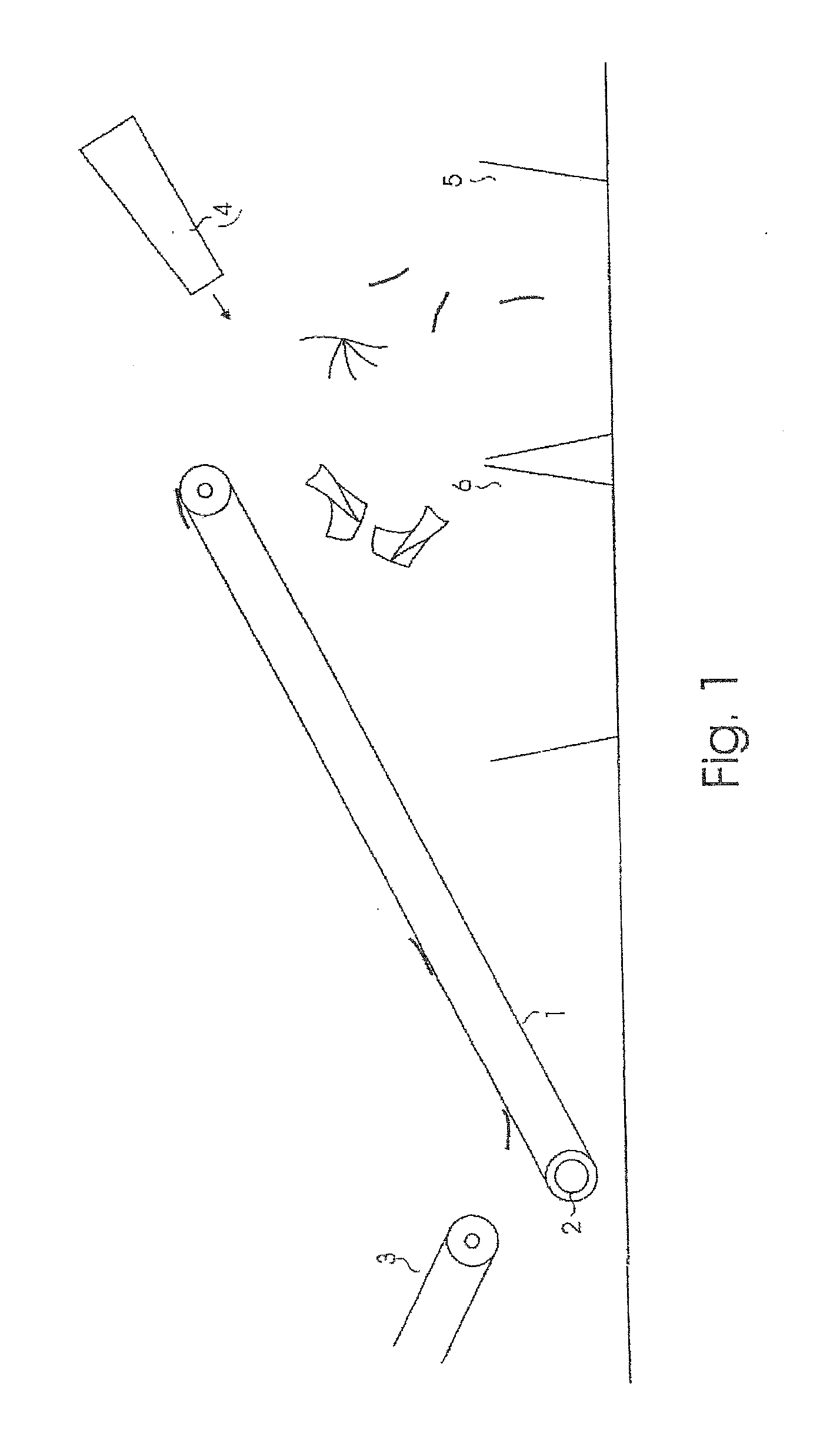

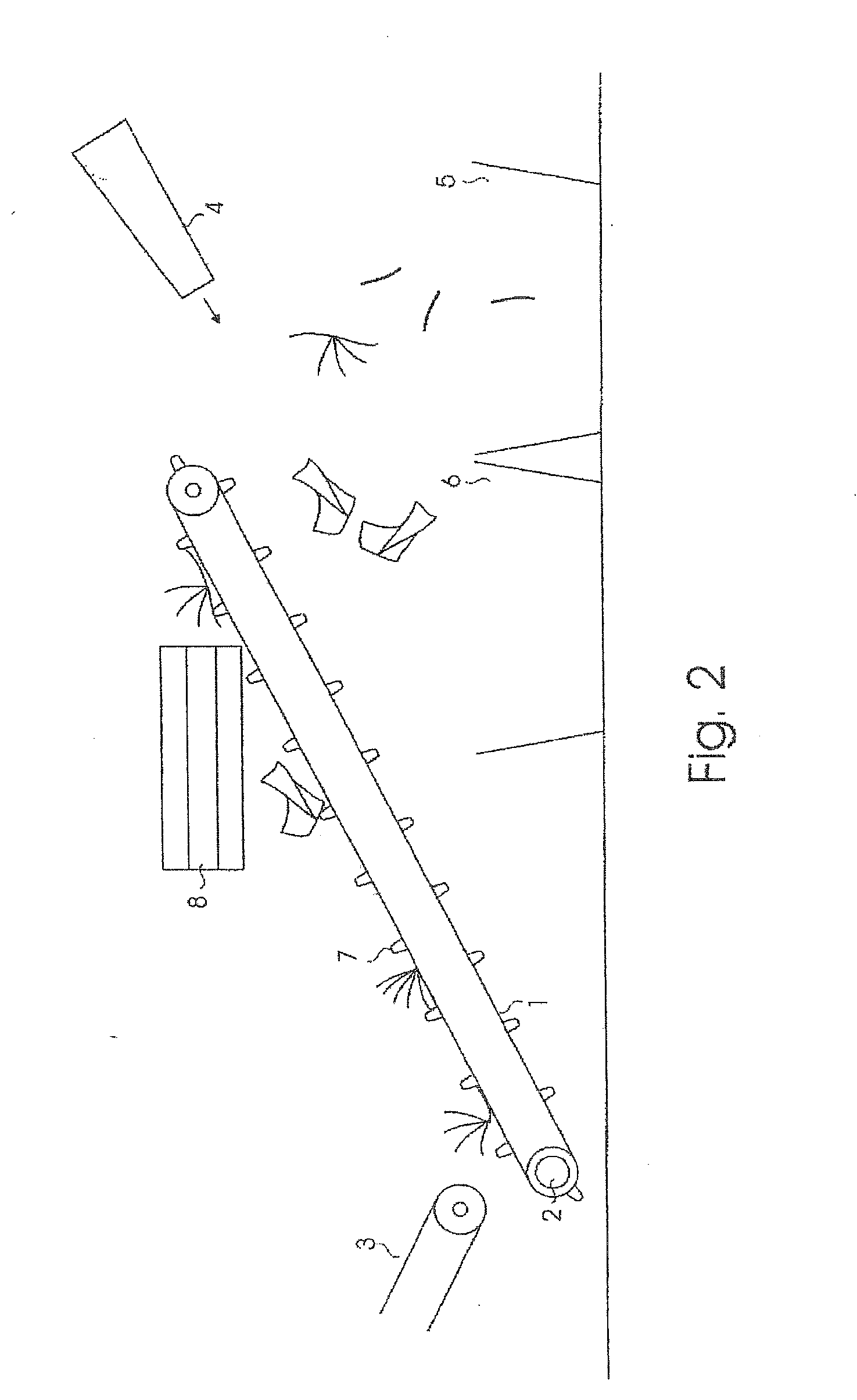

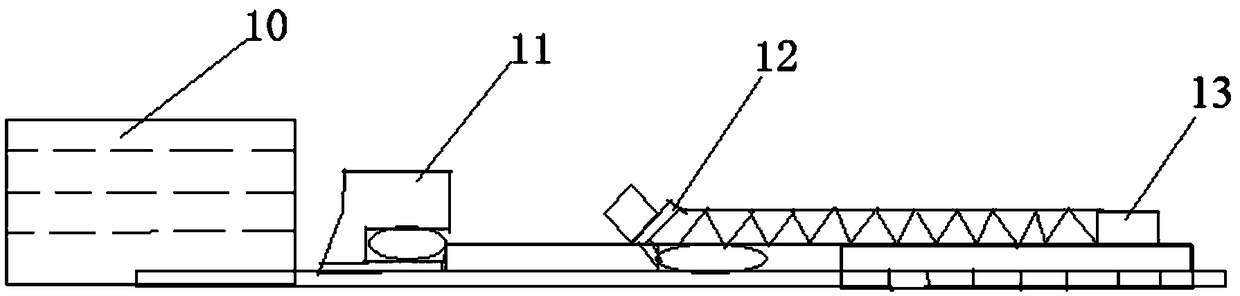

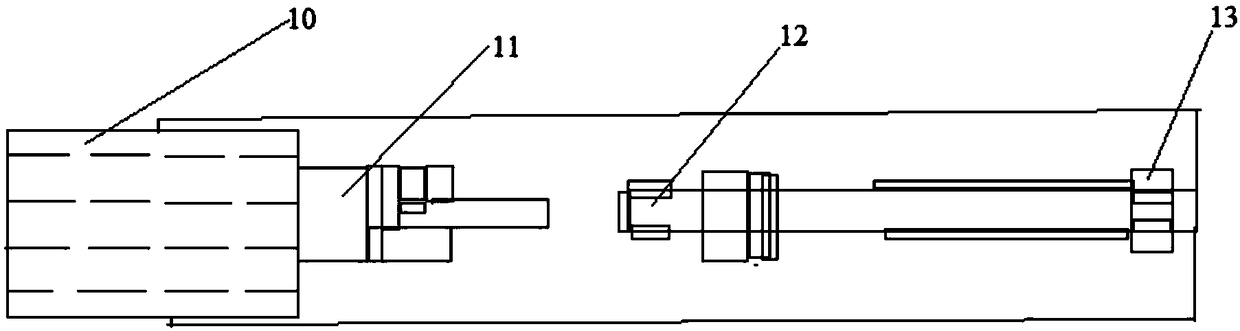

Structure and working method for the sorting of waste products

InactiveUS20110186482A1Increase surface areaImprove shipping speedGas current separationSortingPressure systemWaste product

An apparatus for the separation of waste paper includes a slanted conveyor belt with a lower end and an upper end, the upper end being positioned at a height above the lower end, the conveyor belt traveling from the lower end to the upper end. A plurality of drive mechanisms drive the slanted conveyor belt. At least one load mechanism supplies the waste paper at the lower end of the conveyor belt. At least one air pressure system is positioned adjacent to the upper end of the conveyor belt. The plurality of drive mechanisms provide a minimum speed of 3 meters per second.

Owner:ORIG

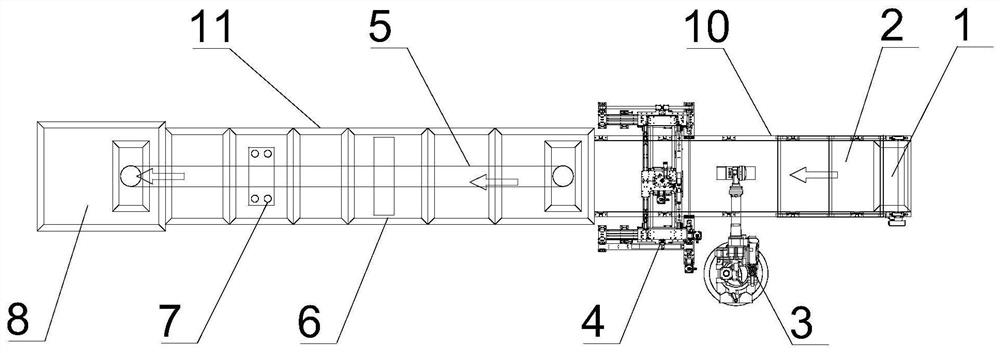

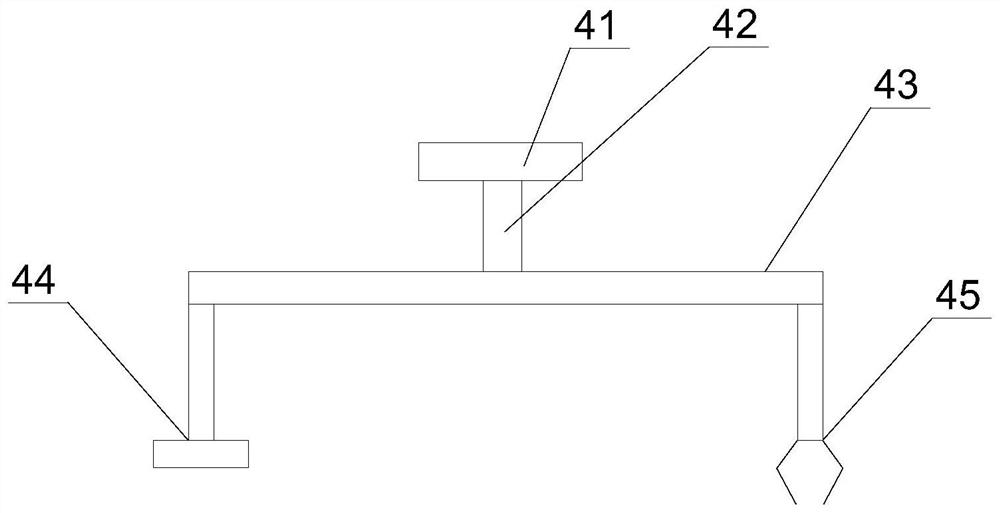

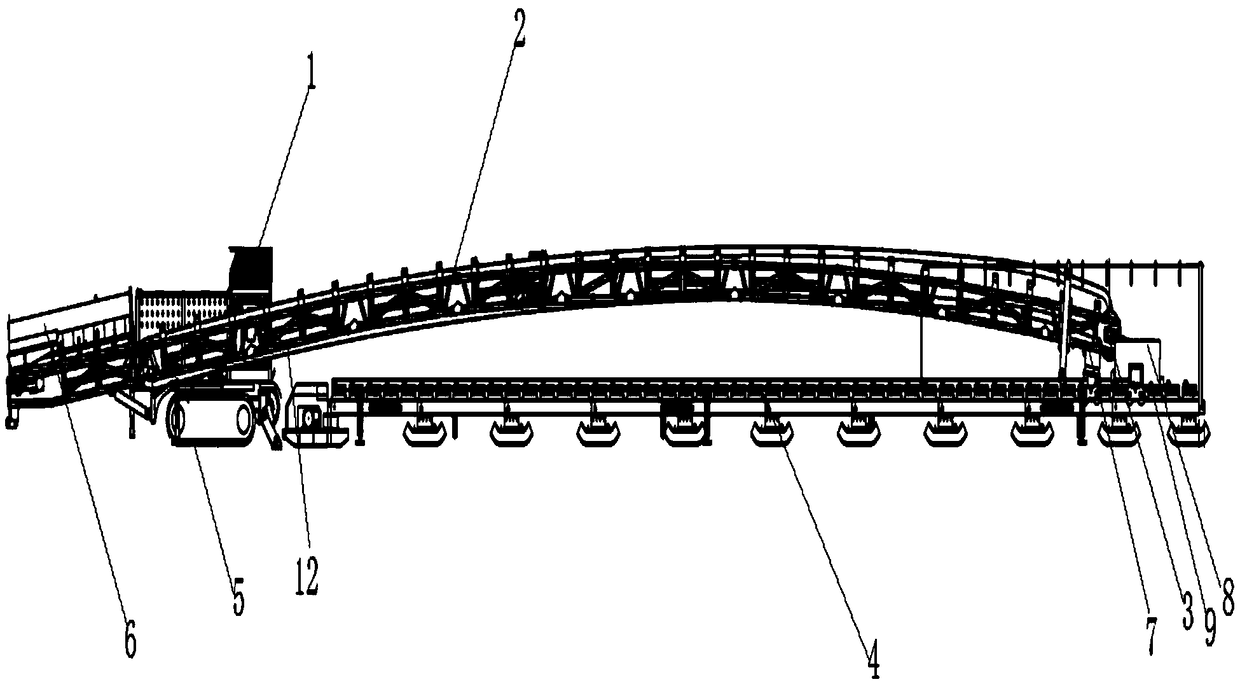

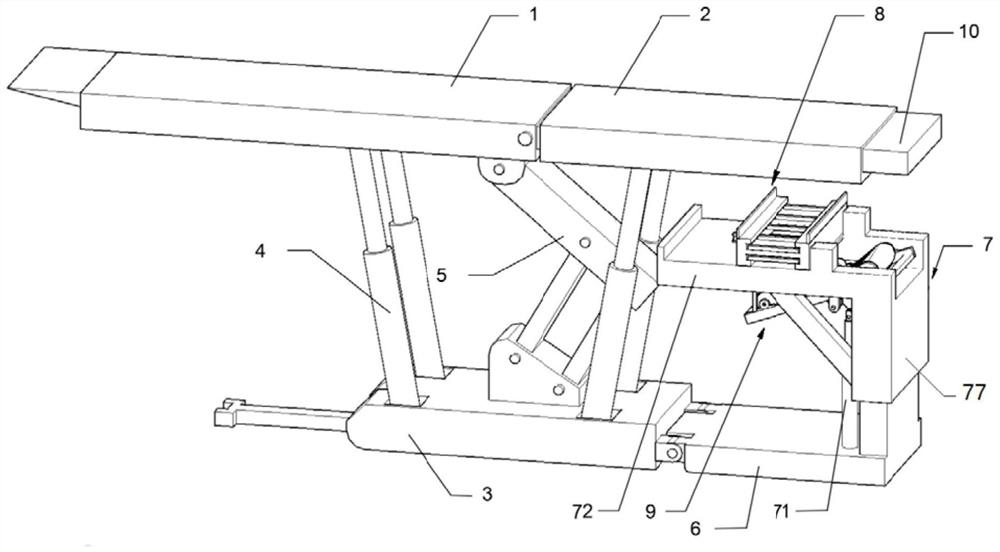

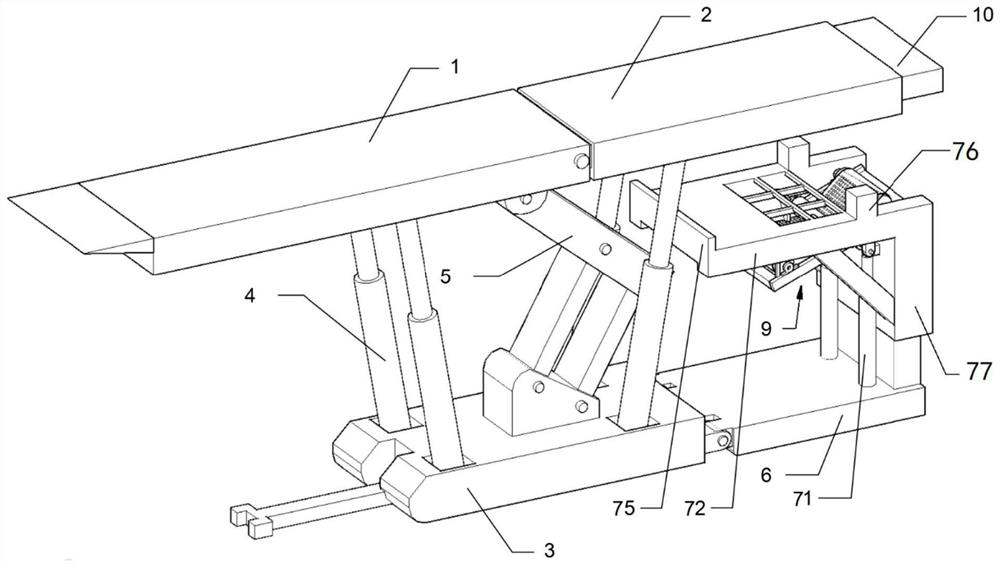

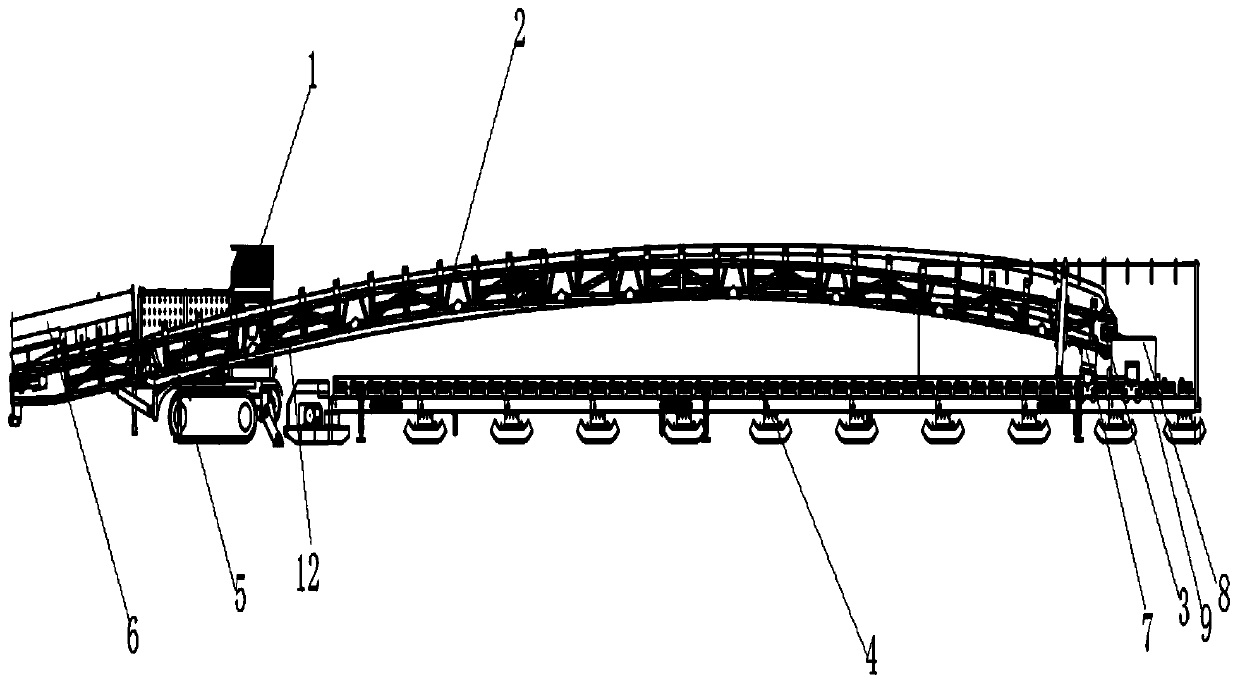

Self-walking two-conveying transfer machine for coal mine

ActiveCN108868764AHas a self-contained dynamic approachMeet the self-contained dynamic approachSlitting machinesEngineeringMechanical engineering

The invention discloses a self-walking two-conveying transfer machine for coal mine which comprises a power waling part, a two-conveying transfer part, an extension machine tail and an extension coalreceiving funnel; the power waling part is directly connected with the two-conveying transfer part; the extension machine tail is provided with a slideway; the extension coal receiving funnel is arranged on the extension machine tail; and the extension machine tail is directly connected with the two-conveying transfer part to be used for transferring coals on the two-conveying transfer part. The self-walking two-conveying transfer machine provided by the invention solves the problems of high cost and low efficiency of the existing coal mine roadway excavation.

Owner:SHAANXI COAL IND GRP SHENNAN IND DEV CO LTD

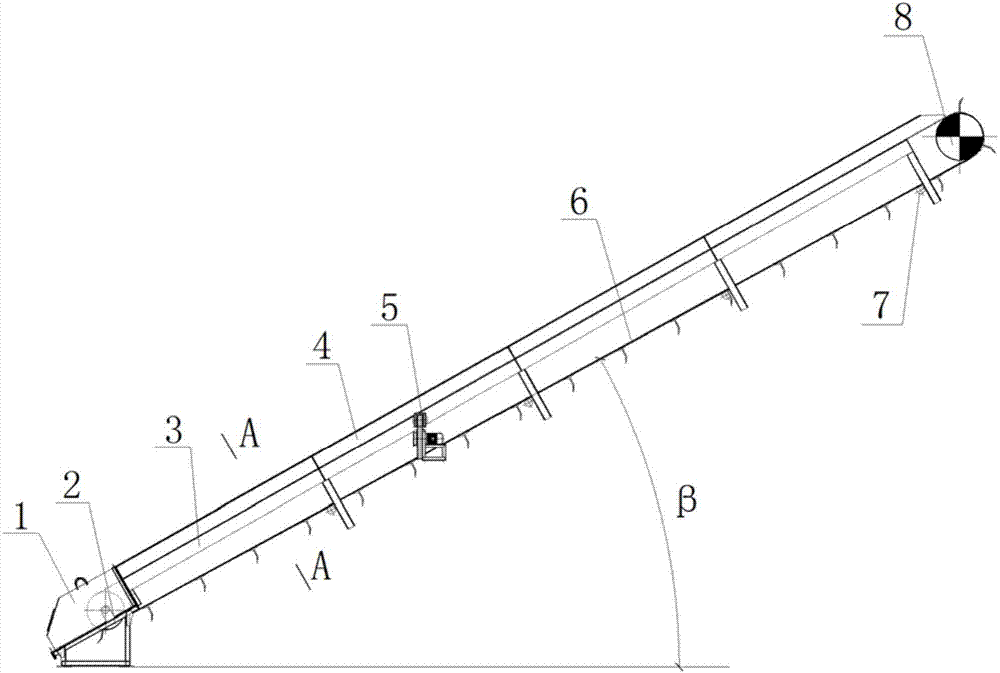

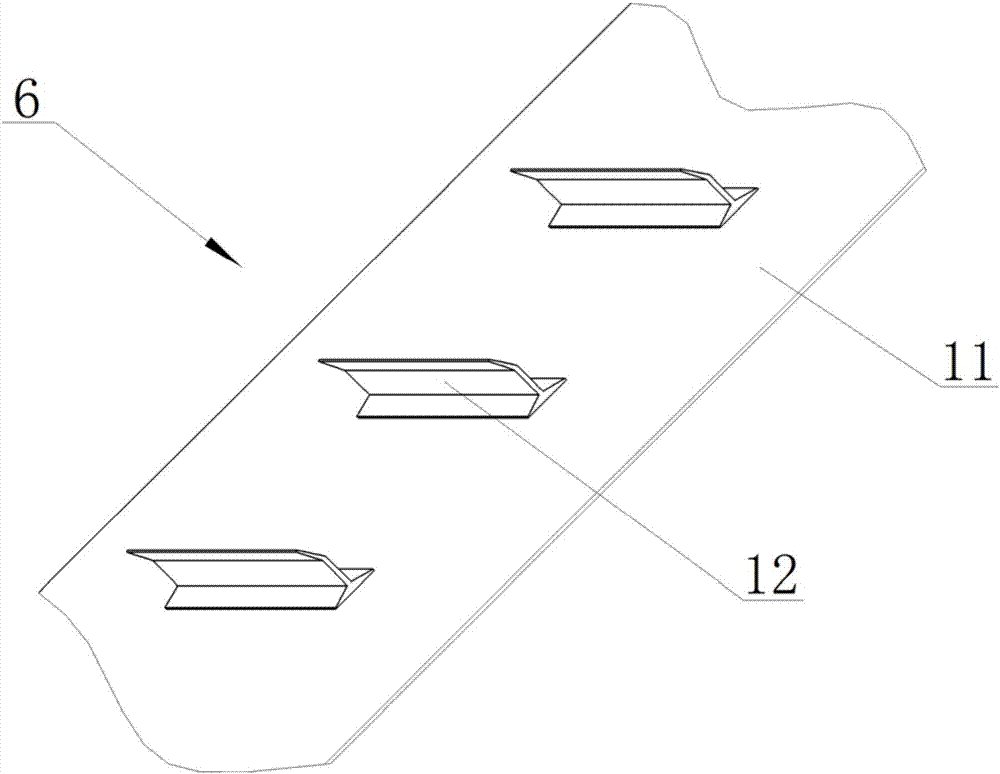

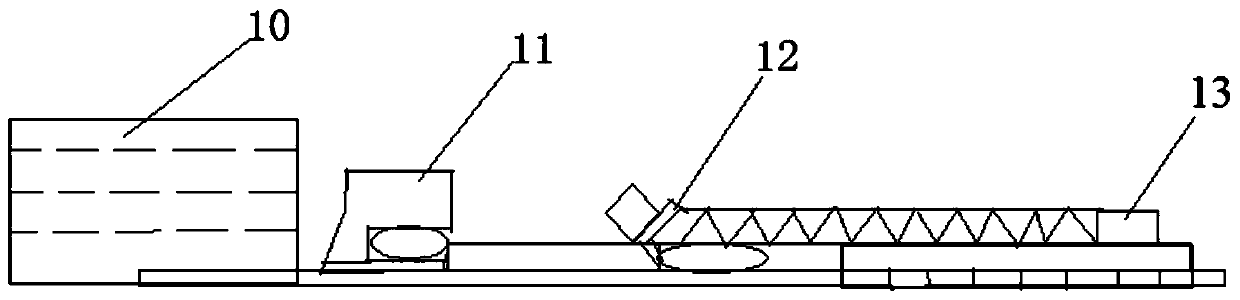

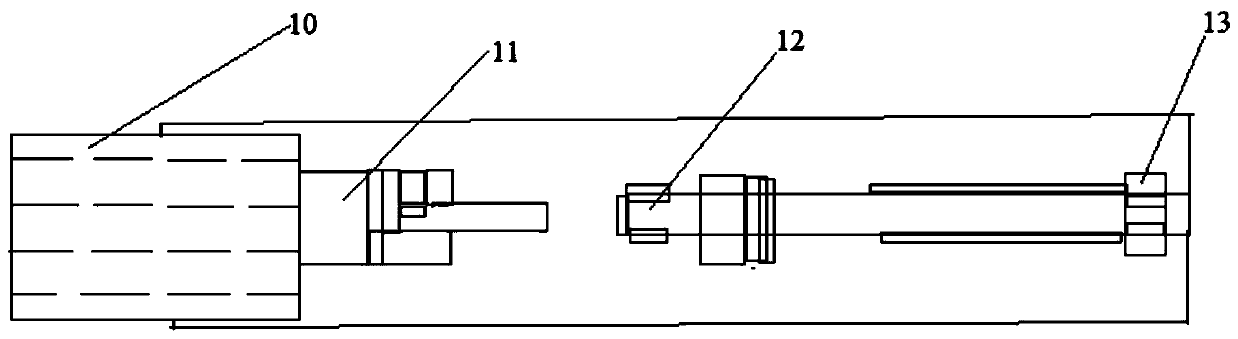

Large-angle packaged object air cushion conveyer

PendingCN107244524AReduce wearThe overall structure is simple and reliableConveyorsMechanical wearBelt speed

The invention relates to a large-angle packaged object air cushion conveyer which comprises a partition plate conveying belt (6). The partition plate conveying belt (6) comprises a basic belt (11) and multiple middle partition plates (12), and the width of each middle partition plate (12) is smaller than that of the basic belt (11). Compared with the prior art, the large-angle packaged object air cushion conveyer has the technical beneficial effects of being simple and reliable in structure, high in belt speed, stable in operation, free of jolting and rolling off, high in conveying efficiency and large in climbing angle. By means of a pressure air film generated by an air chamber arranged on a tilt lifting section, the partition plate conveying belt and packaged objects on the partition plate conveying belt are jacked up, the partition plate conveying belt operates under drive of a head transmission roller, and therefore the technical effect of large-tilt-angle conveying of the packaged objects is achieved. Due to the fact that an air cushion is adopted for the work of conveying the packaged objects, equipment energy consumption is obviously reduced, meanwhile, mechanical wear is small, and damage is not prone to happening; and the use cost is low, energy saving and environment protection are achieved, and the large-angle packaged object air cushion conveyer is suitable for large-tilt-angle conveying work of packaged objects in all industries.

Owner:SUZHOU NIUKU CONVEYING MACHINERY CO LTD

Belt conveying device and image forming apparatus having steering control mechanism

ActiveUS10031447B2Reduce changesHigh belt speedElectrographic process apparatusEngineeringSteering control

A belt conveying device is configured such that if belt deviation in which a belt moves in a direction separated from a predetermined position is detected by a belt position detection mechanism, a control unit controls a driving unit to make a steering roller to be tilted intermittently in a direction to correct the belt deviation and, if it is detected by the belt position detection mechanism that a moving direction of the belt has changed to a direction to approach the predetermined position in a suspension period between the intermittent tilting operation, suspends the subsequent tilting of the steering roller.

Owner:CANON KK

Fully-mechanized coal mining supporting and throwing type gangue filling hydraulic support

PendingCN113685214AImprove filling efficiencyImprove fill rateMaterial fill-upMine roof supportsThermodynamicsIndustrial engineering

The invention provides a fully-mechanized coal mining supporting and throwing type gangue filling hydraulic support. The installation mode of a bottom unloading scraper conveyor on the rear portion of a traditional fully-mechanized coal mining gangue filling hydraulic support is changed into a bearing mode from a hanging mode, the degree of freedom of the scraper conveyor on a bearing platform is greatly increased, chain ring connection between the scraper conveyor and the hydraulic support is avoided, and the hydraulic support is not affected by the width of a working face; and meanwhile, the width of a fully-mechanized coal mining gangue filling working face is increased, the structure and the size of a gangue throwing belt conveyor are optimized, the gangue filling efficiency and the filling roof contact rate are improved, the frame tail filling empty roof distance is reduced, and the gangue throwing inclination, the gangue throwing speed, the gangue throwing height and the gangue throwing distance are improved.

Owner:中煤能源研究院有限责任公司

A belt type dry magnetic separator

ActiveCN106000636BEasy to handleHigh belt speedMagnetic separationProcess equipmentMagnetic separator

The invention discloses a belt-type dry magnetic separator. The belt-type dry magnetic separator comprises a housing, the upper part of the housing is provided with a feeding inlet, a feeding device is arranged below the feeding inlet, a magnetic separation device is arranged above the feeding device, the magnetic separation device comprises a magnetic separation belt, along a material conveying direction of the feeding device, a primary separation magnetic system and a refined separation magnetic system are orderly arranged in the magnetic separation belt in parallel, a conveying tail end of the feeding device is not in a magnetic material discharge range of the refined separation magnetic system, a magnetic field range of the primary separation magnetic system covers materials on the feeding device, a magnetic field of the refined separation magnetic system is an alternating magnetic field, and magnetic field ranges of the primary separation magnetic system and the refined separation magnetic system are superimposed. The belt-type dry magnetic separator continuously treats a crushed magnetic material so that a product with quality close to that of water separated products is obtained, strictly controls mine tailing magnetic object quality, has a high treatment capability and a large tailings discarding rate, has a very wide mineral particle fraction application range and reduces a later technical equipment investment and a system operation cost.

Owner:CHENGDU LEEJUN TECH CO LTD

Preparation method of crystalline silicon solar cell

ActiveCN102244143BHigh belt speedControl thicknessFinal product manufactureChemical vapor deposition coatingDiffusionBuilding integration

The invention discloses a preparation method of a crystalline silicon solar cell. The method comprises the following steps: 1, carrying out texture etching and diffusion on a raw material silicon wafer, wherein the depth of texture etching is controlled to be 0.2-1.0 mu m, the diffusion is controlled to be 0.1-0.2 mu m; 2, coating a silicon nitride antireflection film by using PECVD (plasma enhanced chemical vapor deposition) equipment, wherein the flow ratio of ammonia gas NH3 and silane SIH4 entering into the first four U-shaped grooves of the PECVD equipment is 6:5; the flow ratio of ammonia gas NH3 and silane SIH4 entering into the last four U-shaped grooves of the PECVD equipment is 3:1-4:1; hydrogen H2 with gas flow of 200-300Sccm is charged in the five U-shaped groove in all the U-shaped grooves; the color of the film of which the thickness is controlled to be 20-40nm is yellow, the color of the film of which the thickness is controlled to be 40-60nm is red, and the color of the film of which the thickness is controlled to be 100-120nm is green. According to the invention, through changing the total amount of the gas entering all the U-shaped grooves of the PECVD equipment,the thickness of the antireflection film can be controlled, and then the cell can show red, green and yellow, so that the demand for the integration of photovoltaic products and buildings can be satisfied. The invention has the advantages of increasing output, reducing the flows of ammonia gas NH3, silane SIH4 and hydrogen H2, improving production efficiency and lowering the cost.

Owner:BAODING GUANGWEI GREEN ENERGY TECH CO LTD

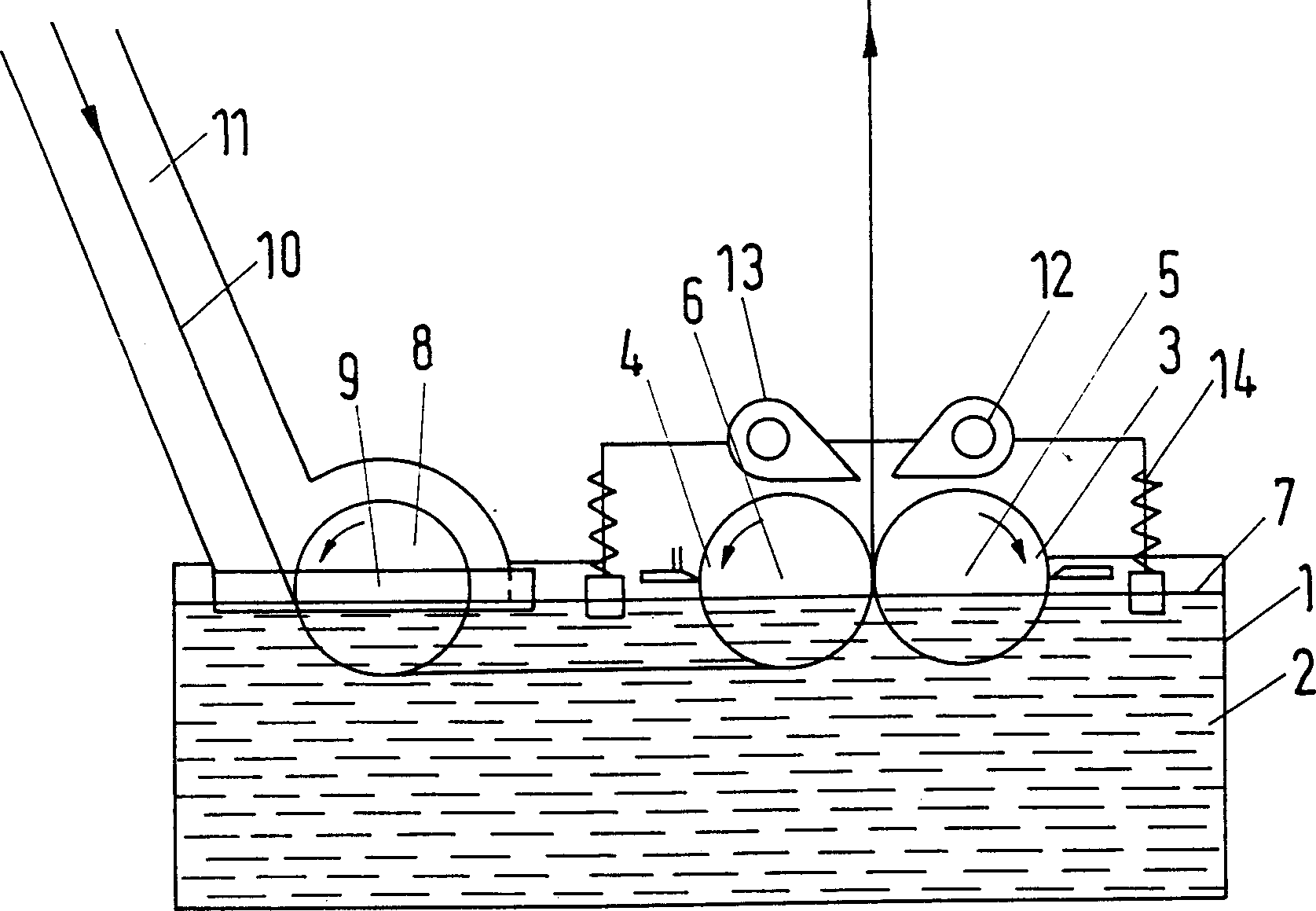

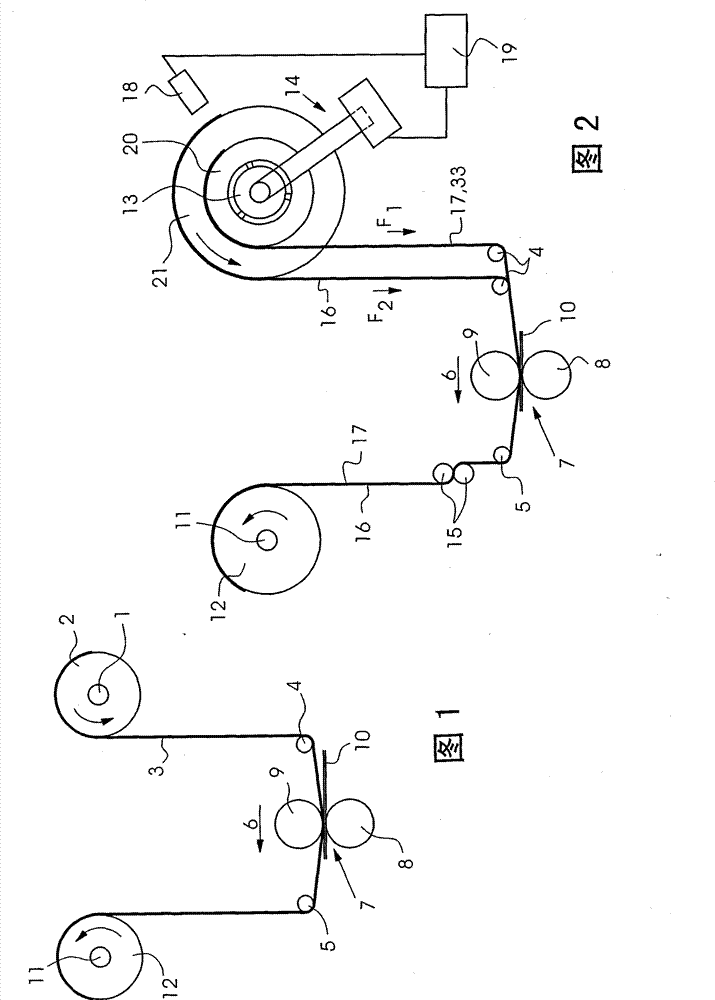

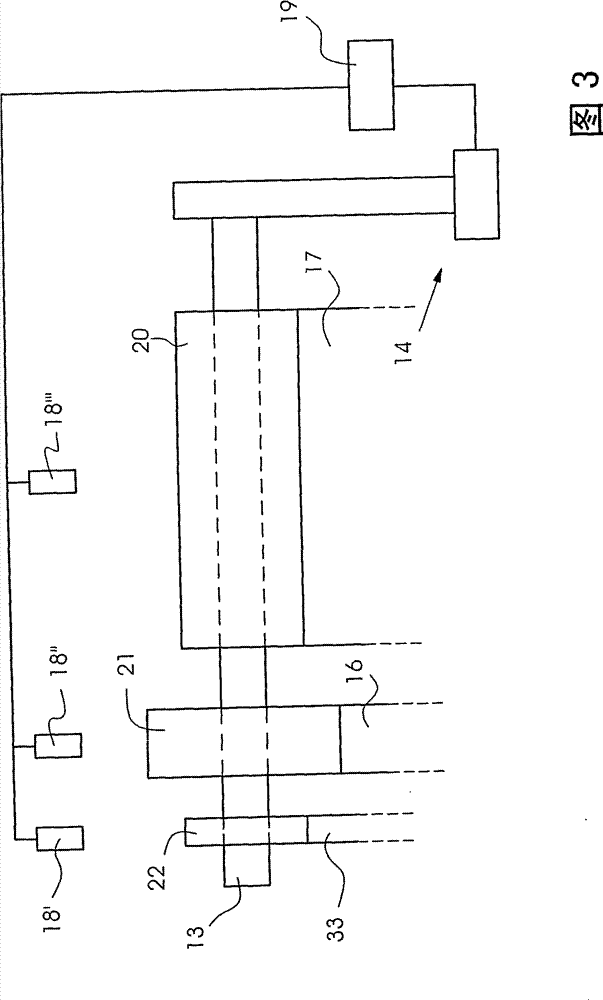

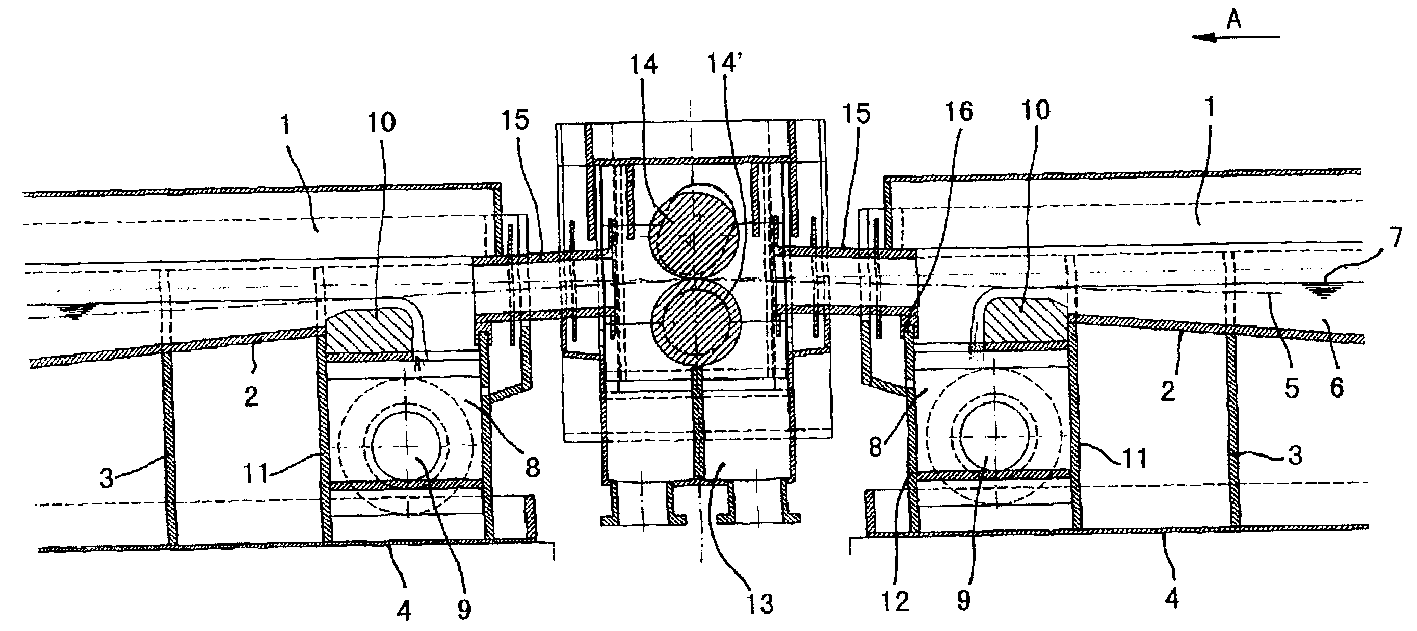

Coating apparatus

InactiveCN1134309CShort soaking cycleService life advantageHot-dipping/immersion processesLiquid surface applicatorsBand shapeMetallurgy

A coating plant for coating strip-shaped material with covering material, in which the strip-shaped material which is to be coated is guided into a coating bath, and is guided between two coating rolls, which are partly immersed in the coating bath, out of the coating bath and past stripping nozzles, the bearings of the coating rolls being arranged outside of the coating bath. Preferably the strip-shaped material is guided into the coating bath by means of one or more deflector rolls of which at least one is arranged outside of the coating bath.

Owner:方丹工程机械有限公司

Free float type belt weighing device

ActiveCN102818608BEasy to installSimple structureWeighing apparatus detailsWeighing apparatus for continuous material flowUniversal jointEngineering

Owner:SAIMO ELECTRIC +1

A self-propelled two-wheel loader for coal mines

ActiveCN108868764BHas a self-contained dynamic approachMeet the self-contained dynamic approachSlitting machinesMining engineeringProcess engineering

The invention discloses a self-walking two-conveying transfer machine for coal mine which comprises a power waling part, a two-conveying transfer part, an extension machine tail and an extension coalreceiving funnel; the power waling part is directly connected with the two-conveying transfer part; the extension machine tail is provided with a slideway; the extension coal receiving funnel is arranged on the extension machine tail; and the extension machine tail is directly connected with the two-conveying transfer part to be used for transferring coals on the two-conveying transfer part. The self-walking two-conveying transfer machine provided by the invention solves the problems of high cost and low efficiency of the existing coal mine roadway excavation.

Owner:SHAANXI COAL IND GRP SHENNAN IND DEV CO LTD

a thin layer sio 2 Preparation method of passivation film and prepared battery

ActiveCN110952073BLow process temperatureHigh belt speedFinal product manufactureChemical vapor deposition coatingElectrical batteryThin layer

The invention discloses a thin-layer SiO 2 The preparation method of the passivation film specifically includes the following steps: 1) firstly provide a PECVD equipment for chain continuous coating; 2) continuously transport the carrier plate loaded with silicon wafers into the process chamber of the chain PECVD equipment through a continuous conveying mechanism Realize coating; 3) In the process chamber, through the electrode plate air outlet of the plasma source, the 0 2 At the same time, SiH is released from the gas distribution block on the side of the electrode plate of the plasma source 4 , SiH 4 and O 2 The two gases enter different areas of the process chamber through different pipelines and flow out, meet and mix under a vacuum of 1-20Pa and form SiO on the surface of the continuously transported silicon wafer 2 passivation film. The invention only needs to use two kinds of special gas SiH 4 and O 2 As a reaction gas, and using a separate air intake method, it has the advantages of low process temperature, safety, reliability and environmental protection, and the dynamic chain continuous coating growth, high belt speed, large output, and highly controllable uniformity.

Owner:江苏杰太光电技术有限公司

Film transfering mechanism with integrated continuously processing device

ActiveCN101045361BTransfers are precise and cleanImprove beatTransfer printingPattern printingMechanical engineeringPhysics

Owner:海德堡印刷机械知识产权股份两合公司

Method for manufacturing silicon solar cell

InactiveCN101783374BReduce sheet resistanceLower ohmic contactFinal product manufactureSemiconductor devicesElectrical resistance and conductanceOhmic contact

The invention discloses a method for manufacturing a silicon solar cell. In the process of manufacturing a PN junction on a silicon wafer, a selective diffusion technology method is adopted, i,e. laser is utilized to heat a position, on which a positive electrode intends to be manufactured, on the surface of the silicon wafer; and under the action of heating, phosphorus in a phosphorus source uniformly adhered on the surface diffuses towards the inner of the silicon wafer, thus a heavy doping zone with smaller sheet resistance is formed at the position on which the positive electrode intends to be manufactured to effectively reduce the sheet resistance of the silicon solar cell, thereby not only being beneficial for increasing the open-circuit voltage of the silicon solar cell; the increase of the open-circuit voltage effectively improves the conversion efficiency of the silicon solar cell, reduces ohmic contact of a metal electrode and the silicon solar cell, thereby reducing the series resistance of the silicon solar cell, and being capable of meeting the demand of industrialized production better.

Owner:SUN EARTH SOLAR POWER

Wire rod cooling device

PendingCN112011753AHigh belt speedImprove cooling efficiencyHot-dipping/immersion processesWire rodCooling fluid

The invention relates to a wire rod cooling device. The wire rod cooling device comprises a cooling cylinder and an inner pipe, wherein the cooling cylinder is provided with an inner cavity, the innercavity is used for loading cooling liquid, and a wire inlet and a wire outlet are formed in the lower end and the upper end of the cooling cylinder correspondingly; and the periphery of the upper endof the inner pipe is connected to the periphery of the wire outlet in a sealed mode, a wire passing channel is formed in the inner pipe, and the lower end of the inner pipe extends towards the wire inlet; and an extraction opening is further formed in the cooling cylinder and communicates an the inner cavity between the outer wall of the inner pipe and the inner wall of the cooling cylinder. Thebelt speed of a wire rod can be increased.

Owner:昆山奥特莱机电科技有限公司

Continuous processing system for steel strip

A continuous steel strip treatment unit, having squeeze rolls (14, 14') located in separate containers (13) at treatment vessel ends, is new.

Owner:ANDRITZ PATENTVERW GES

A kind of preparation method of ultra-thin crystalline silicon double-sided solar cell

ActiveCN109802009BThin securityFast thinningFinal product manufacturePhotovoltaic energy generationPhosphoric acidSolar battery

The invention provides a method for preparing ultrathin crystalline silicon double-sided solar cell. The method comprises steps of: firstly thinning a polycrystalline silicon substrate to 90-120[mu]mat 18-25 degrees centigrade for 2000-2300s by using a mixed solution of HF, H2O2 and an additive, wherein a textured structure is formed on the surface of the substrate during the thinning process; preparing a PN junction by roll diffusion, and using ultrasonic atomization of phosphoric acid, thereby being nontoxic and nonpolluting, and achieving a uniform diffusion junction; and disposing siliconnitride antireflection layers on the front and back sides of the substrate; finally forming finger electrodes on the front and back sides by a silk-screen printing and sintering process. The method is suitable for the production technology of polycrystalline silicon 90-120[mu]m thick. Compared with a method for preparing a conventional polycrystalline silicon cell 180[mu]m thick, the method can reduce the thickness of the cell under the premise of ensuring a fragmentation rate, ensures battery efficiency, is simple in process, and low in cost. The method also solves the problem that the thincell is likely to be bent and is fragile, and can be industrialized by experimental verification.

Owner:HEBEI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com