Large-angle packaged object air cushion conveyer

A large-angle, conveyor technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of unable to set up supporting parts, unable to meet the long-distance transportation of weighted items, etc., achieve good promotion and application value, simple and reliable structure , with the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

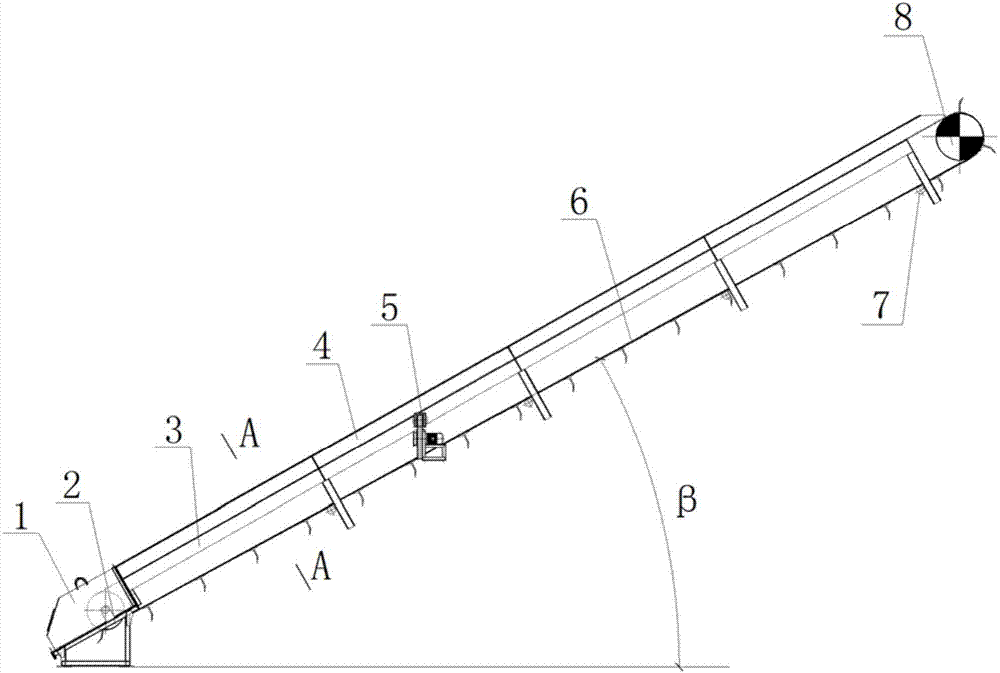

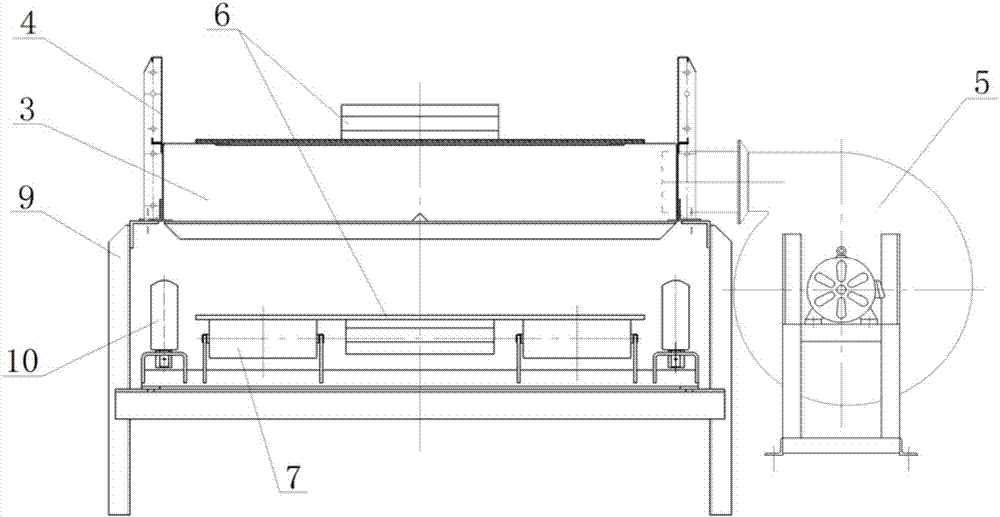

[0035] Combine below Figure 1-8 Describe in detail the technical scheme of the air cushion conveyor for large-angle items:

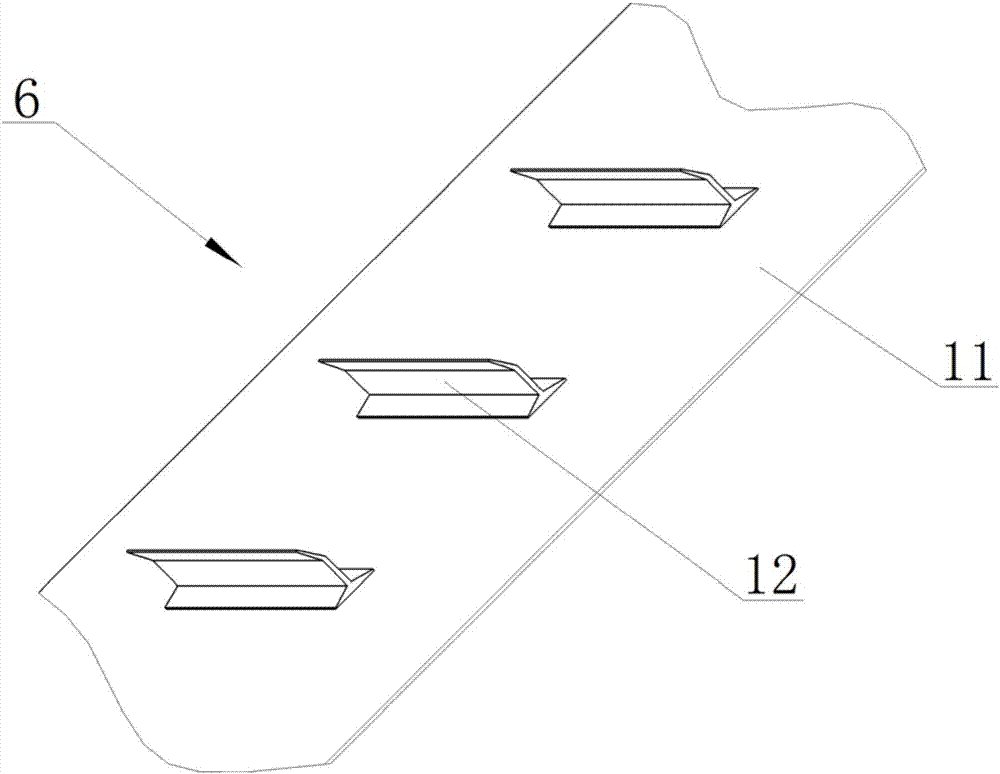

[0036]The air-cushion conveyor for large-angle items includes a partition conveyor belt 6, and the partition conveyor belt 6 includes a base belt 11 and several intermediate partitions 12, and the width of the intermediate partitions 12 is smaller than that of the base belt 11. Including the inclined lifting section, the inclined lifting section is provided with an air chamber 3, the air chamber 3 is arranged as a straight closed cavity along the inclined li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com