Film transfering mechanism with integrated continuously processing device

A technology of transfer film and transfer layer, which is applied in the direction of transfer printing, rotary printing machine, printing of special varieties of printed matter, etc., to achieve the effect of reliable monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

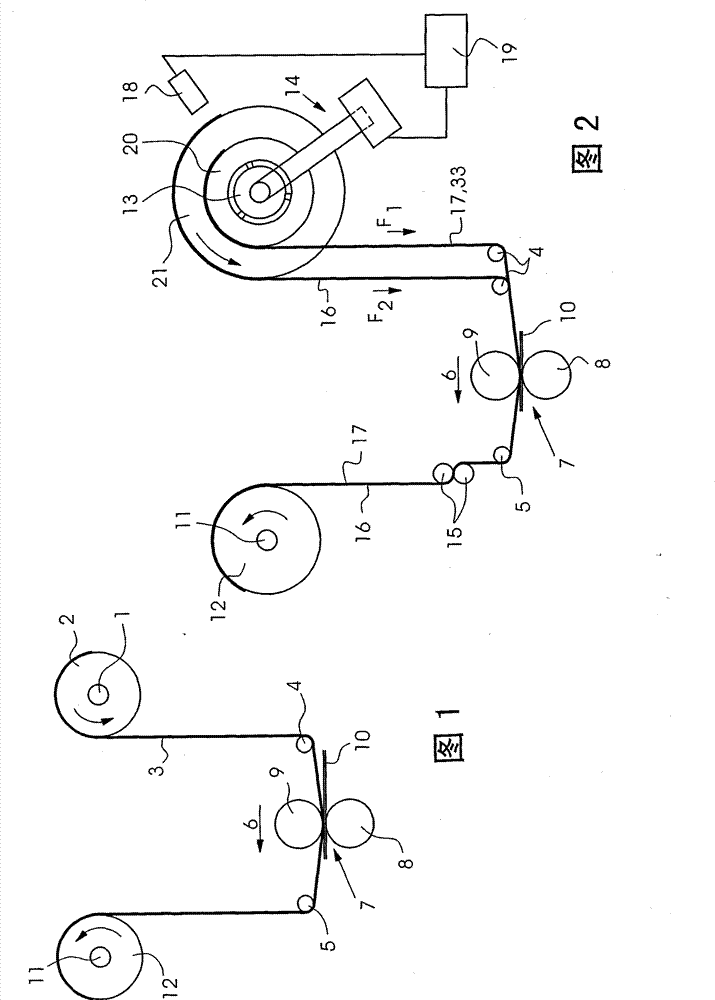

[0068] figure 1 A device according to the prior art is shown for transferring a transfer layer from a carrier film to a printing material 10 , the transfer layer and the carrier film together forming the transfer film.

[0069] A transfer film tape 3 is wound on a transfer film stock roll 2 . The transfer film stock roll 2 is provided on a stock shaft 1 which rotates in the direction indicated by the arrow. A drive (not shown here) can be provided for rotating the reserve shaft 1 .

[0070]The reserve shaft 2 is fixedly connected to the reserve shaft 1 , whereby the rotation of the reserve shaft 1 is directly transmitted to the reserve shaft 2 . In this way, the transfer film web 3 is unwound from the supply shaft 1 and transported via deflection rollers 4 to the transfer nip 7 . Several deflection rollers 4 can also be provided in order to achieve a corresponding course of the transfer path of the transfer film web 3 .

[0071] The transfer film web 3 is guided in direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com