High-precision suspension array belt metering scale

A belt weighing scale and suspension array technology, which is applied in the field of high-precision suspension array belt weighing scales, can solve the problems of inability to adopt multi-point balance method, inability to solve the problems of conveyor belt, deviation measurement accuracy, etc., and achieves accurate and reliable weight measurement and transmission. The effect of few force links and large bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

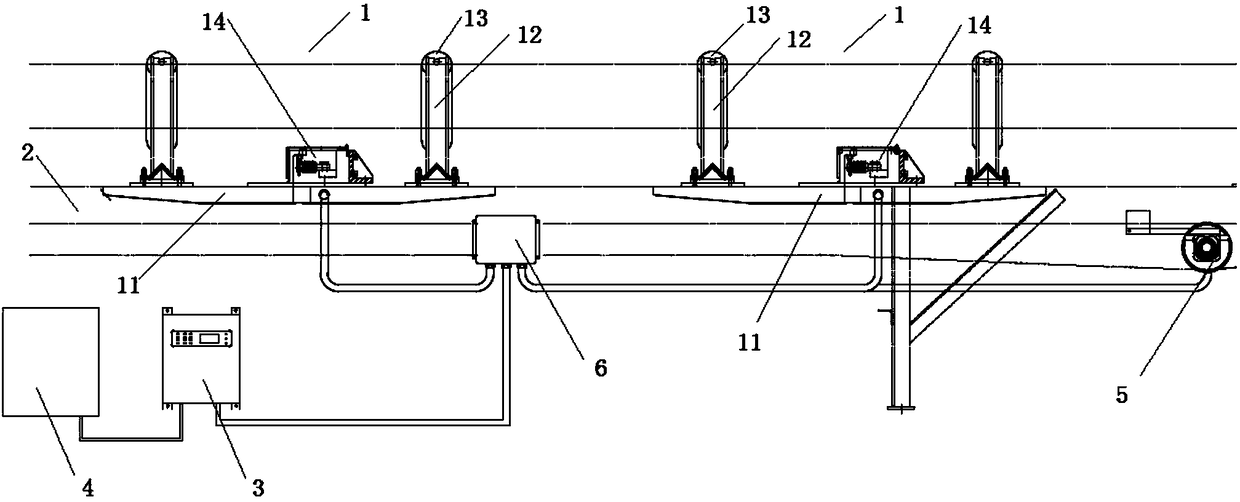

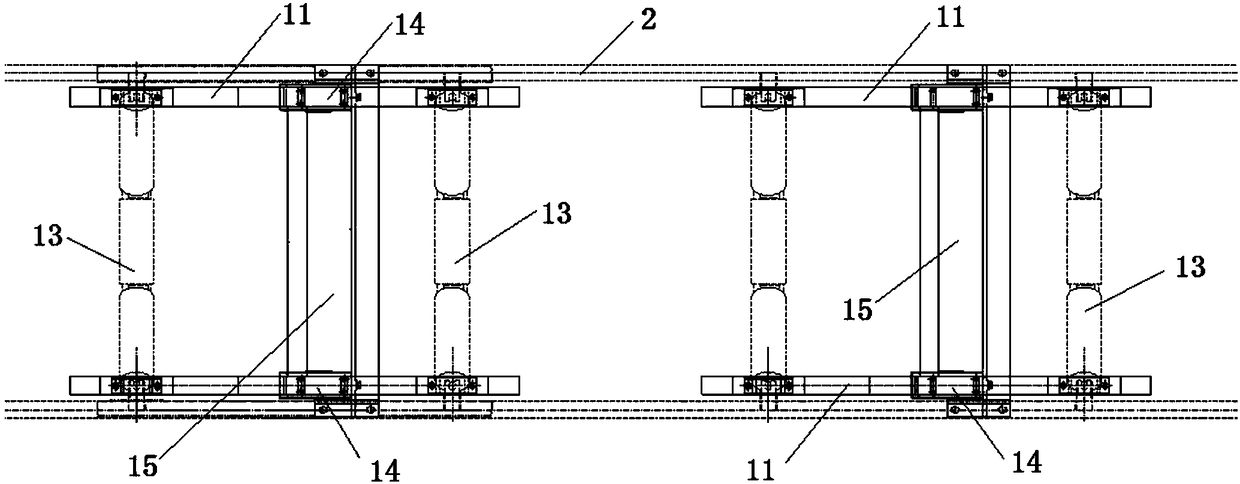

[0020] Such as figure 1 The shown a kind of high-precision suspension array belt weighing scale of the present invention comprises multiple groups of full-suspension scale groups 1 evenly distributed and installed on the frame 2 of the belt conveyor, and the number of the full-suspension scale groups 1 is according to It needs to be set up, and the details are not limited. The full-suspension scale group 1 includes two weighing bridges 11 arranged on the frames 2 on both sides, and each weighing bridge 11 is provided with a plurality of weighing idler brackets 12 , the number of the weighing idler bracket 12 is not specifically limited, and the number can be set according to needs, and the weighing idler bracket 12 is provided with a weighing idler 13, such as figure 2 As shown, a load-bearing beam 15 is arranged between the two weighing bridges 11, and two load cells 14 are arranged on the load-bearing beam 15, and the load cells 14 are all connected to the totalizer 3, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com