Welding method for high-carbon-equivalent strip steel in continuous annealing

A technology with high carbon equivalent and welding method, which is applied in the direction of welding equipment, furnace type, furnace, etc., can solve the problems that the stability of supercooled austenite cannot pass, the welding quality cannot be obtained, optimization, etc., and achieve the optimization of coil stability , Improve enterprise productivity and economic benefits, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0022] Weld the chilled strip steel coil at the entrance of the continuous annealing furnace. The thickness of the strip steel is shown in Table 2. The welding method adopts narrow lap welding. During the welding process, the high carbon equivalent steel coil A and the low carbon equivalent steel coil B are welded. The carbon equivalent steel coil B is welded with another high carbon equivalent steel coil A, that is, the high carbon equivalent and low carbon equivalent steel coils are welded alternately according to the A-B-A-B-A-B... method, high and low The weight percent content of C, Mn, Cr, Mo, V, Ni and Cu of carbon equivalent steel coils is shown in Table 1, and the carbon equivalent is shown in Table 2. The formula for calculating carbon equivalent is Ceq=[C+Mn / 6+(Cr+Mo +V) / 5+(Ni+Cu) / 15]*100%.

[0023] Table 1

[0024]

[0025] Table 2

[0026]

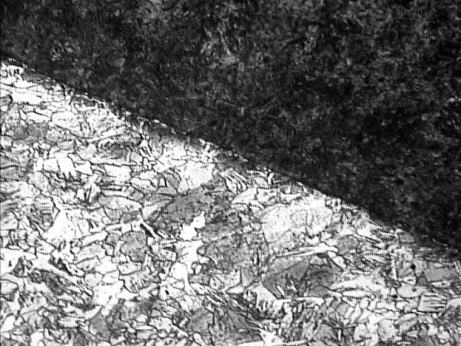

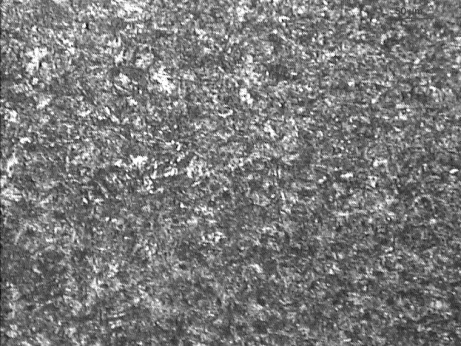

[0027] The microstructure of the welding seam of the strip steel in Example 1-10 was inspected, and the inspection r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com