Feeding and cutting mechanism and method

A cutting and stripping technology, which is applied in the field of lithium battery automation equipment, can solve problems such as mechanical cam metal collision, pole piece pulling, mechanical shock and vibration, and achieve the effect of avoiding the risk of broken tape and avoiding mechanical shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

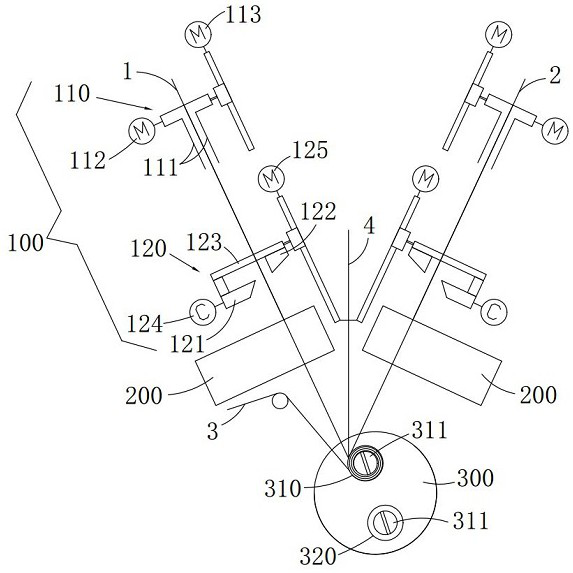

[0028] This embodiment is described by taking the feeding and cutting of the pole piece material tape as an example, and other embodiments can also be set as the feeding and cutting operation of other tapes. figure 1 As shown in , the cutting direction of the pole piece web is perpendicular to the conveying direction of the pole piece web.

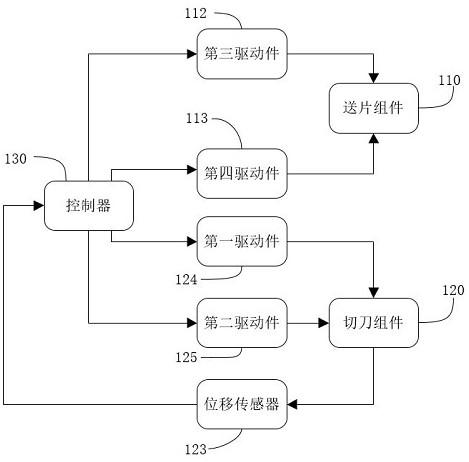

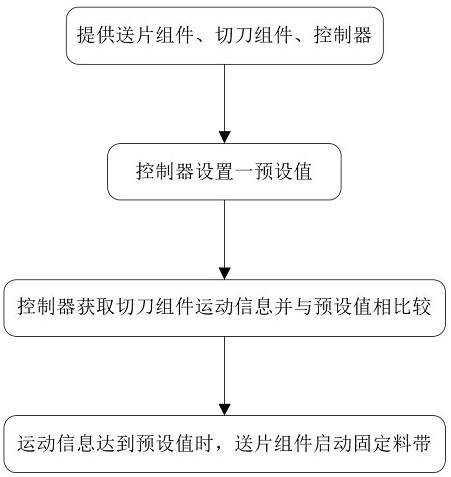

[0029] like figure 1 As shown, the feeding cutting mechanism 100 in this embodiment includes a sheet feeding assembly 110 and a cutting knife assembly 120 . A pre-rolling mechanism 200 is provided downstream of the feeding cutting mechanism 100 along the conveying direction of the pole piece material belt. The pre-rolling mechanism 200 is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com