The Method of Preventing Strip Breakage in Weld Seam of Thin Strip Steel

A strip steel welding seam and thin material technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large tension, enlargement, and broken strips of strip steel, and achieve reduced storage, reduced tension, Avoid the effect of weld tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

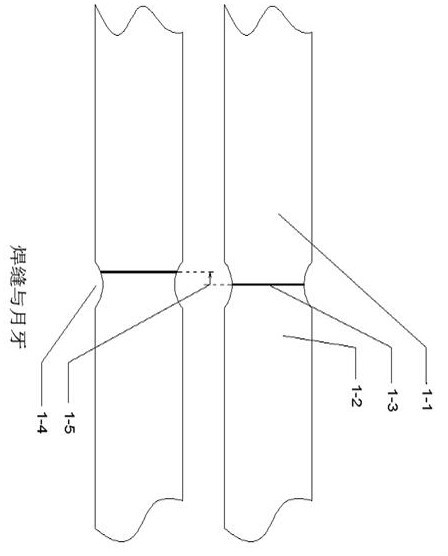

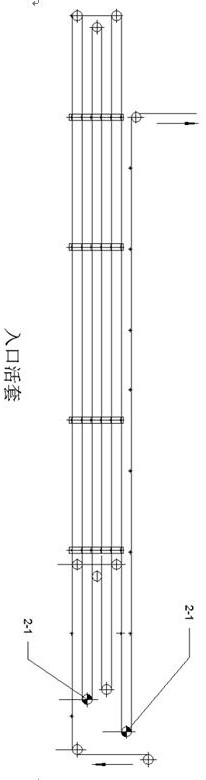

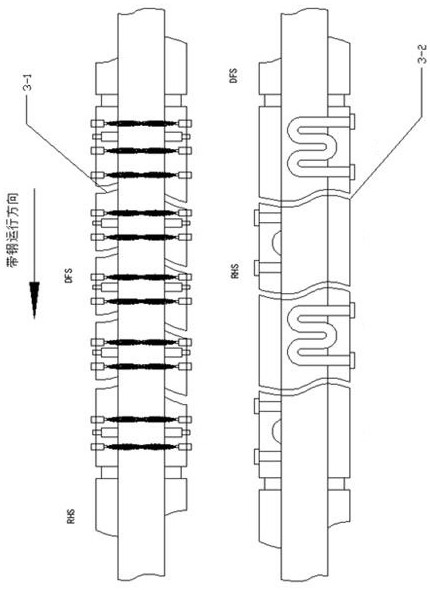

[0018] Embodiment 1: see Figure 1-Figure 5, a kind of method that prevents thin strip steel weld seam from being broken, described method comprises the following steps: 1) welding control; 2) entrance looper control; 3) continuous annealing control, 4) air knife control, 5) flattening correction control. The step 1) welding control; including using a wooden hammer to verify the weld 1-3 and a wooden hemispherical hammer to carry out a hammering test on the weld 1-3; Hammering at 15 cm and the middle position, if there is no cracking, the weld 1-3 is qualified; if cracking occurs, a second re-welding is required; the edge weld is set to asymmetrical edge filling operation, when the weld is on the crescent When the shearing position is ready to fill the edge, jog the position of the weld seam forward or backward by 5-10CM to ensure that after shearing, there is more than 2CM shearing amount at the weld seam. In this way, it can prevent the stress concentration at the weld 1-3...

Embodiment 2

[0030] see Figure 1-Figure 5 , in the implementation process of embodiment 1, when the width switching process in thin material production is aimed at, when the asymmetry of the weld seam becomes a shear crescent, it is necessary to move the weld seam position 5-10CM to the wider direction to ensure that after shearing , There is more than 2CM shear at the weld. 150 meters before entering the furnace, reduce the tension of the strip steel twice, the reduction is 15-20%, based on the tension of the narrow material, after passing the weld, increase the tension twice again to the normal tension of the strip steel in the current furnace area. The side baffles are opened 15 meters before the weld, and the opening distance is 50MM added to the width of the wide steel strip.

[0031] The tension leveler adopts the 3MM welding seam mode. At the same time, after the welding seam passes, the upper roller 1#, 2#, and 4# are pressed down first, and the 3# roller is lifted, and then 3#, ...

Embodiment 3

[0033] During the implementation of Example 1, send samples to detect the aluminum content 4 hours before switching thin materials. If the aluminum content is too low or too high, you can continuously add E1 ingots or D ingots for adjustment to ensure that after switching, the aluminum in the zinc liquid The content is controlled at 0.2-0.25%, and the temperature of the zinc liquid can be raised one roll in advance to ensure that the temperature remains at 465-467°C after switching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com