Method and device applied to limit variable-specification rolling of leveler

A technology of skin-pass mill and variable specification, applied in the field of skin-pass mill, can solve the problems of slowdown of annealing furnace and large strip cutting loss, and achieve the effect of ensuring running speed and solving speed reduction of annealing furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

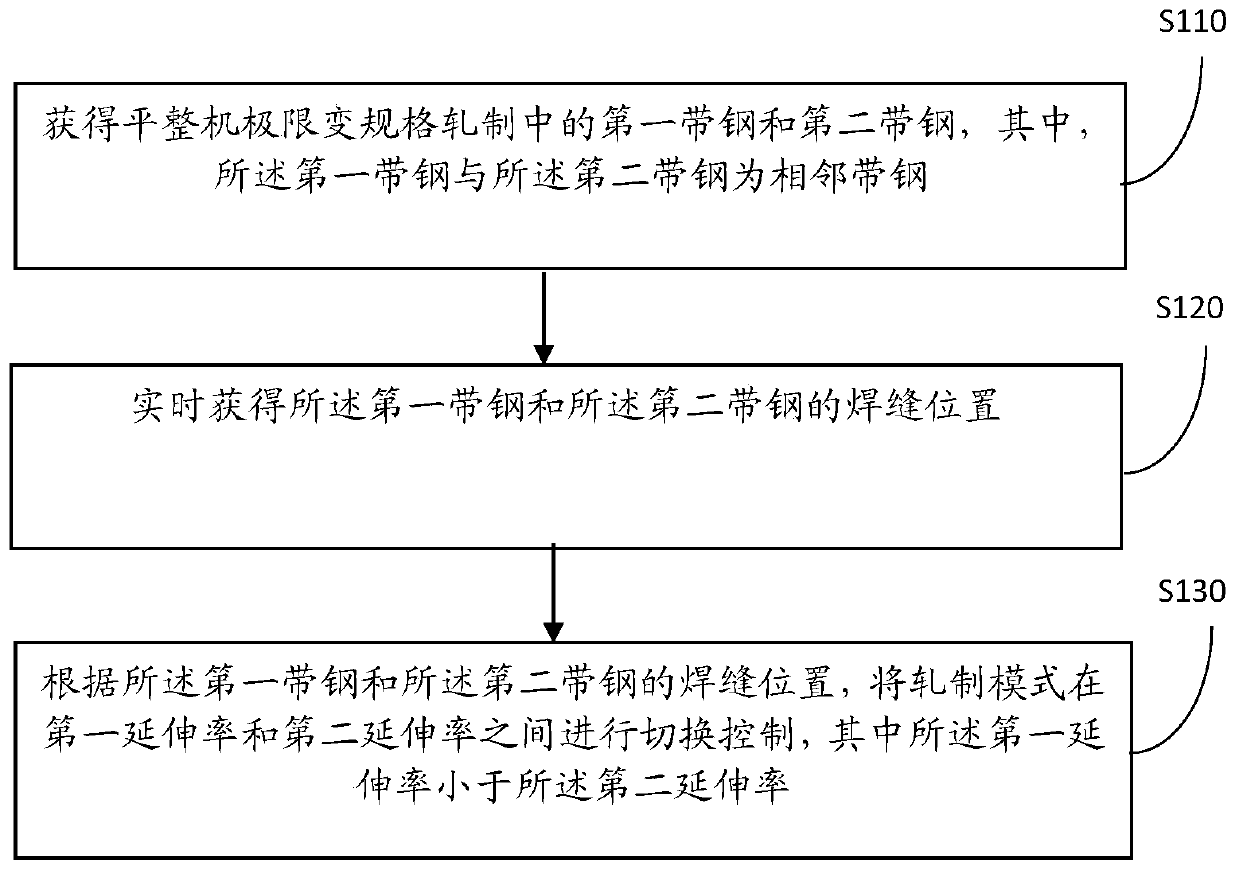

[0052] figure 1 It is a schematic flow chart of a method applied to extreme variable-gauge rolling in a temper mill in an embodiment of the present invention. The embodiment of the present invention provides a method applied to the extreme variable specification rolling of the temper mill, such as figure 1 As shown, the method includes:

[0053] Step 110: Obtain the first steel strip and the second steel strip in the extreme variable-gauge rolling of the skin pass mill, wherein the first steel strip and the second steel strip are adjacent steel strips.

[0054] Step 120: Obtain the weld seam positions of the first steel strip and the second steel strip in real time.

[0055] Step 130: According to the weld position of the first steel strip and the second steel strip, switch the rolling mode between the first elongation rate and the second elongation rate, wherein the first elongation rate is less than The second elongation.

[0056] Specifically, when the temper mill under...

Embodiment 2

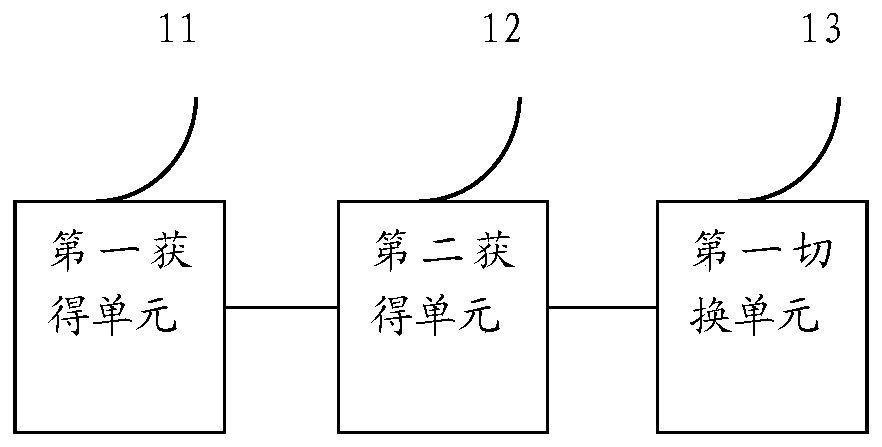

[0067] Based on the same inventive concept as the method applied to the extreme variable specification rolling of the temper mill in the foregoing embodiment, the present invention also provides a device applied to the extreme variable specification rolling of the temper mill, such as figure 2 As shown, the device includes:

[0068] The first obtaining unit 11, the first obtaining unit 11 is used to obtain the first steel strip and the second steel strip in the extreme variable-gauge rolling of the skin pass mill, wherein the first steel strip and the second strip The steel is the adjacent strip;

[0069] A second obtaining unit 12, the second obtaining unit 12 is used to obtain the weld seam positions of the first steel strip and the second steel strip in real time;

[0070] A first switching unit 13, the first switching unit 13 is used to set the rolling mode between the first elongation rate and the second elongation rate according to the weld position of the first steel ...

Embodiment 3

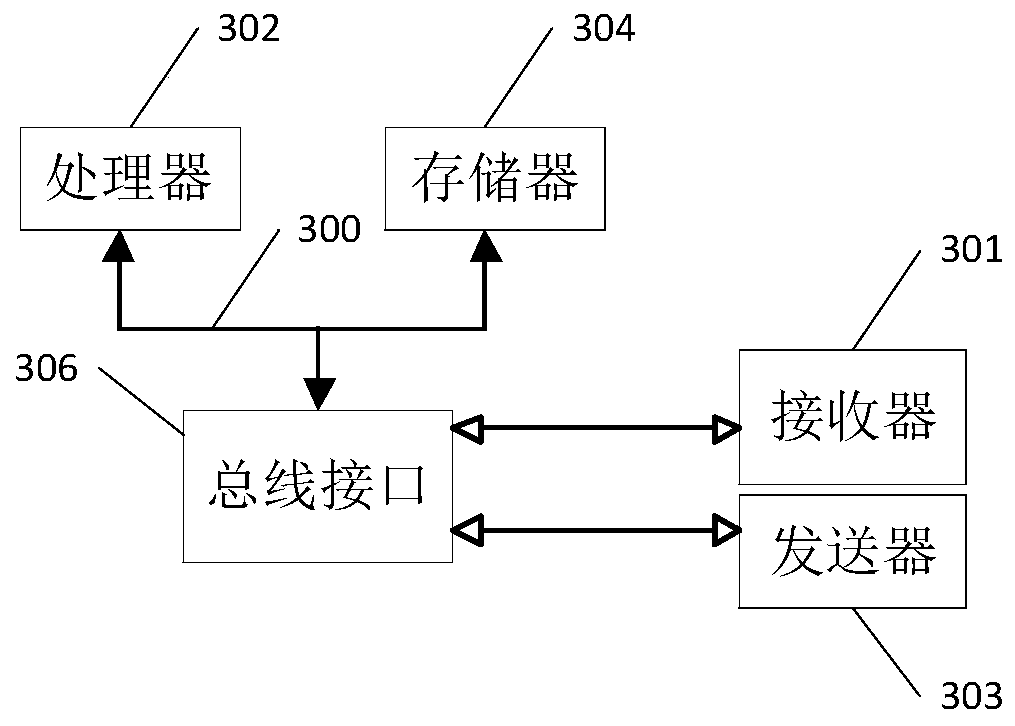

[0092] Based on the same inventive idea as the method applied to the extreme variable-size rolling of the temper mill in the foregoing embodiments, the present invention also provides a device applied to the extreme variable-size rolling of the temper mill, on which a computer program is stored , when the program is executed by the processor, the steps of any one of the above-mentioned methods applied to extreme variable-gauge rolling of the temper mill are realized.

[0093] Among them, in image 3 In, bus architecture (represented by bus 300), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits linked together. The bus 300 may also link together various other circuits, such as peripherals, voltage regulators, and power management circuits, etc., which are well known in the art and thus will not be further described herein. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com