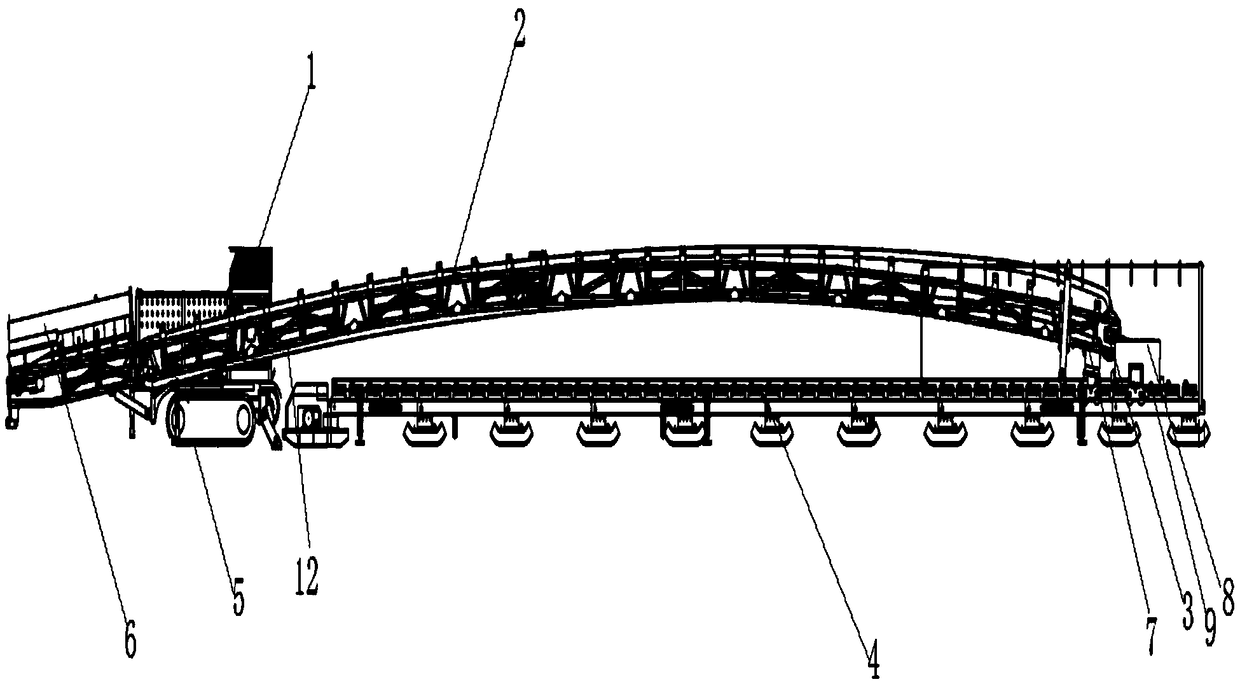

Self-walking two-conveying transfer machine for coal mine

A self-propelled, reloading machine technology, applied in the field of power machinery, can solve the problems of low efficiency and high cost of tunneling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

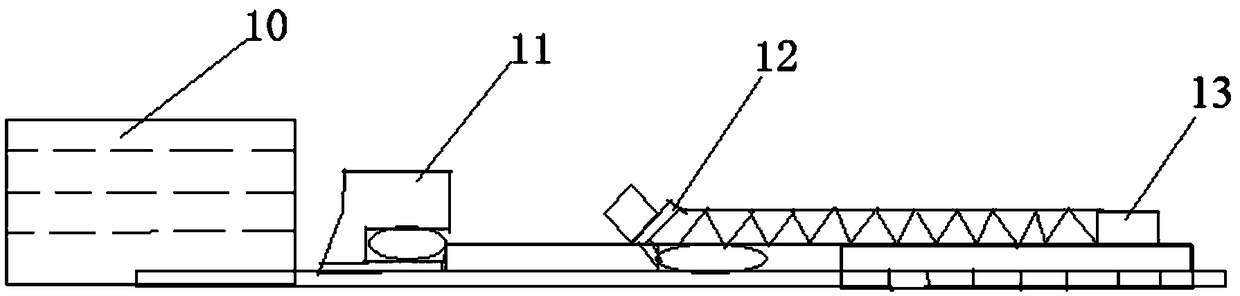

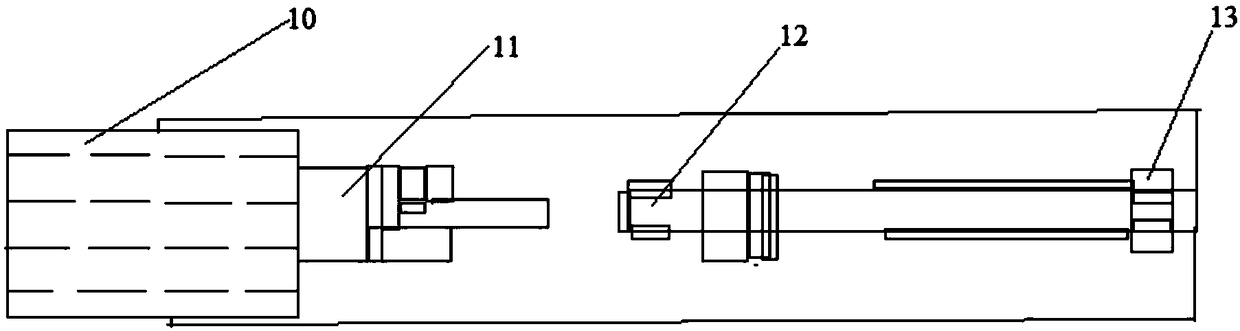

[0027] Embodiment 1: The total length of a self-propelled two-rotation loader used in coal mines of the present invention is 31700mm, the total length of the tail slideway extending along the belt conveyor is 25000mm, and the effective stroke of the slideway is 22500mm; it can meet the 22m excavation scale per shift. like figure 2 , image 3As shown, taking continuous coal mining machine 11 as an example to form a roadway by mining coal twice, the roadway cross-section size width*height is 5500*4200m, and the continuous coal mining machine 11 is aligned with the right side of the coal seam 10 to start eating the first coal. A kind of self-propelled two-running loader used in coal mines of the present invention carries the coal hopper 6 and aligns below the scraper slide of the continuous coal mining machine 11. The first knife coal is eaten into 6-8m, and the power walking part 1 controls the coal-bearing hopper 6 to keep the position of the coal-bearing hopper 6 directly be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com