Free float type belt weighing device

A belt weighing and floating technology, applied in the direction of measuring devices, detailed information of weighing equipment, weighing equipment for continuous material flow, etc., can solve the problem that the limiting force or internal stress cannot be released well, and cannot provide high precision Weighing measurement, interference with accurate measurement of gravity and other problems, to achieve the effect of accurate and reliable weight measurement, wide practicability, and strong anti-eccentric load ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

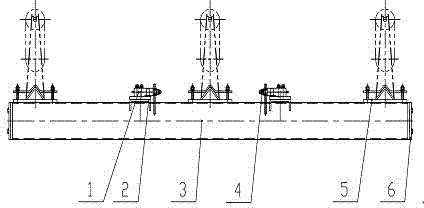

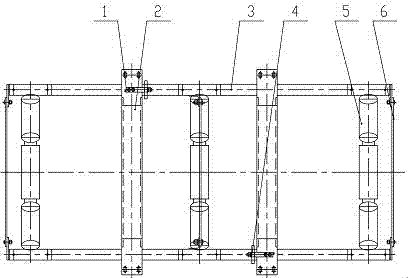

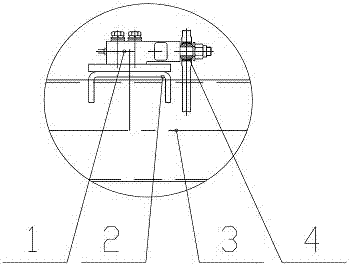

[0017] Such as figure 1 , 2 , 3 shows a free-floating belt weighing device with three idlers, the weighing device is mainly composed of a load cell 1, a support beam 2, a support beam 3, a universal joint 4, a weighing idler bracket 5, and a connecting plate 6 components, wherein the weighing idler bracket 5 is three groups, and the weighing idler bracket 5, the connecting plate 6 and the support beam 3 are connected to form a weighing bridge. The three sets of weighing idler brackets 5 are all of trough-shaped idler structure, flat idler structure or V-shaped idler structure. In the middle of a weighing idler bracket 5, there are two symmetrically installed on the belt frame beam. Supporting beam 2, two supporting beams 2 are respectively located between three sets of weighing idler brackets 5, and two supporting beams 2 are provided with two load cells 1 arranged diagonally and oppositely, that is, one is installed on each supporting beam 2 The load cell 1, the force-beari...

Embodiment 2

[0019] Such as Figure 4 , Figure 5 As shown, it is a free-floating belt weighing device with double rollers. The weighing device is mainly composed of a load cell 1, a support beam 2, a support beam 3, a universal joint 4, a weighing idler bracket 5, and a connecting plate 6 , wherein the weighing idler bracket 5 is two groups, and the weighing idler bracket 5, the connecting plate 6 and the support beam 3 are connected to form a weighing bridge. The two sets of weighing roller brackets 5 are trough roller structures, flat roller structures or V-shaped roller structures, and a support beam 2 is arranged between the two weighing roller brackets 5, and the support beam 2 is installed on the belt frame On the beam, two load cells 1 arranged oppositely are arranged symmetrically at both ends of the support beam 2, and the two load cells 1 are respectively connected to the support beam 3 through universal joints 4, and the load-bearing end structure of the load cell 1 is Cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com