Coating apparatus

A coating device and coating technology, which is applied to the surface coating liquid device, coating, metal material coating process, etc., can solve the problems of device stoppage, bearing wear, etc., and achieve the effect of short soaking period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

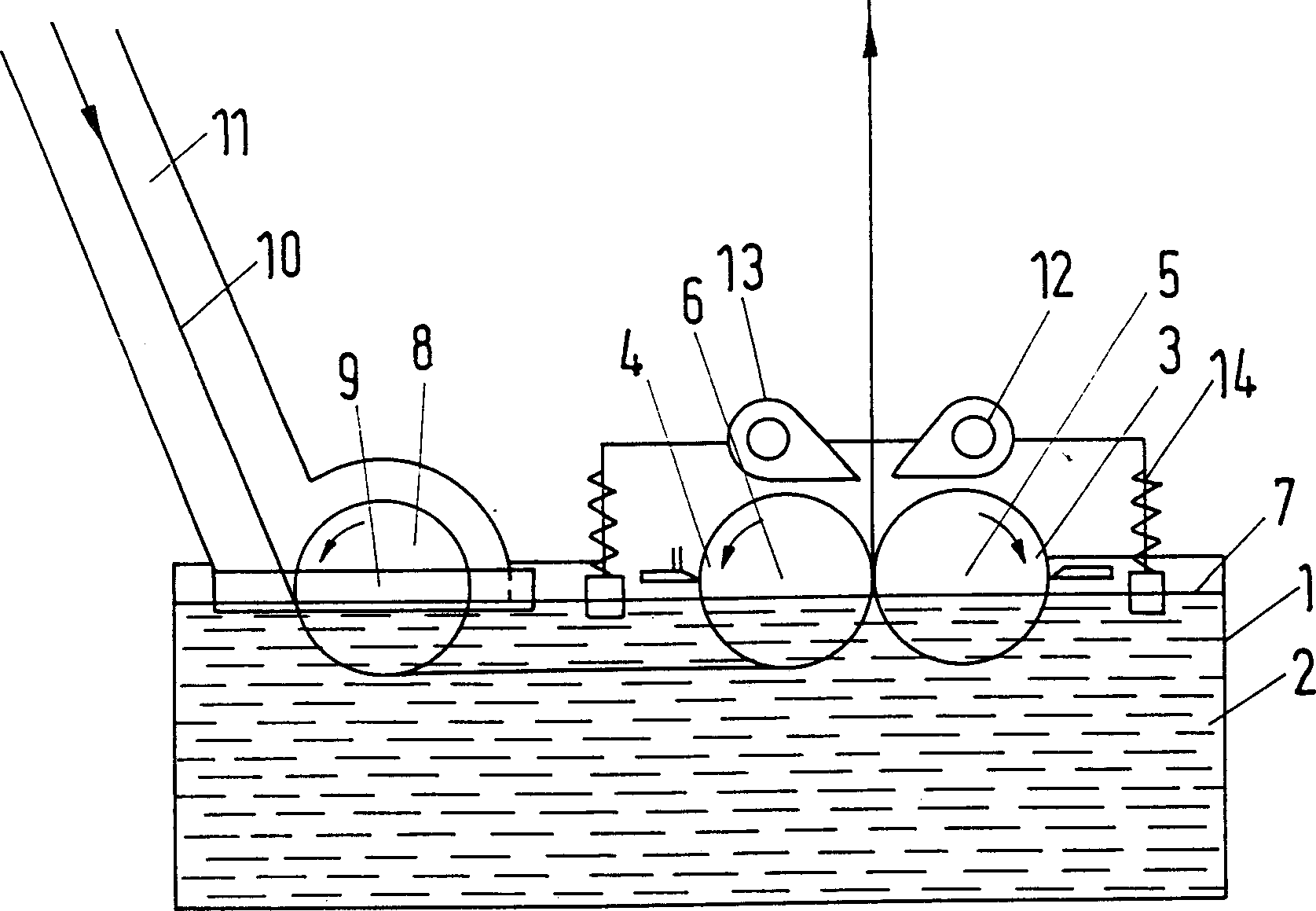

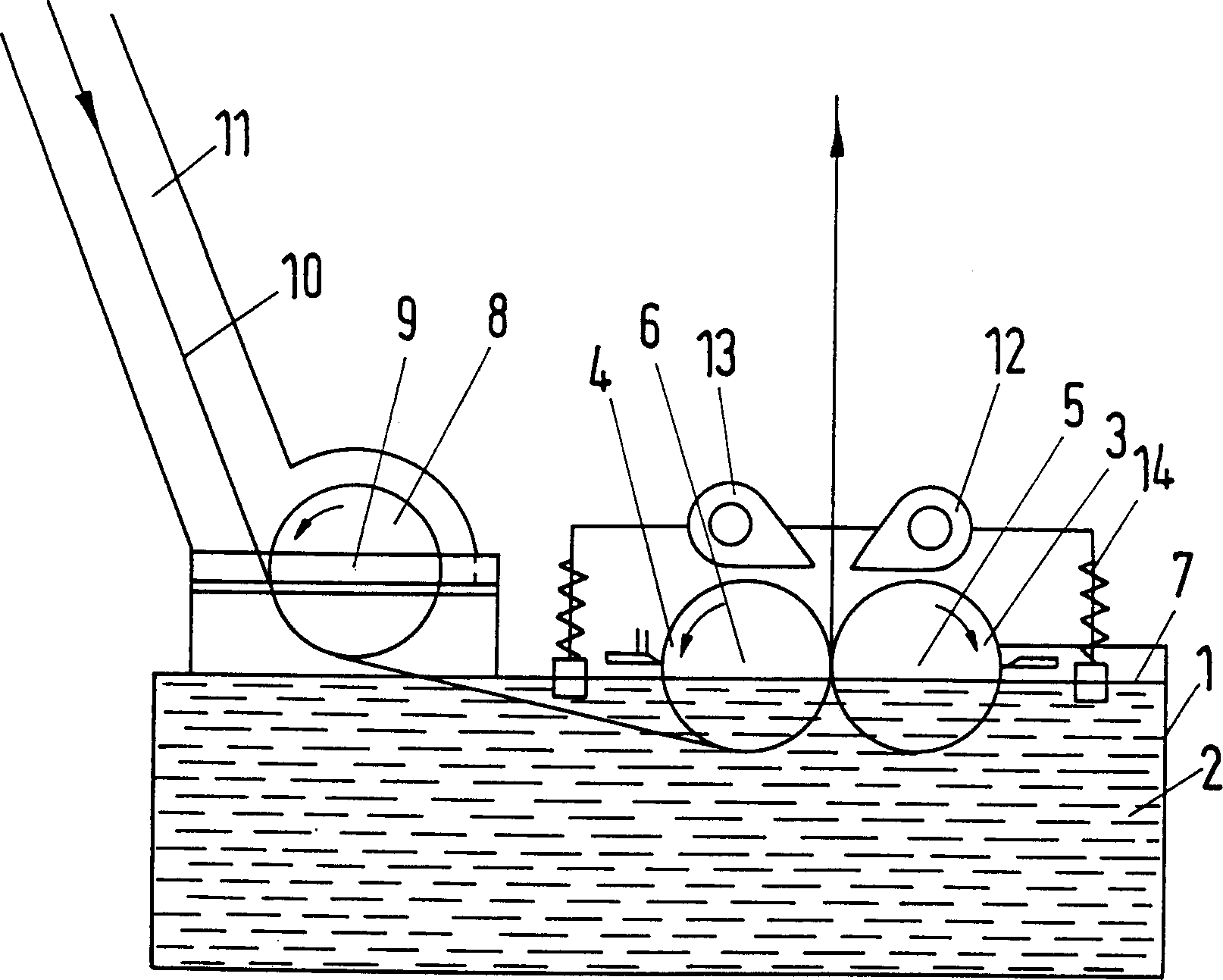

[0028] First of all figure 1 The coating device in is described according to its main structure, and a more detailed description is given in the description.

[0029] The coating device includes a paint container 1 and a coating tank 2 containing paint. The coating may include molten tin, zinc, aluminum, or multiple types of alloys, or water-soluble dyed powder. in figure 1 In the embodiment, the coating container 1 is a coating tank containing a coating tank 2.

[0030] The front coating drum 3 and the rear coating drum 4 are immersed in the coating bath, and their bearings 5 and 6 are respectively located above the upper bath liquid level 7 of the coating bath 2.

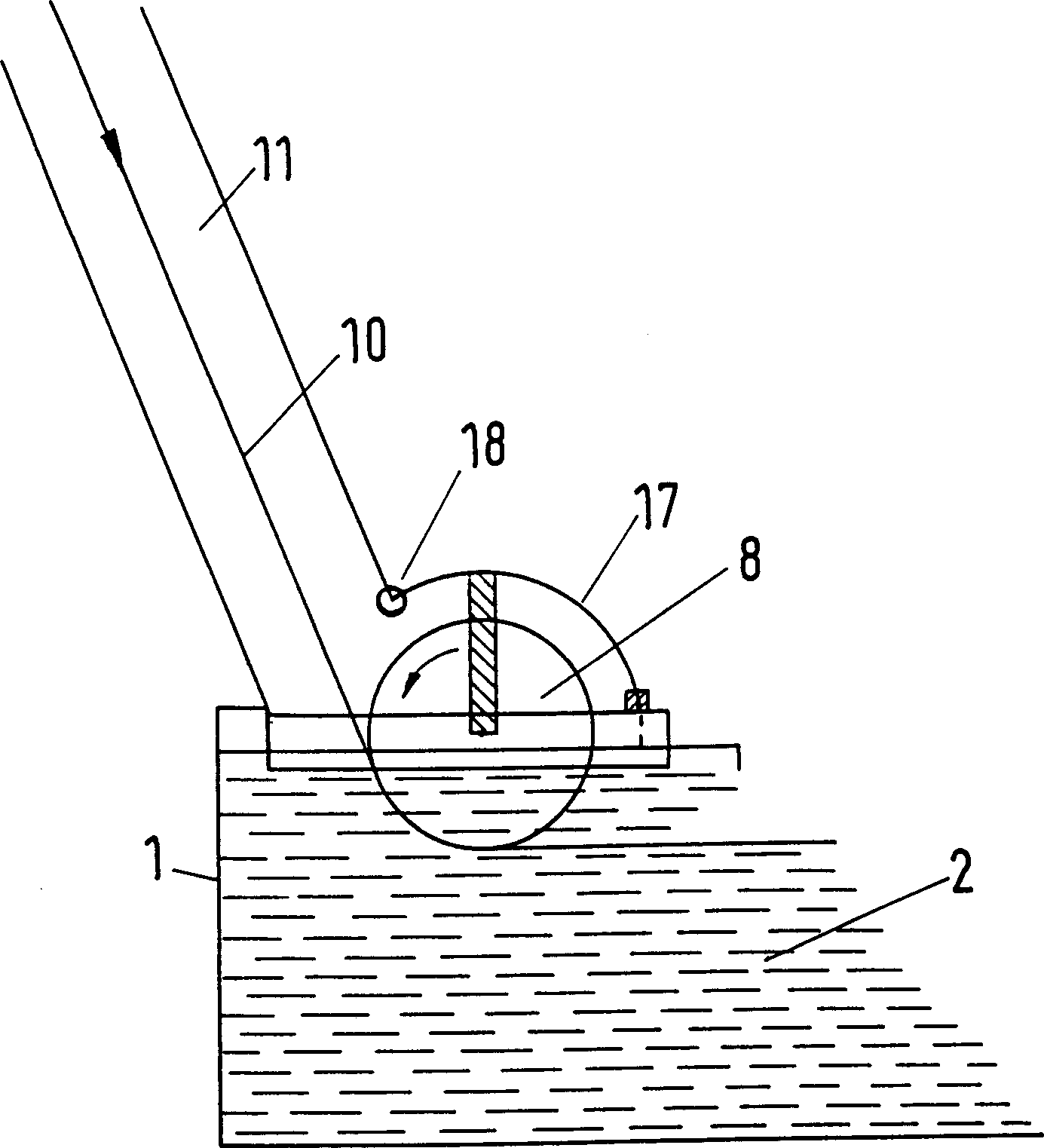

[0031] In this embodiment, the deflection roller 8 is also immersed in the coating bath 2. The bearing 9 of the drum is also located above the liquid level 7 of the upper bath of the coating bath 2.

[0032] The front and rear coating rollers 3 and 4 can be driven or not. The coating rollers 3 and 4 are separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com