A kind of anti-oxidation and light conversion agricultural plastic film and preparation method thereof

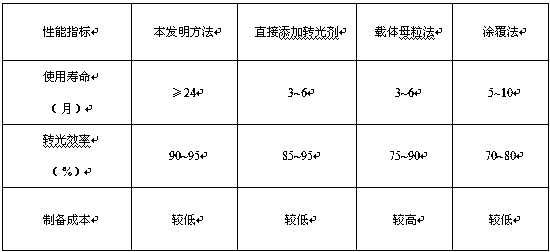

A plastic film and anti-oxidation technology, applied in chemical instruments and methods, botany equipment and methods, agriculture, etc., can solve the problems of reduced light transmission efficiency, short service life, fluorescence quenching, etc., and achieve simple and controllable preparation, Cost reduction and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

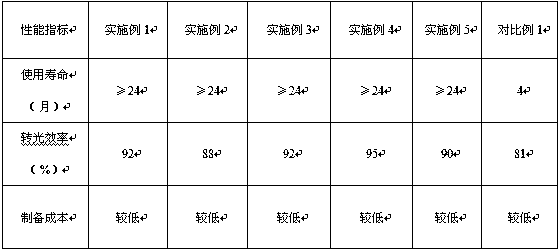

Embodiment 1

[0031] A method for preparing an anti-oxidation light-transforming agricultural plastic film, the preparation process is as follows:

[0032] (1) Disperse the light-changing agent 1,4-bis(o-cyano-styryl)benzene and polyethylene wax in a high-speed disperser at a mass ratio of 100:5, so that the polyethylene wax evenly coats the light-changing agent to improve The light-changing agent is ready for use; take 100 parts by weight of ethylene-vinyl acetate copolymer, add 300 parts by weight of absolute ethanol, stir and heat up to 50°C, then add 10 parts by weight of sodium hydroxide, continue to stir and heat up to 60°C, and react After 30 minutes, add 10 parts by weight of a modified light-changing agent; continue to react for 10 minutes, filter the reaction product, wash repeatedly with deionized water, and spray dry to obtain a powdered ethylene-vinyl alcohol copolymer-coated light-changing agent. agent colloid;

[0033] (2) Use two casting machines to cast the upper and lower...

Embodiment 2

[0042] A method for preparing an anti-oxidation light-transforming agricultural plastic film, the preparation process is as follows:

[0043] (1) Disperse the light-changing agent 6,7-pyranocoumarin and polyethylene wax in a high-speed disperser at a mass ratio of 100:8, so that the polyethylene wax evenly coats the light-changing agent to obtain a modified light-changing agent Standby: Take 100 parts by weight of ethylene-vinyl acetate copolymer, add 400 parts by weight of absolute ethanol, stir and heat up to 50°C, then add 15 parts by weight of sodium hydroxide, continue to stir and heat up to 60°C, after reacting for 45 minutes, add 15 parts by weight of the modified light-changing agent; continue to react for 15 minutes, filter the reaction product, repeatedly wash with deionized water, and spray dry to obtain powdery ethylene-vinyl alcohol copolymer-coated light-changing agent micelle;

[0044] (2) Use two casting machines to cast the upper and lower layers of polyethyle...

Embodiment 3

[0047] A method for preparing an anti-oxidation light-transforming agricultural plastic film, the preparation process is as follows:

[0048] (1) Disperse the light-changing agent 6,7-furanocoumarin and polyethylene wax in a high-speed disperser at a mass ratio of 100:5, so that the polyethylene wax evenly coats the light-changing agent to obtain a modified light-changing agent for use Take 100 parts by weight of ethylene-vinyl acetate copolymer, add 400 parts by weight of absolute ethanol, stir and heat up to 50°C, then add 15 parts by weight of sodium hydroxide, continue stirring and heat up to 60°C, after reacting for 45min, add 15 Modified light-changing agent in parts by weight; continue to react for 15 minutes, filter the reaction product, repeatedly wash with deionized water, and spray dry to obtain powdery ethylene-vinyl alcohol copolymer-coated light-changing agent micelle;

[0049] (2) Use two casting machines to cast the upper and lower layers of polyethylene film, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com