Preparation method of crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of waste of special gas flow, low output, and inability to adjust belt speed, etc., to increase output, improve production efficiency, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1, making a red solar cell. It includes the following steps:

[0013] (1) Texture and diffuse the raw silicon wafers; control the texturing depth at 0.2-1.0 μm, and control the diffusion as a shallow junction to be less than 0.1-0.2 μm;

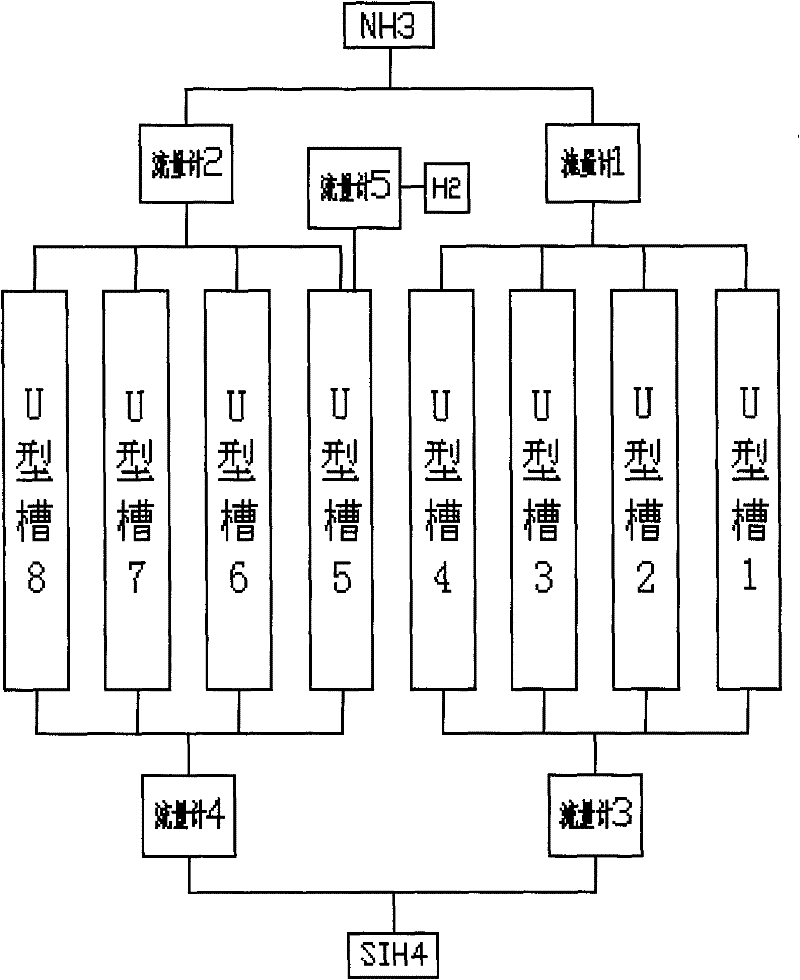

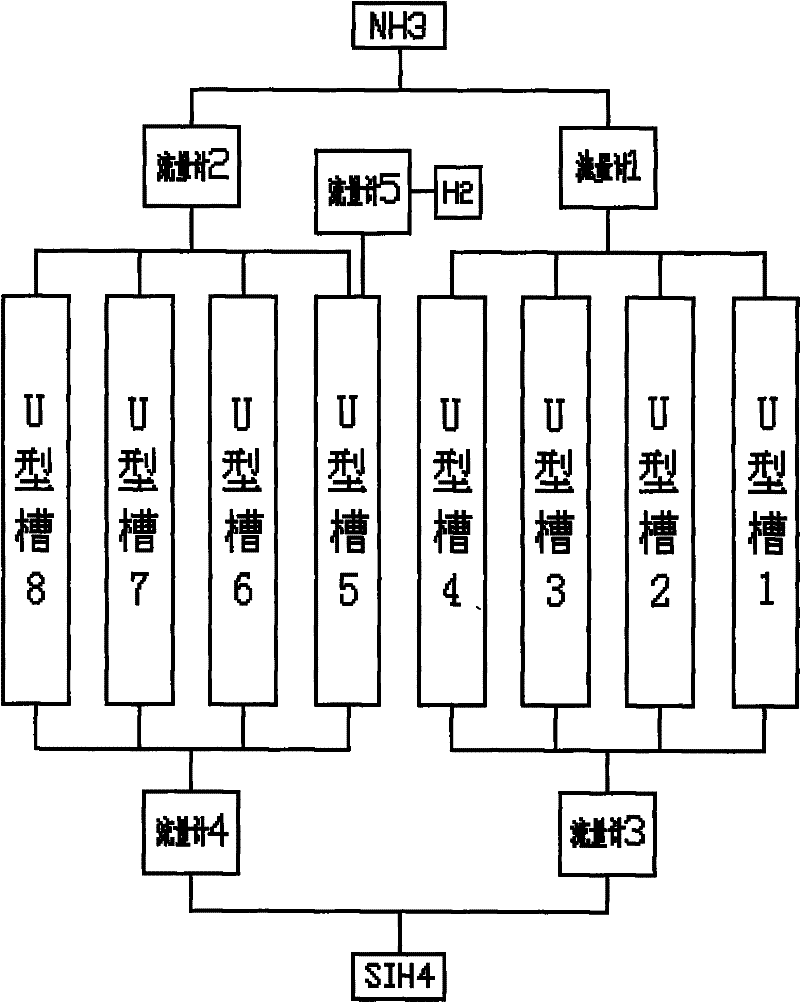

[0014] (2), use PECVD equipment to coat silicon nitride antireflection film; adjust flow meter 1 and flow meter 3 respectively, control the ammonia gas entering U-shaped groove 1, U-shaped groove 2, U-shaped groove 3 and U-shaped groove 4 The flow rate of NH3 and silane SIH4 makes the flow ratio of ammonia NH3 and silane SIH4 be 6:5; adjust flowmeter 2 and flowmeter 4 respectively, control to enter U-shaped groove 5, U-shaped groove 6, U-shaped groove 7 and U-shaped groove The flow rate of ammonia NH3 and silane SIH4 in the type groove 8 makes the flow ratio of ammonia NH3 and silane SIH4 be 3: 1, 7: 2 and 4: 1, preferably 7: 2; Regulate flow meter 5, control The flow rate of the hydrogen H entering the U-shaped groove 5 is 2...

Embodiment 2

[0017] Embodiment 2, making a yellow solar battery sheet. It includes the following steps:

[0018] (1) Texture and diffuse the raw silicon wafers; control the texturing depth at 0.2-1.0 μm, and control the diffusion as a shallow junction to be less than 0.1-0.2 μm;

[0019] (2), use PECVD equipment to coat silicon nitride antireflection film; adjust flow meter 1 and flow meter 3 respectively, and control the ammonia gas entering U-shaped groove 1, U-shaped groove 2, U-shaped groove 3 and U-shaped groove 4 The flow rate of NH3 and silane SIH4 makes the flow ratio of ammonia NH3 and silane SIH4 be 6: 5; adjust flow meter 2 and flow meter 4 respectively, control to enter U-shaped groove 5, U-shaped groove 6, U-shaped groove 7 and U-shaped groove Ammonia NH3 and silane SIH4 flow in the type groove 8, make the flow ratio of ammonia NH3 and silane SIH4 be 3: 1, 7: 2 and 4: 1, preferably 4: 1; Regulate flow meter 5, control The flow rate of the hydrogen H entering the U-shaped gro...

Embodiment 3

[0022] Embodiment 3, making green solar cells. It includes the following steps:

[0023] (1) Texture and diffuse the raw silicon wafers; control the texturing depth at 0.2-1.0 μm, and control the diffusion as a shallow junction to be less than 0.1-0.2 μm;

[0024] (2), use PECVD equipment to coat silicon nitride antireflection film; adjust flow meter 1 and flow meter 3 respectively, and control the ammonia gas entering U-shaped groove 1, U-shaped groove 2, U-shaped groove 3 and U-shaped groove 4 The flow rate of NH3 and silane SIH4 makes the flow ratio of ammonia NH3 and silane SIH4 be 6: 5; adjust flow meter 2 and flow meter 4 respectively, control to enter U-shaped groove 5, U-shaped groove 6, U-shaped groove 7 and U-shaped groove Ammonia NH3 and silane SIH4 flow in the type groove 8, make the flow ratio of ammonia NH3 and silane SIH4 be 3: 1, 7: 2 and 4: 1, preferably 3: 1; Regulate flow meter 5, control The flow rate of the hydrogen H entering the U-shaped groove 5 is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com