Continuous processing system for steel strip

A processing system and technology for steel strips, applied in the field of continuous processing systems for steel strips, to achieve the effect of high strip speed and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

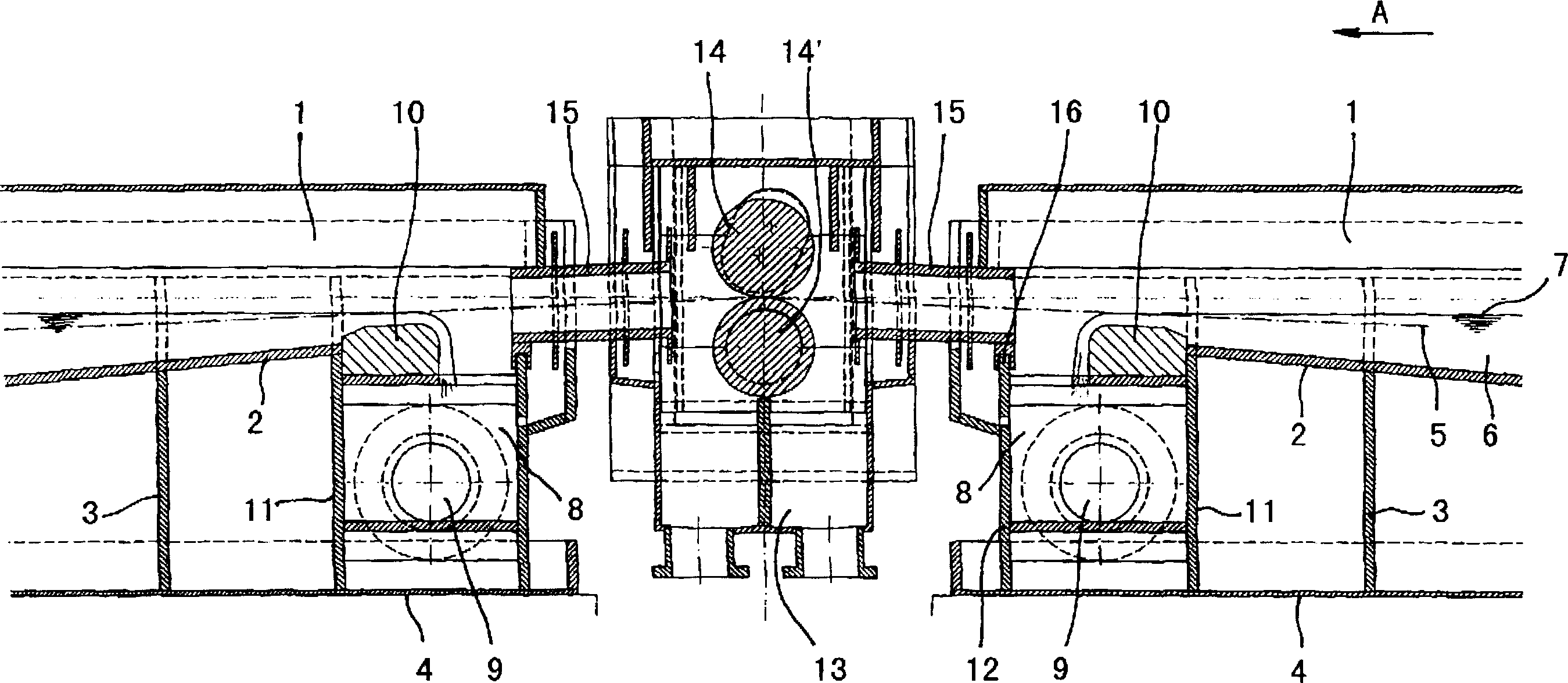

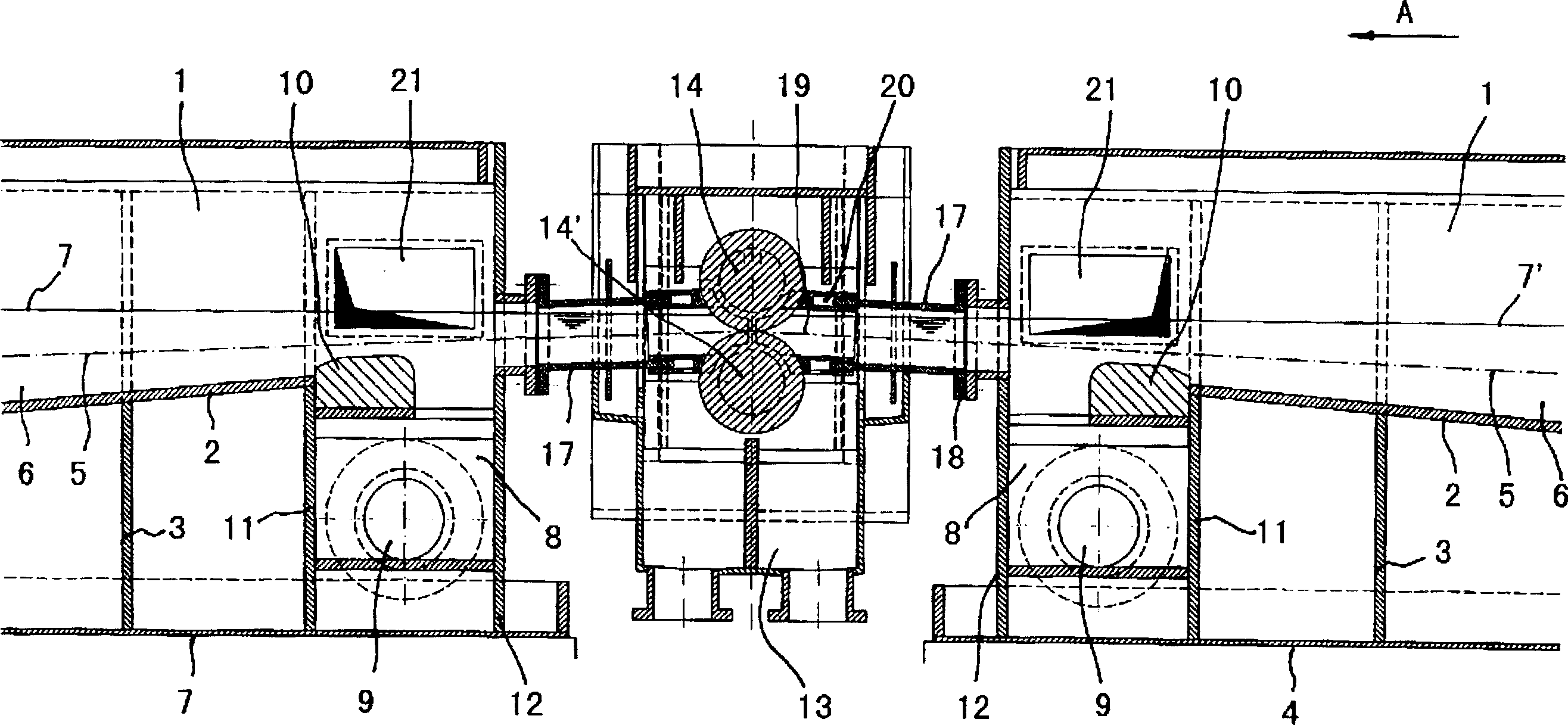

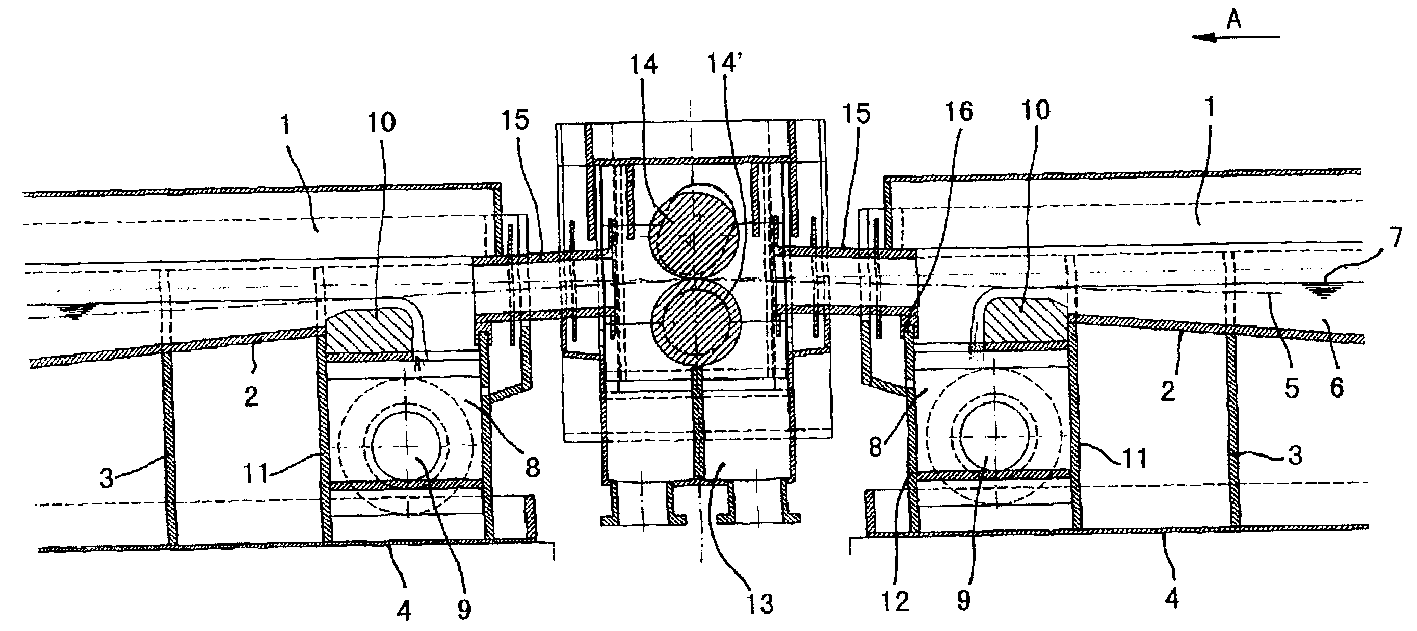

[0015] figure 1 A pickling tank 1 is shown, the bottom 2 of which is supported on a tray 4 with pillars 3 without seams. The steel strip 5 moves in the direction A in the processing liquid 6 with a liquid level of 7. At the end of the treatment tank 1 is provided an outlet tank 8 into which the liquid flows and is discharged through a laterally arranged discharge pipe 9. In order to better adjust the liquid level 7, a protective belt 10 that can best be drawn out is provided. The protective belt 10 is designed such that the steel belt 5 is slightly higher than the wall 11 of the outlet groove 8 when exposed from the liquid. Due to the expansion, the opposite wall 12 can move in the direction of arrow D within the disk 4.

[0016] The groove 13 for accommodating the press rolls 14, 14' is arranged separately from the groove 1. The top of this trough can be closed. At the other end of the treatment tank 1 is provided a tank 13 of the same type with press rolls 14, 14'. The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com