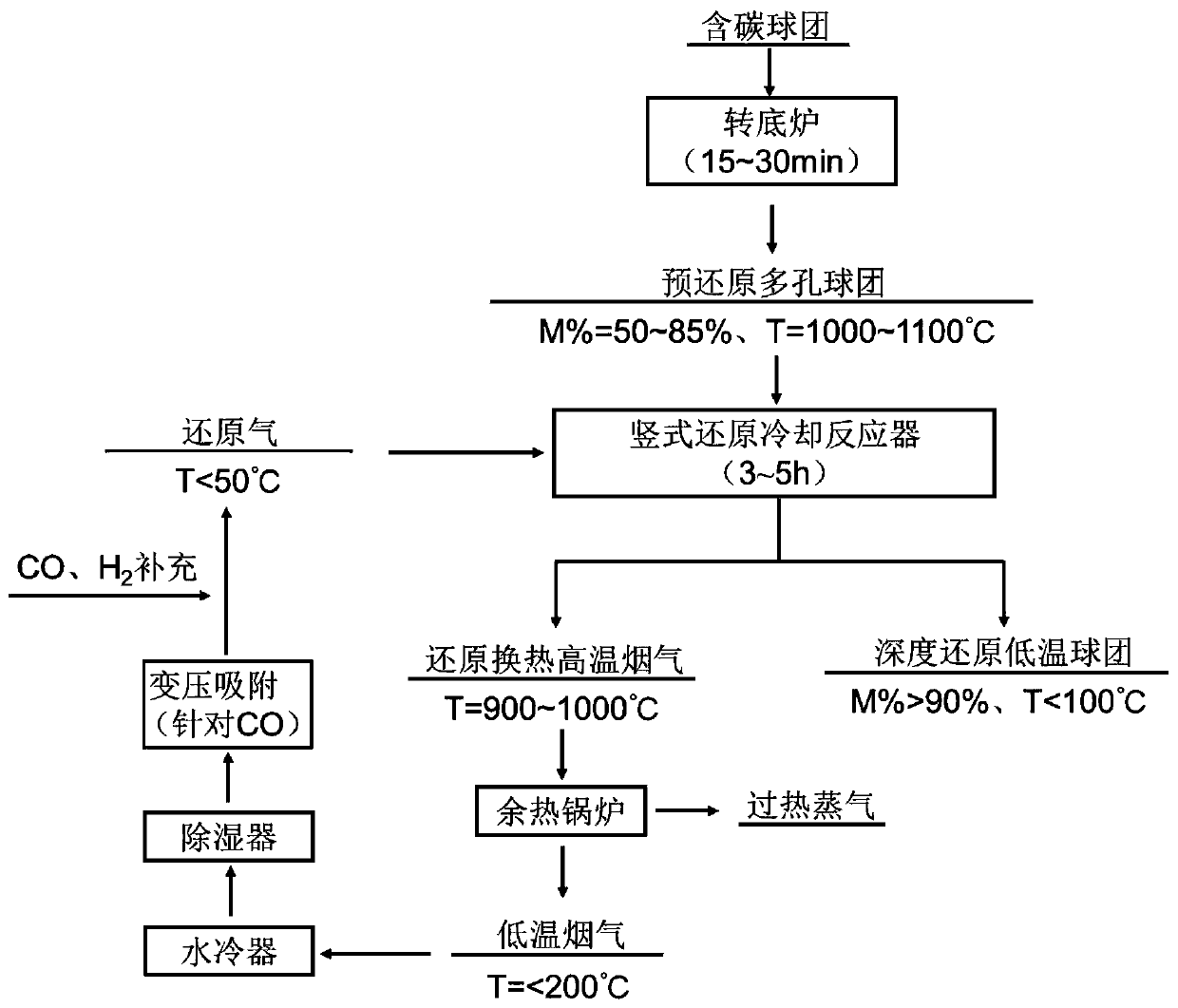

Iron-making method adopting carbothermal pre-reduction, gas-based deep reduction and synchronous cooling

A gas-based, carbon-thermal technology, applied in waste gas treatment, climate sustainability, sustainable manufacturing/processing, etc., can solve the complex gas source isolation control system, low carbon-thermal reduction degree of pellets, and slow gas-based reduction rate and other problems, to achieve the effect of promoting gas-based reduction rate, good internal porosity, and fast carbon-thermal pre-reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Guohai Sand Vanadium Titanium Magnetite, TFe content is 56%, chemical composition is shown in Table 1, ore powder particle size is less than 80 mesh.

[0045] The chemical composition (%) of table 1 sea sand vanadium-titanium magnetite

[0046] TF FeO Fe 2 o 3

TiO 2

V 2 o 5

SiO 2

CaO MgO Al 2 o 3

K Na Cl 56 21.85 56 10.67 0.76 4.29 0.72 3.18 4.12 <0.1

<0.1

<0.05

[0047] After uniformly mixing the vanadium-titanium magnetite and the binder, the carbon-containing pellets are prepared by a double-roller briquetting machine. 10kg of pellets were placed in a vertical reduction furnace and heated with H 2 It is a reducing gas, which is reduced at 900°C for 4 to 10 hours, and N is introduced after the reduction is completed. 2 Cool to 4h. The reduced pellets were crushed and ground to prepare powder samples, and the metallization rate of the samples was determined by chemical titration analysi...

Embodiment 2

[0050] Use the same vanadium-titanium magnetite raw material as above. After uniformly mixing the vanadium-titanium-magnetite, the binder, and the coal powder, the carbon-containing pellets are prepared by a double-roller briquetting machine, and the pellets have a C / O ratio of 1.2. The chemical composition of coal powder is shown in Table 2.

[0051] Table 2 Chemical composition of anthracite powder for reduction, %

[0052] composition(%) fixed carbon Volatile matter Ash S moisture anthracite 74.53 5.16 17.86 0.44 2.45

[0053] Put 10kg of carbon-containing pellets in an electrically heated small rotary hearth furnace for heating, and reduce them at 1250°C for 15-30 minutes to simulate the carbothermal reduction process of carbon-containing pellets. The reduced pellets were crushed and ground to prepare powder samples, and the metallization rate of the samples was determined by chemical titration analysis.

[0054] The experimental results...

Embodiment 3

[0056] In this example, the carbon-containing scout prepared in Example 1 is used for pre-reduction, deep reduction and synchronous cooling.

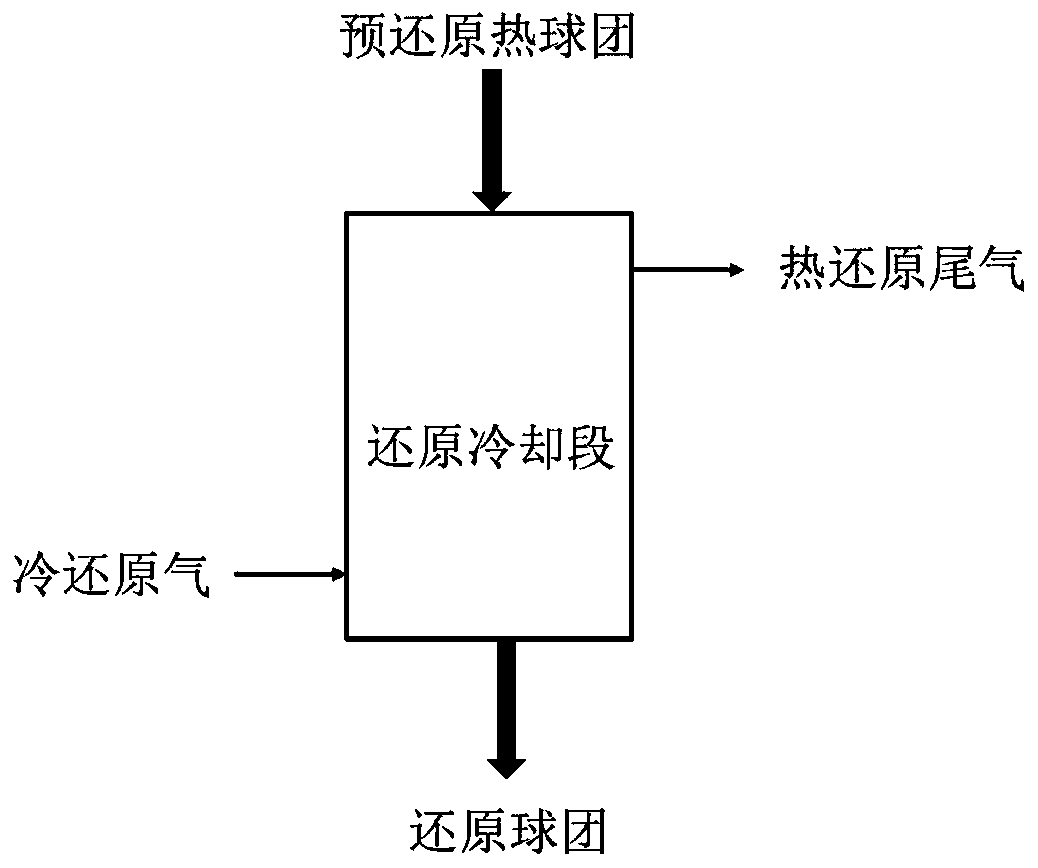

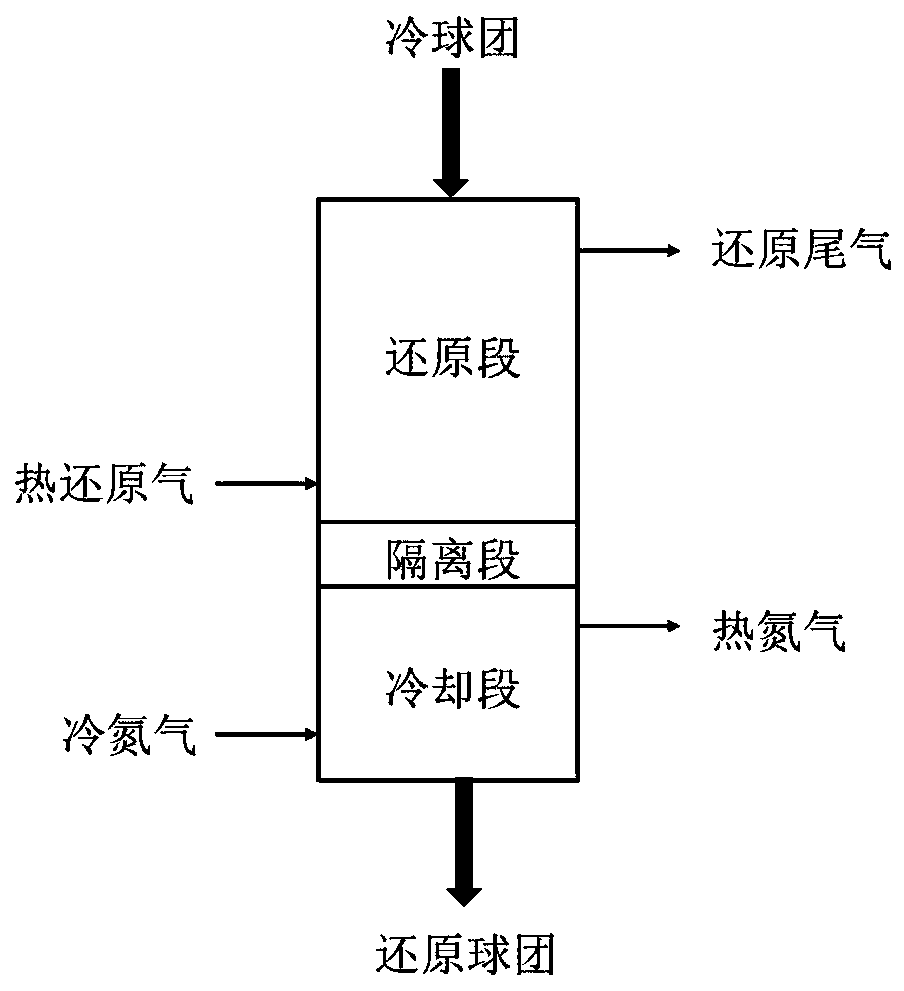

[0057] Place 10kg of carbon-containing pellets in a small rotary hearth furnace for heating, pre-reduce at 1250°C for 15 minutes and 20 minutes, stop heating after the reduction, and discharge the hot metallized pellets into the vertical reduction through the discharger after the reduction Cooler, into H 2 Reduction cooling 4h, H 2 The flow rate is 50L / min, H 2 The gas volume to pellet mass ratio is 1.2 Nm 3 / kg.

[0058] The high-temperature gas after reduction and heat exchange is heat exchanged by the waste heat boiler to prepare supersaturated steam for power generation. The temperature of the gas after heat exchange by the waste heat boiler is 200°C, and then cooled to below 50°C by a water cooler, and the cooled gas passes through a dehumidifier After dehumidification, return to the vertical reduction cooler for recycling, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com