Method for preparing high-quality reduced graphene through high-energy-pulse microwave rapid recovery

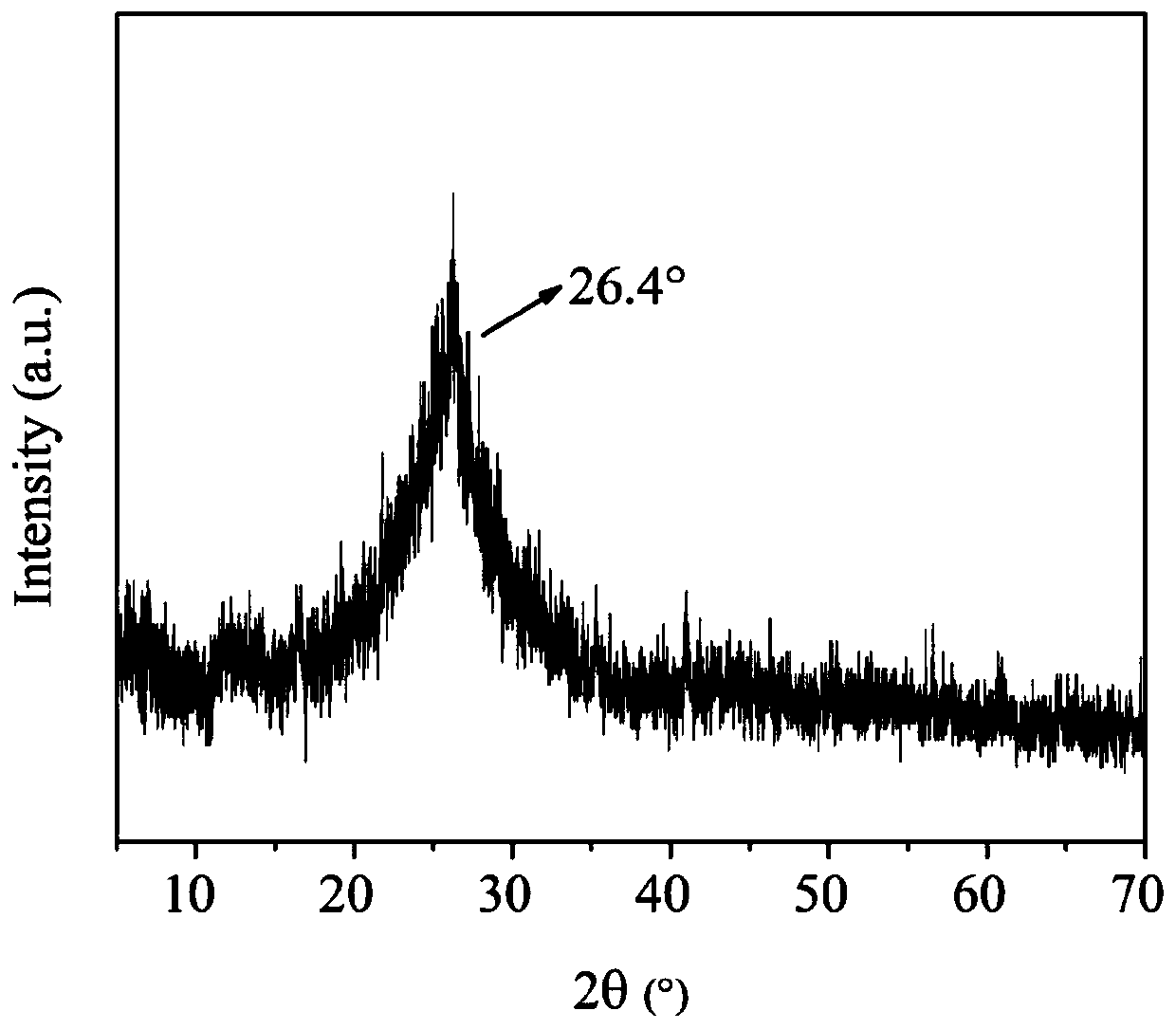

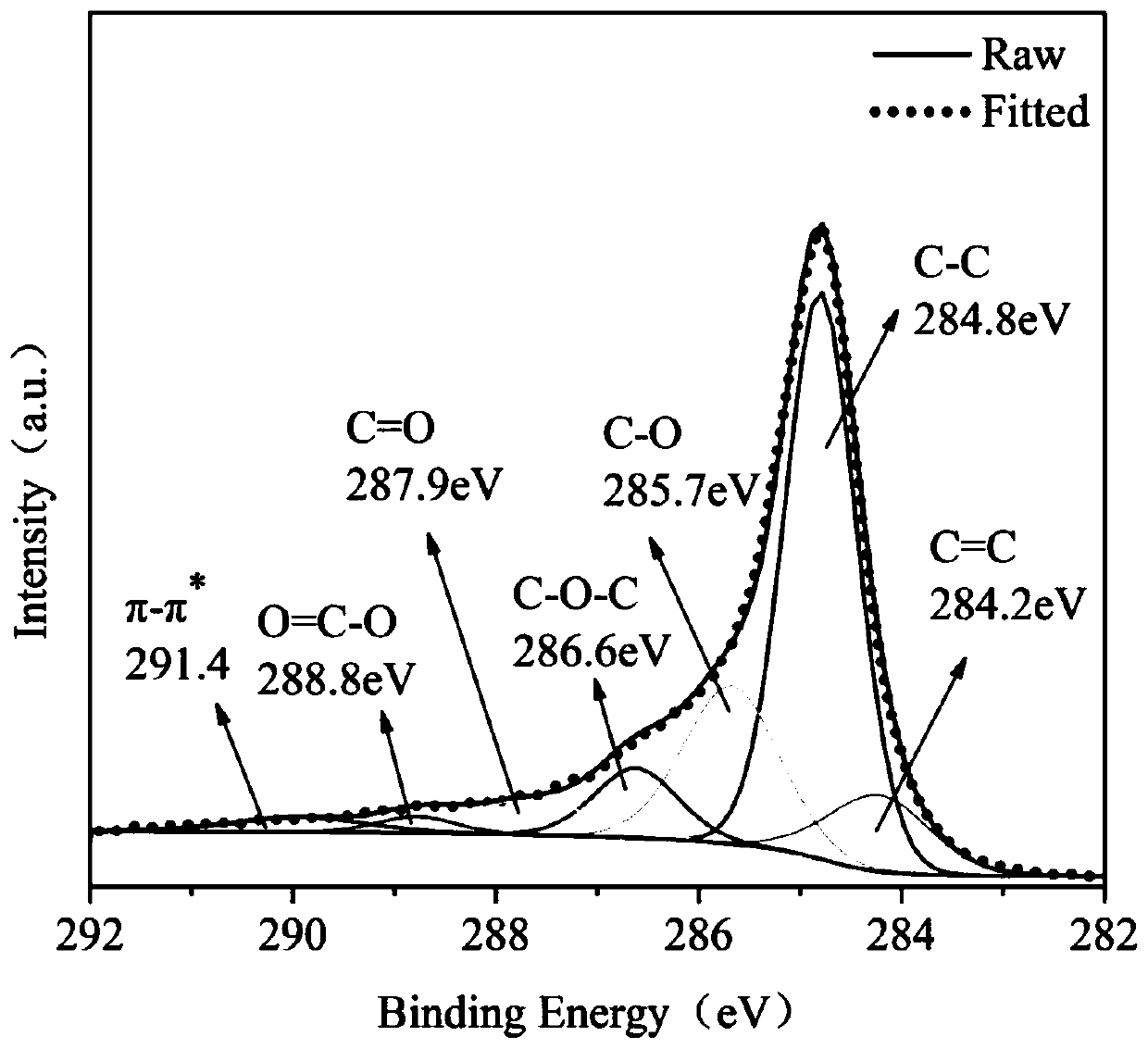

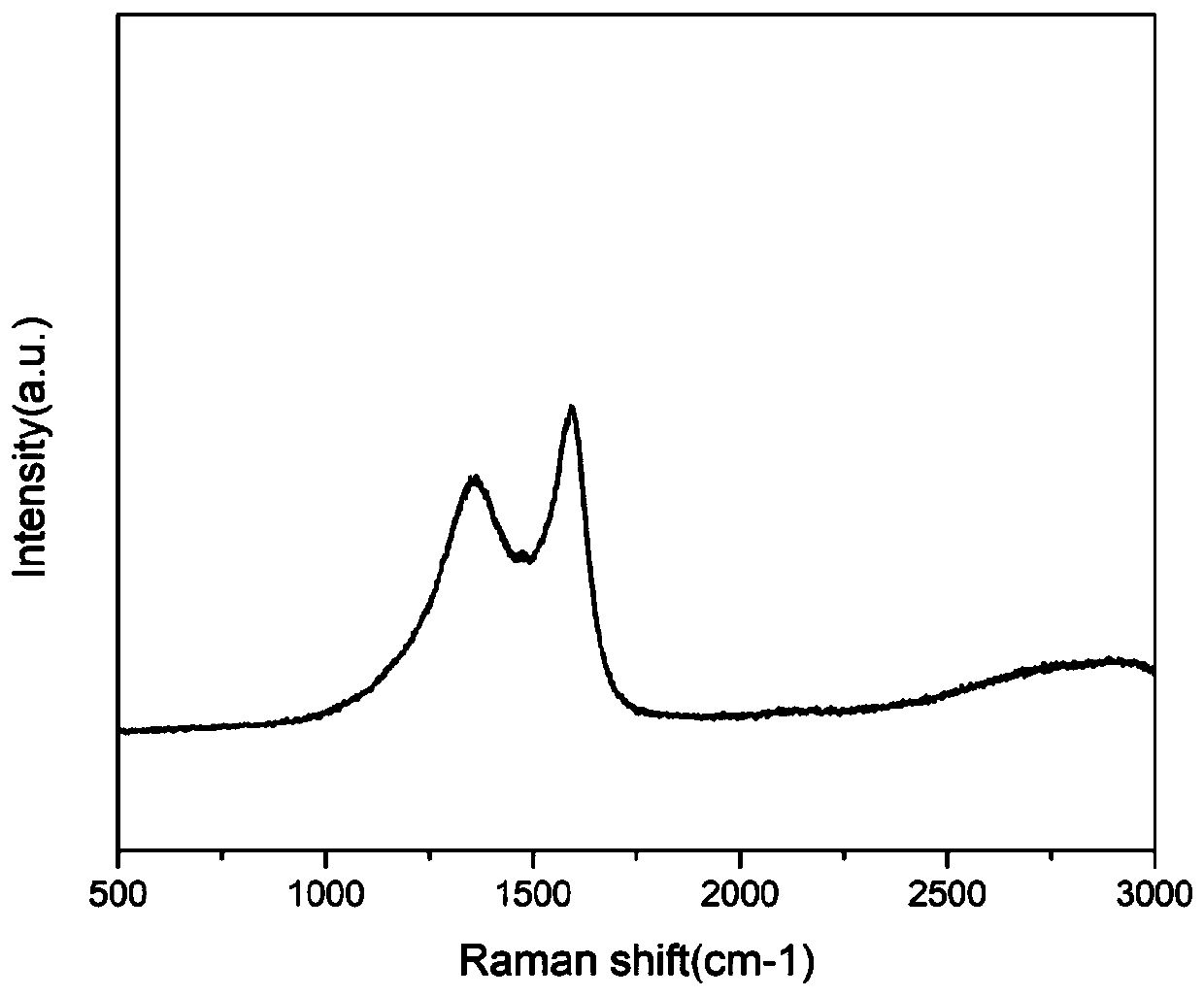

A high-energy pulse and graphene technology, applied in the graphene field, can solve the problems of many graphene defects and long processing time, and achieve the effect of simple operation, complete sheet structure and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 1g of flake graphite to 20mL of fuming nitric acid in an ice-water bath, then add 2mL of 30% hydrogen peroxide while stirring, react for 40min, wash with water, dry, and expand in a tube microwave oven with a power of 800w for 10s , to obtain expanded graphite.

[0027] Place a beaker containing 120ml of concentrated sulfuric acid with a mass fraction of 98% and 12ml of phosphoric acid with a mass fraction ≥ 50% in a low-temperature water bath at 0°C, add 1g of the obtained expanded graphite into the mixed acid solution, and stir magnetically for 30 minutes ; Secondly, according to the speed of 1g / h, 6g of potassium permanganate is slowly added to the above-mentioned mixed system, and the temperature of the reaction system is maintained at no more than 20°C (the addition of potassium permanganate should not be too fast, and can be added in small amounts and many times. ), continue the reaction at 0°C for 48h; then slowly add 400ml of dilute sulfuric acid at 0°C with...

Embodiment 2

[0034] Add 1g of flake graphite to 25mL of fuming nitric acid in an ice-water bath, then add 2mL of 30% hydrogen peroxide while stirring, react for 60min, wash with water, dry, and expand in a tube microwave oven with a power of 500w for 30s , to obtain expanded graphite.

[0035]Place a beaker containing 110ml of concentrated sulfuric acid with a mass fraction of 98% and 12ml of phosphoric acid with a mass fraction ≥ 50% in a low-temperature water bath at 0°C, add 1g of the obtained expanded graphite into the mixed acid solution, and stir magnetically for 45 minutes ; Secondly, according to the speed of 1g / h, 5g of potassium permanganate is slowly added to the above-mentioned mixed system, and the temperature of the reaction system is maintained at no more than 20°C (the addition of potassium permanganate should not be too fast, and can be added in small amounts and many times. ), continue the reaction at 0°C for 48h; then slowly add 400ml of dilute sulfuric acid at 0°C with ...

Embodiment 3

[0039] Add 1g of flake graphite to 25mL of fuming nitric acid in an ice-water bath, then add 2mL of 30% hydrogen peroxide while stirring, react for 60min, wash with water, dry, and expand for 15s in a tube microwave oven with a power of 800w , to obtain expanded graphite.

[0040] Place a beaker containing 90ml of concentrated sulfuric acid with a mass fraction of 98% and 12ml of phosphoric acid with a mass fraction ≥ 50% in a low-temperature water bath at 0°C, add 1g of the obtained expanded graphite into the mixed acid solution, and stir magnetically for 10 minutes ; Secondly, according to the speed of 1g / h, 4g of potassium permanganate is slowly added to the above-mentioned mixed system, and the temperature of the reaction system is maintained at no more than 10°C (the addition of potassium permanganate should not be too fast, and can be added in small amounts and multiple times. ), continue the reaction at 0°C for 48 hours; then slowly add 270ml of ice-dilute sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com