Method for detecting the magnetism of weakly-magnetic mineral

A detection method and weak magnetic technology, applied in the direction of magnetic performance measurement, etc., can solve the problems of lack of equipment and devices, high precision requirements for balances and ammeters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

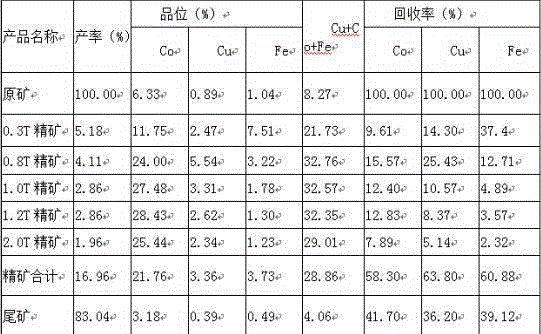

[0024] The raw ore containing Cu0.63%, Co5.14% and Fe0.73% is crushed and ground. After grinding, the -0.074mm ore accounts for 85% of all the ore. It is made into a slurry with a concentration of 25% and mixed well. The magnetic separation test with the background field strength from 0.3T to 2.0T is carried out with a small pair of extremely high gradient magnetic separators, and open-circuit sweeping is carried out at multiple field strengths to obtain concentrates and final tailings at various field strengths. The results of Example 1 are shown in Table 1.

[0025] Table 1 Example 1 result

[0026]

[0027] Mineral magnetic detection conclusion:

[0028] (1) The recovery rate of copper-cobalt-iron beneficiation using magnetic separation alone is low, all less than 65%.

[0029] (2) From the recovery rate of each field strength, it can be seen that the recovery rate of the target minerals copper and cobalt is significantly lower when the field strength is higher than 1....

Embodiment 2

[0033] For raw ore containing Cu1.64%, Co11.35%, and Fe2.37%, the raw ore is crushed, ground to -0.074mm to account for 85%, and mixed into a 25% concentration pulp. The magnetic separation test with the background field strength from 0.3T to 2.0T is carried out with a small pair of extremely high gradient magnetic separators, and open-circuit sweeping is carried out at multiple field strengths to obtain concentrates and final tailings at various field strengths. The results of Example 2 are shown in Table 2.

[0034] The result of table 2 embodiment 2

[0035]

[0036] Mineral magnetic detection conclusion:

[0037] (1) The recovery rate of copper-cobalt-iron beneficiation using magnetic separation alone is low, and the copper recovery rate is only 53%.

[0038] (2) From the recovery rate of each field strength, it can be seen that the recovery rate of copper and cobalt is significantly lower when the field strength is higher than 1.2T, so 1.2T can be used as the backgro...

Embodiment 3

[0042] For the raw ore containing Cu7.67%, Co5.93%, Fe6.19%, the raw ore is crushed, and the ore is ground to -0.074mm to account for 60%, 75%, and 90%, respectively, and the pulp with a concentration of 25% is prepared and mixed . The magnetic separation test with the background field strength from 0.1T to 2.0T is carried out with a small pair of extremely high gradient magnetic separators, and open-circuit sweeping is carried out at multiple field strengths to obtain concentrates and final tailings at various field strengths. The result of embodiment 3 is shown in table 3, table 4, table 5.

[0043] Table 3- 0.074mm accounted for 60% results

[0044]

[0045] Table 4-0.074mm accounts for 75% of the results

[0046]

[0047] Table 5-0.074mm accounts for 90% of the results

[0048]

[0049] Mineral magnetic detection conclusion:

[0050] (1) -0.074mm accounts for 60% and the recovery rate of copper, cobalt and iron for magnetic separation alone is relatively high,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com