Magnetic separation equipment and magnetic separation method for quartz sand

A technology of magnetic separation equipment and quartz sand, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of difficulty in purifying quartz sand, incomplete dispersion and increasing the volume of magnetic separation devices, etc., to achieve increased Magnetic separation effect, good magnetic separation effect, effect of improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

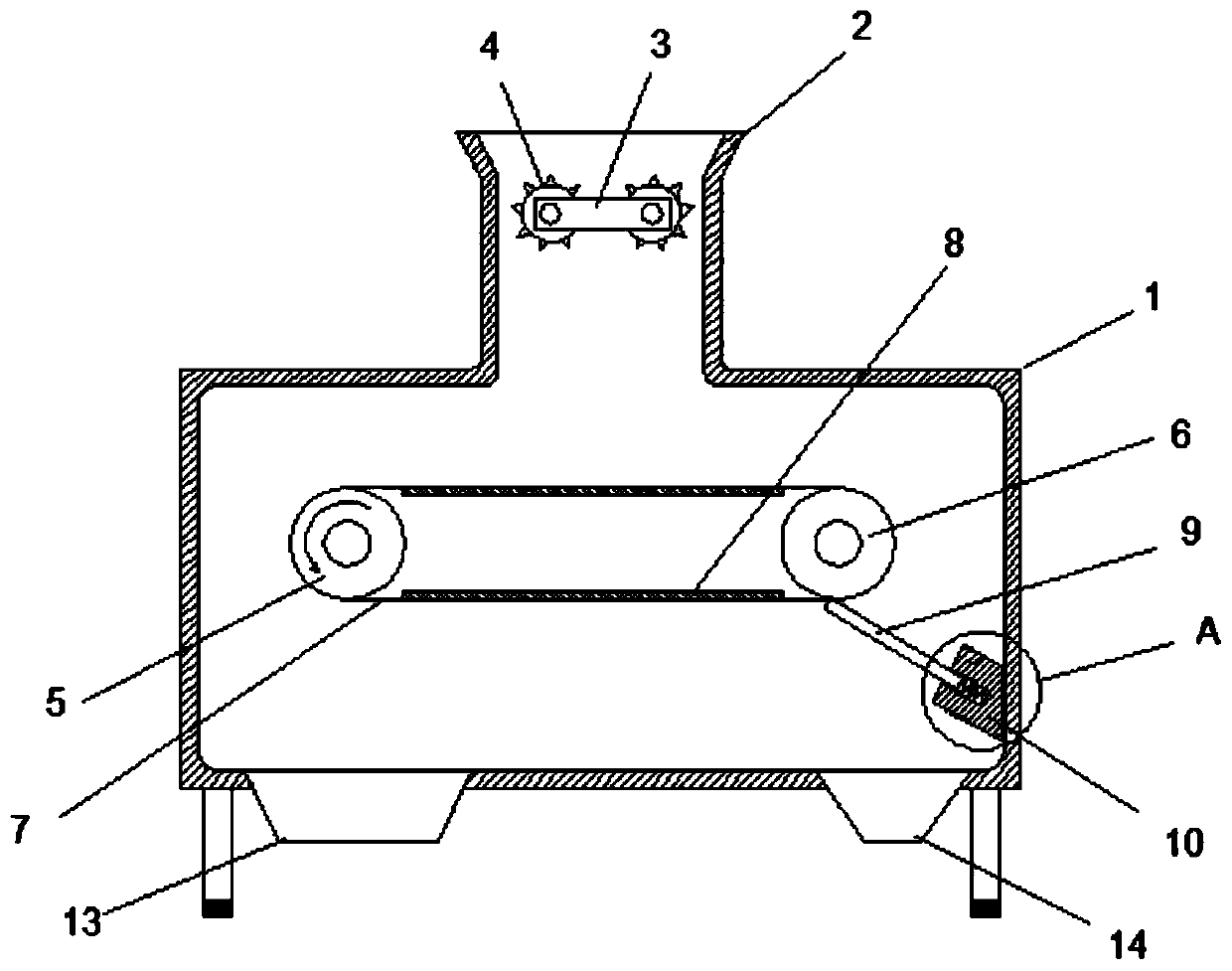

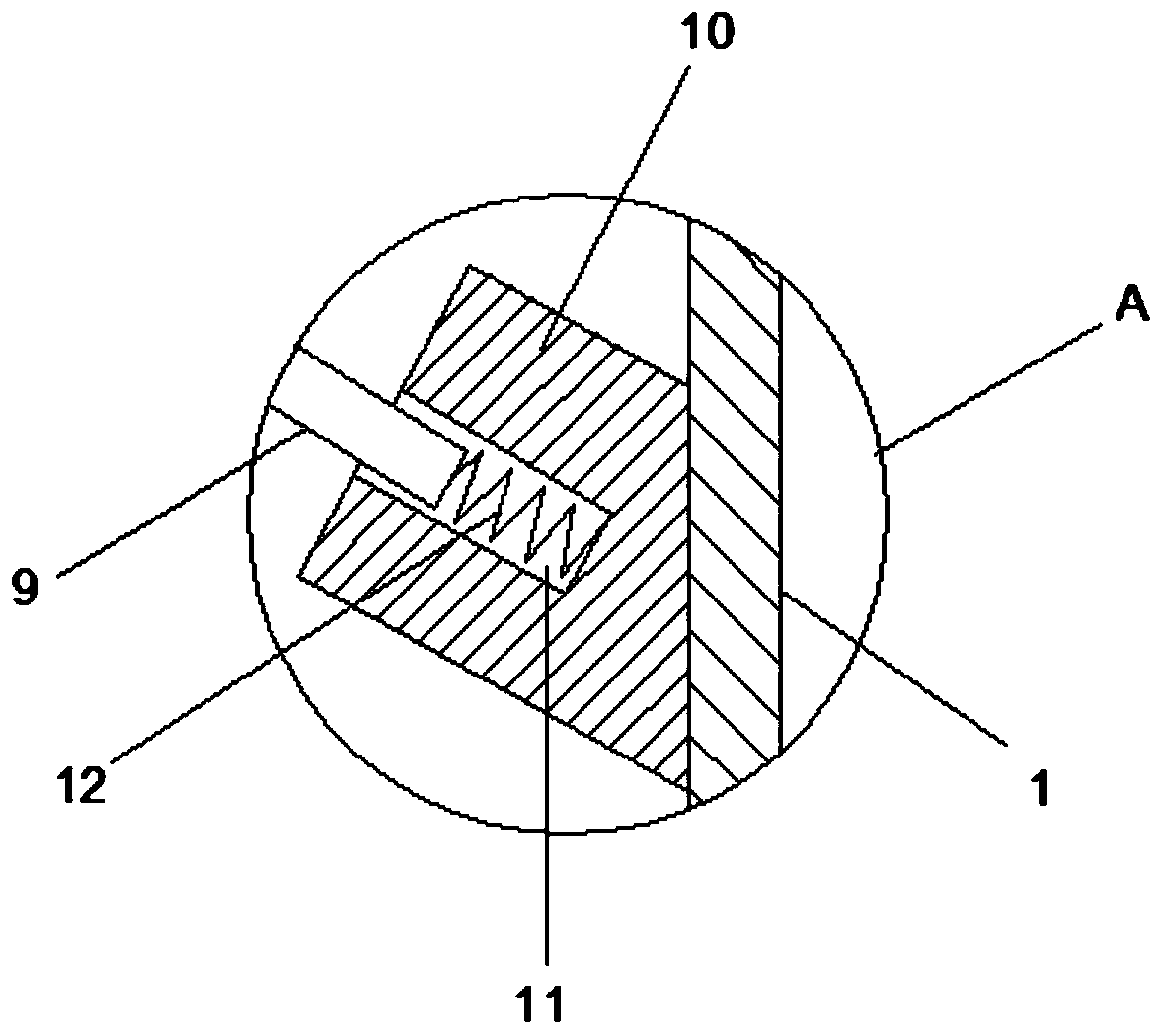

[0032] see Figure 1-2 A preferred embodiment of the magnetic separation equipment for quartz sand of the present invention shown, the magnetic separation equipment includes a magnetic separation bin 1 and a feed hopper 2 fixedly connected to the top of the magnetic separation bin 1, below the feed hopper 2 It communicates with the magnetic separation bin 1, so that the quartz sand that needs to be magnetically separated can be sent into the magnetic separation bin 1 through the feed hopper 2 for magnetic separation. In order to obtain a better magnetic separation effect, it is necessary to crush and pulverize the coarse quartz sand. For this reason, a crushing device is provided in the feed hopper 2. The crushing device includes a crushing motor 3 and a crushing roller 4, and the crushing roller There are two of 4, and they are relatively arranged in the feed hopper 2, and are connected with the crushing motor 3 outside the feed hopper 2, so that the quartz coarse sand enteri...

Embodiment approach 2

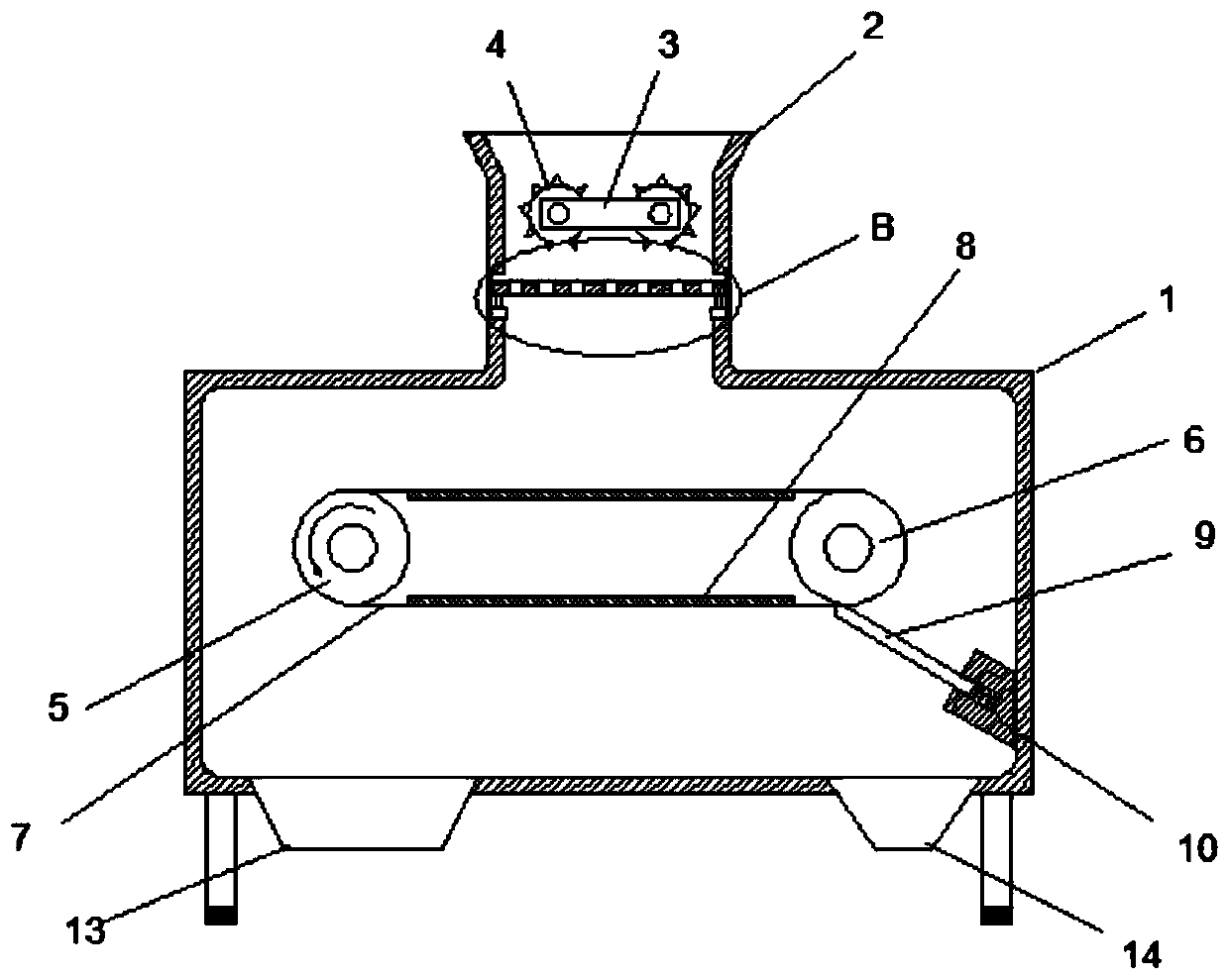

[0036] see Figure 3-4Shown is the second embodiment of the magnetic separation equipment for quartz sand of the present invention. The difference between this embodiment and the first embodiment is that in order to disperse the crushed quartz sand evenly on the conveyor belt, a A vibrating device is provided, and the vibrating device includes a vibrating motor 15 and a sieve plate 16 connected to the output shaft of the vibrating motor 15. The sieve plate 16 is evenly distributed with sieve holes 17, and the inner wall of the feed hopper 2 is provided with concave holes. groove 18, the vibration motor 15 is fixed on the bottom wall of the groove 18, and the sieve plate 16 is arranged in the groove 18, so that when the broken quartz sand needs to be dispersed, the vibration motor 15 is started The vibrating motor 15 drives the sieve plate 16 to vibrate. At this time, the quartz sand falling on the sieve plate 16 will be evenly dispersed on the sieve plate 16 due to the vibrati...

Embodiment approach 3

[0039] see Figure 5 The second embodiment of the magnetic separation equipment for quartz sand of the present invention shown, this embodiment is different from the second embodiment in that: a blower 19 is arranged on the left side of the magnetic scraping device, and the blower 19 is connected with Air blast head 20, said air blast head 20 is arranged inclined to the left, like this, can blow off the remaining quartz sand on the transmission belt 7 by air blast head 20, thereby improves the collection amount of quartz sand.

[0040] The working principle of the present invention is: when in use, the quartz sand is added into the feed hopper 2, first the coarse quartz sand is changed into fine quartz sand through the crushing treatment of the crushing device, and then evenly dispersed on the conveyor belt 7 under the action of the vibrating device. On the upper surface, the electromagnet 8 in the conveyor belt 7 attracts the magnetic material in the quartz sand. Under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com