High-efficiency complex ore-dressing device and ore dressing method

A compound and efficient technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of poor sorting effect, large floor space, long process flow, etc., to improve the strength and depth of the magnetic field , Reduce floor space and shorten the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

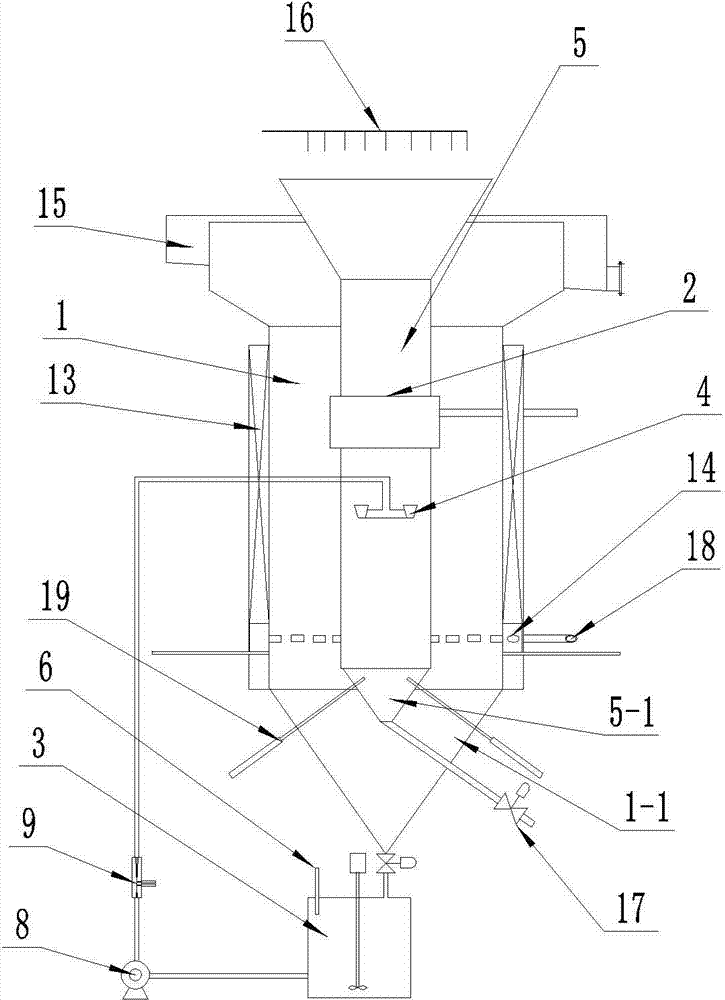

[0026] Example one, see attached figure 1 , The elutriator feeder 2 is arranged along the circumferential direction of the magnetic flotation column 5. The magnetic flotation column 5 is entirely located in the cavity of the washing machine 1, and a return mechanism is provided between the washing machine 1 and the magnetic flotation column 5. The return mechanism includes a stirring tank 3 with a dosing port 6, a slurry pump 8 and an air jet 9 connected in series. The discharge port of the elutriation machine 1 is connected with a stirring tank 3 arranged outside. The stirring tank 3 is provided with a dosing port 6, and the stirring tank 3 is equipped with a stirring device. The discharge port of the stirring tank 3 passes through a slurry pump 8 The air jet 9 is connected to the magnetic flotation column feeder 4 arranged in the magnetic flotation column 5. The feeding height of the magnetic flotation column feeder 4 is 1 / 3-1 / 2 of the height direction of the elutriator 1 to...

Embodiment 2

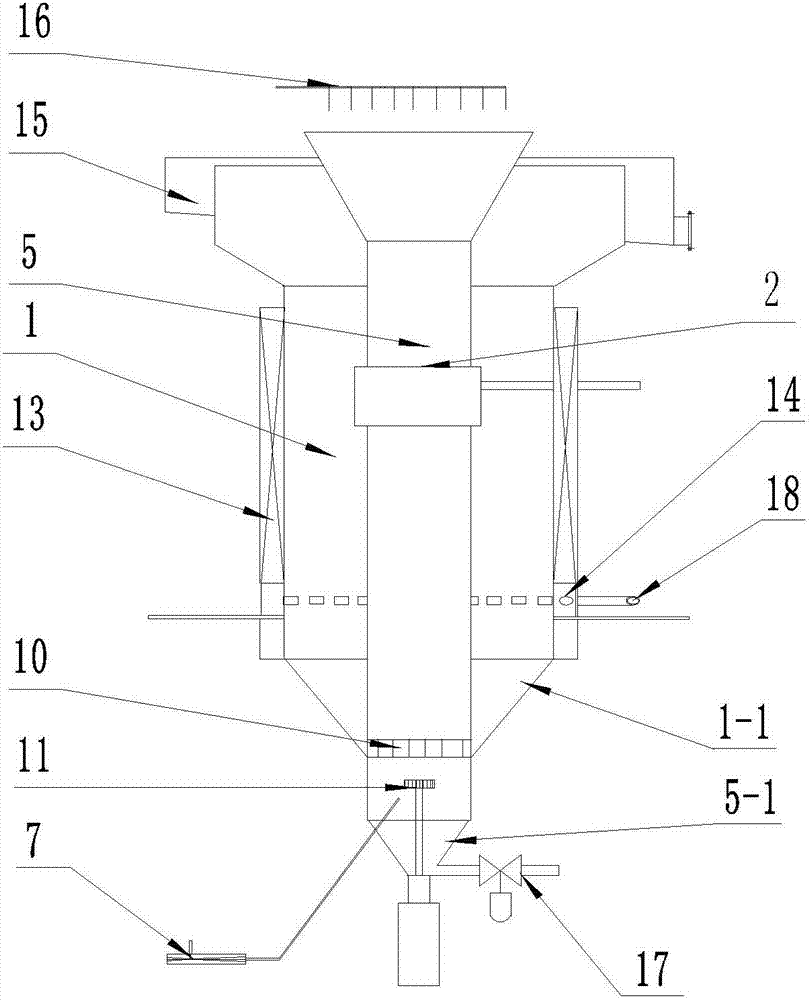

[0032] Example two, see attached figure 2 The difference from the structure in the first embodiment is that the magnetic flotation column 5 penetrates the washing machine 1 and the discharge port of the washing machine 1 is the slurry flow inlet 10 at the connection part of the magnetic flotation column 5 and the washing machine 1. The return mechanism is a coarse concentrate drop hopper 1-1 with a lower port positioned at the lower end of the magnetic flotation column 5, and a passage between the annular cavity of the elutriator 1 and the inner cavity of the magnetic flotation column 5 is formed by the coarse concentrate port 10. Inside the magnetic flotation column 5 and below the coarse concentrate port 10, a stirrer 11 and its driving mechanism are arranged. The lower section of the magnetic flotation column 5 and below the coarse concentrate port 10 are provided with a jet 7, and the jet 7 is provided with a gas injection port and Dosing port; at the end of the magnetic fl...

Embodiment 3

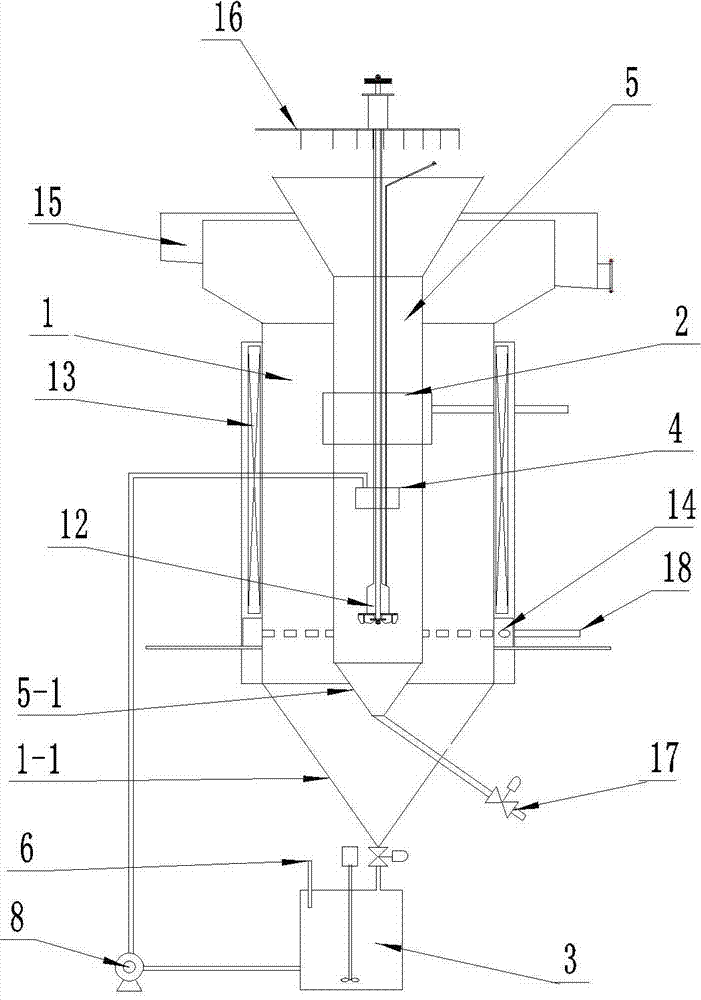

[0038] Example three, see attached image 3 The difference from the first embodiment is that the coarse concentrate washed by the washing machine 1 is directly fed into the magnetic flotation column 5 by the slurry pump 8. The return mechanism includes a slurry pump 8. The stirring device 12 pulverizes the air sent from the gas pipe to the lower end of the flotation column 5 into micro-bubbles and fully mixes with the slurry for mineralization. Preferably, the stirring device 12 is arranged coaxially with the magnetic flotation column 5.

[0039] When working, the specific beneficiation methods are as follows:

[0040] 1. The excitation coil 13 supplies magnetism to the washing machine 1, the water inlet pipe 18 feeds water to the washing machine 1 through the water feeder 14, and the slurry is evenly formed by the washing machine 1 and the magnetic flotation column 5 through the feeder 2 of the washing machine. The material is fed in the annular cavity. Under the combined action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com