Vertical magnetic separation method and vertical magnetic separation device

A magnetic separation device and vertical technology, applied in the field of magnetic separation, can solve the problems of affecting the magnetic separation effect and reducing the adsorption capacity of magnets for magnetic materials, and achieve the effects of improving the magnetic separation effect, low cost and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

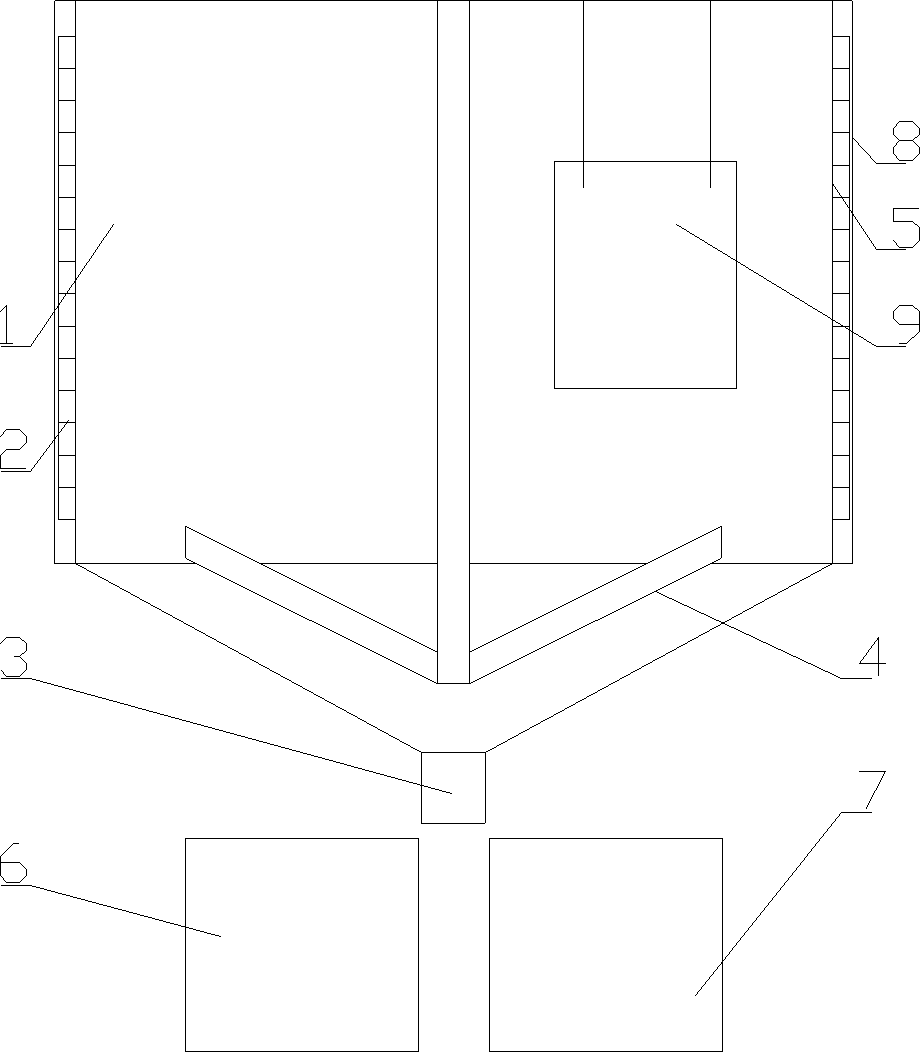

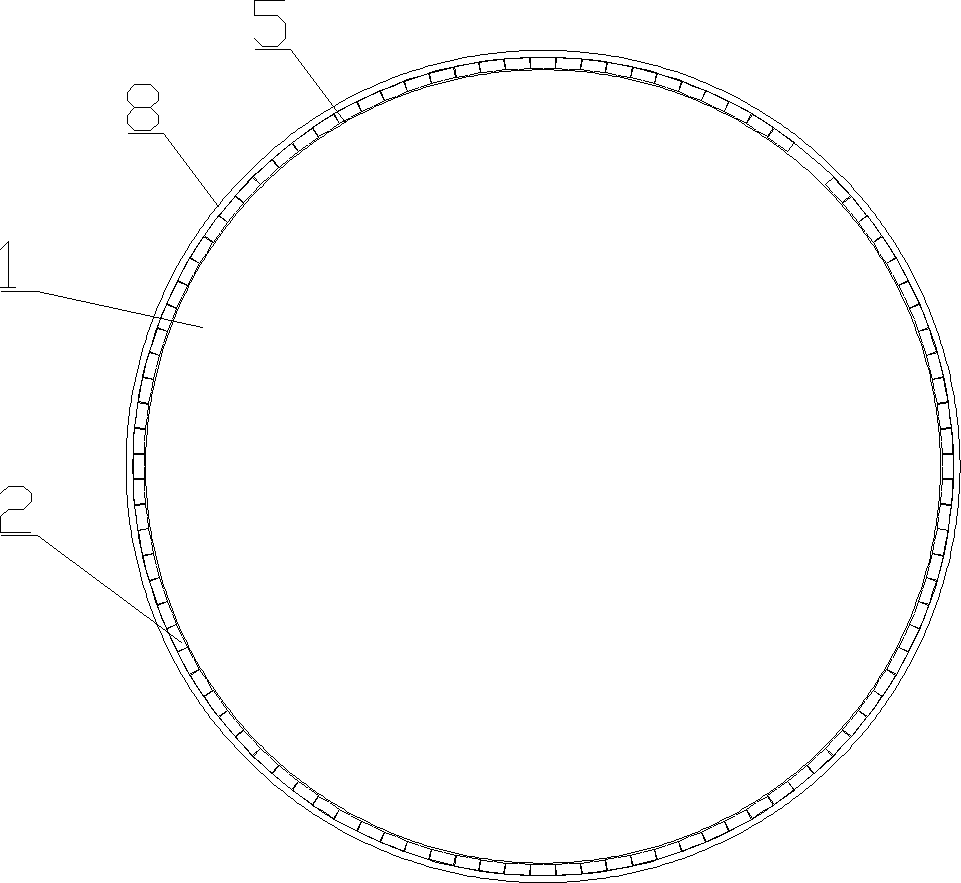

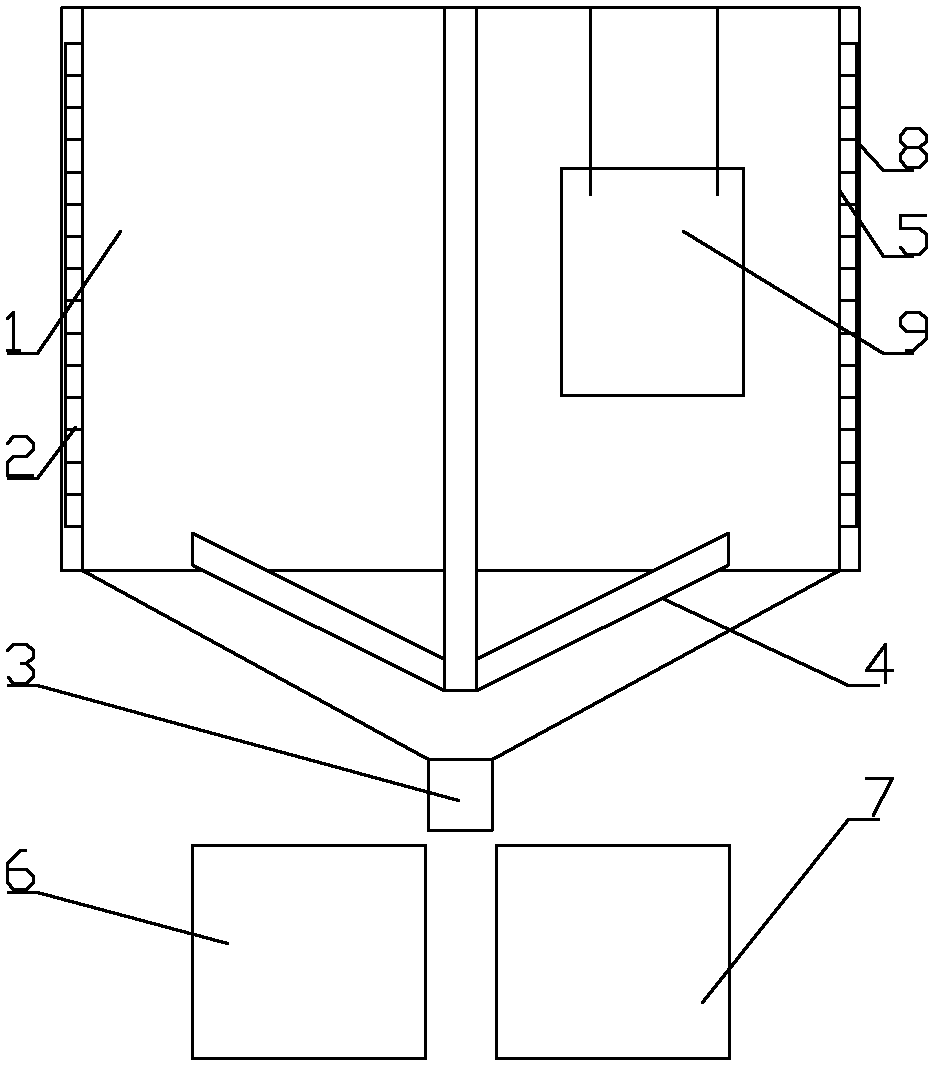

[0015] Embodiments of the invention. like figure 1 As shown, the cylinder 1 is made, the cylinder 1 is installed vertically, the magnet 2 is installed on the cylinder 1, the stirring blade 4 is installed in the cylinder 1, and the stirring blade 4 is connected to a transmission mechanism or a reducer.

[0016] The magnets 2 are arranged and installed on the cylinder body 1, and a protective layer 5 is arranged on the surface of the magnets 2 to improve the service life of the magnets 2. Moreover, the magnet 2 is usually assembled on the cylinder 1, there will be gaps between the magnets 2, and the magnetic material is adsorbed in the gap and it is difficult to clean. The protective layer 5 can protect the magnet 2 while avoiding the influence of the gap on the magnetic separation effect. Protective layer 5 can be antirust paint or thin stainless steel plate.

[0017] A discharge pipe 3 is installed at the lower part of the cylinder body 1, and the discharge pipe 3 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com