Preparation and applications of magnetic composite porous network adsorbing material

A porous network and adsorption material technology, which is applied in the field of preparation of magnetic composite porous network adsorption materials, can solve the problems of limited application and poor surface hydrophobicity, and achieve simplified pretreatment steps, high-efficiency adsorption capacity, good particle size uniformity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

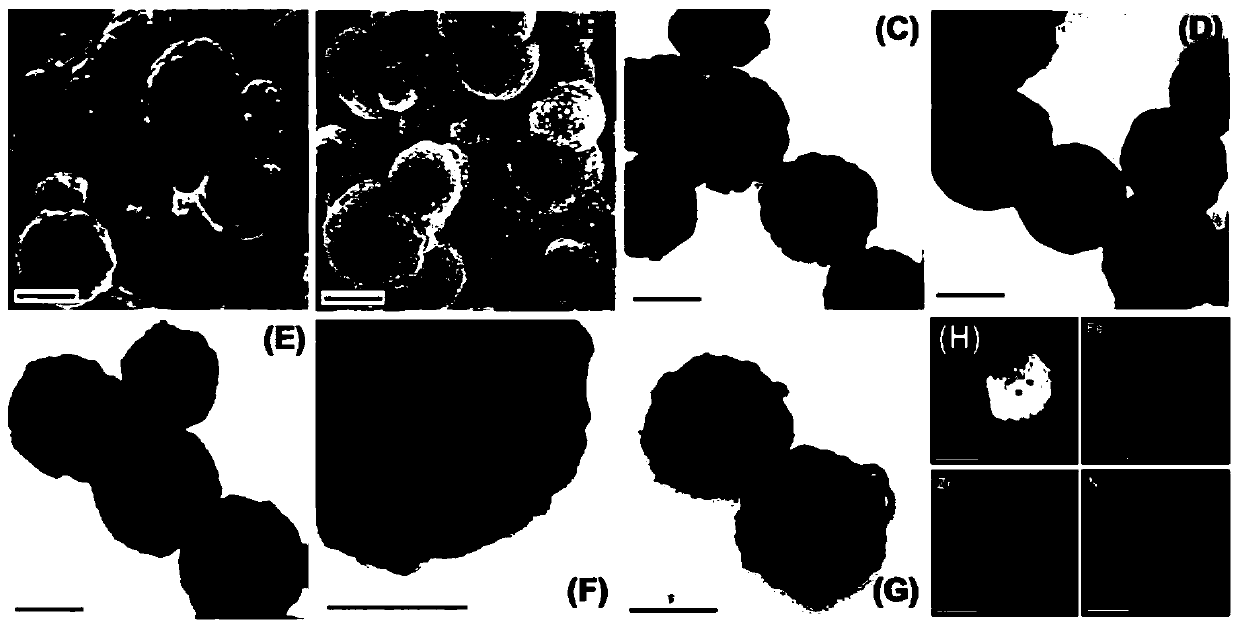

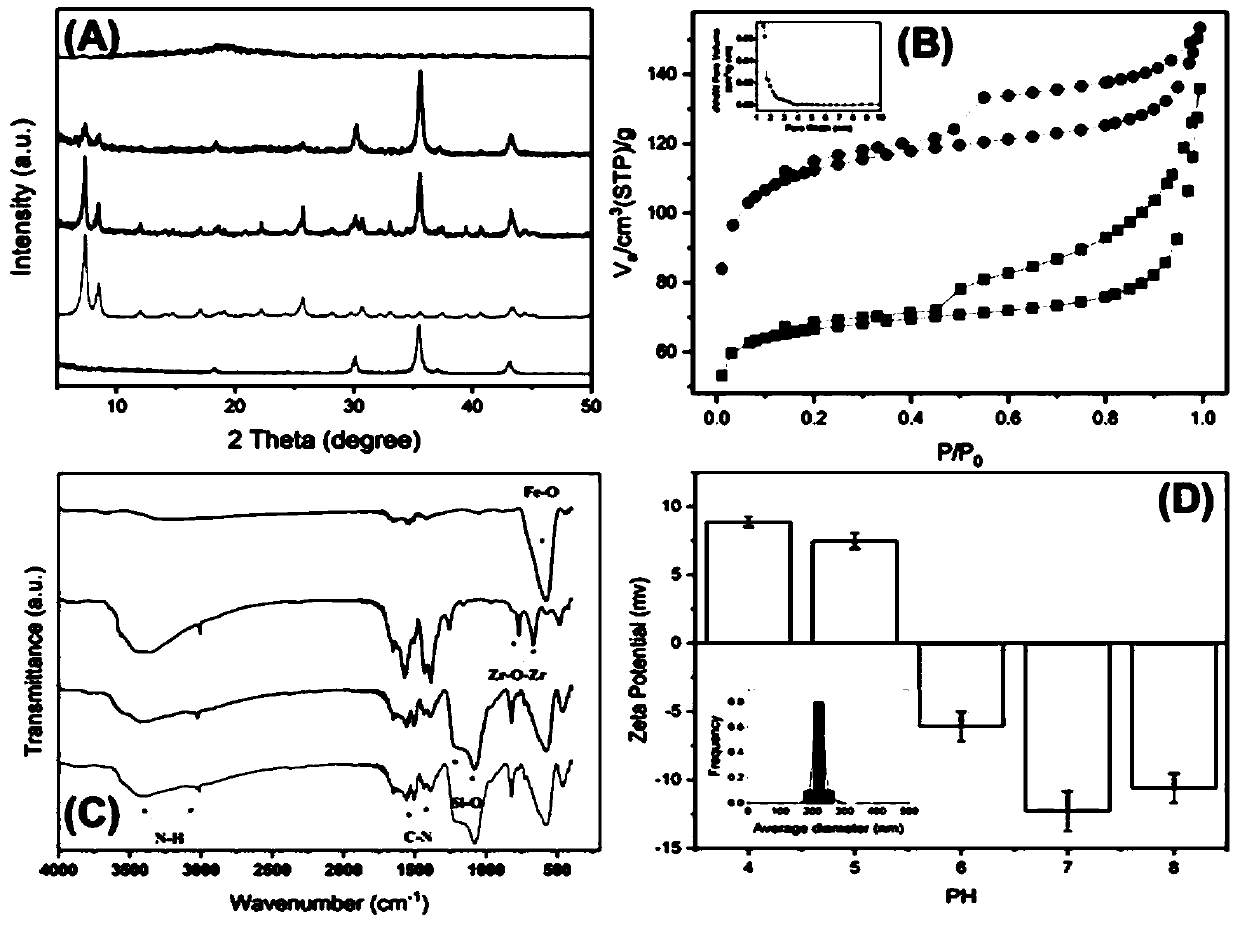

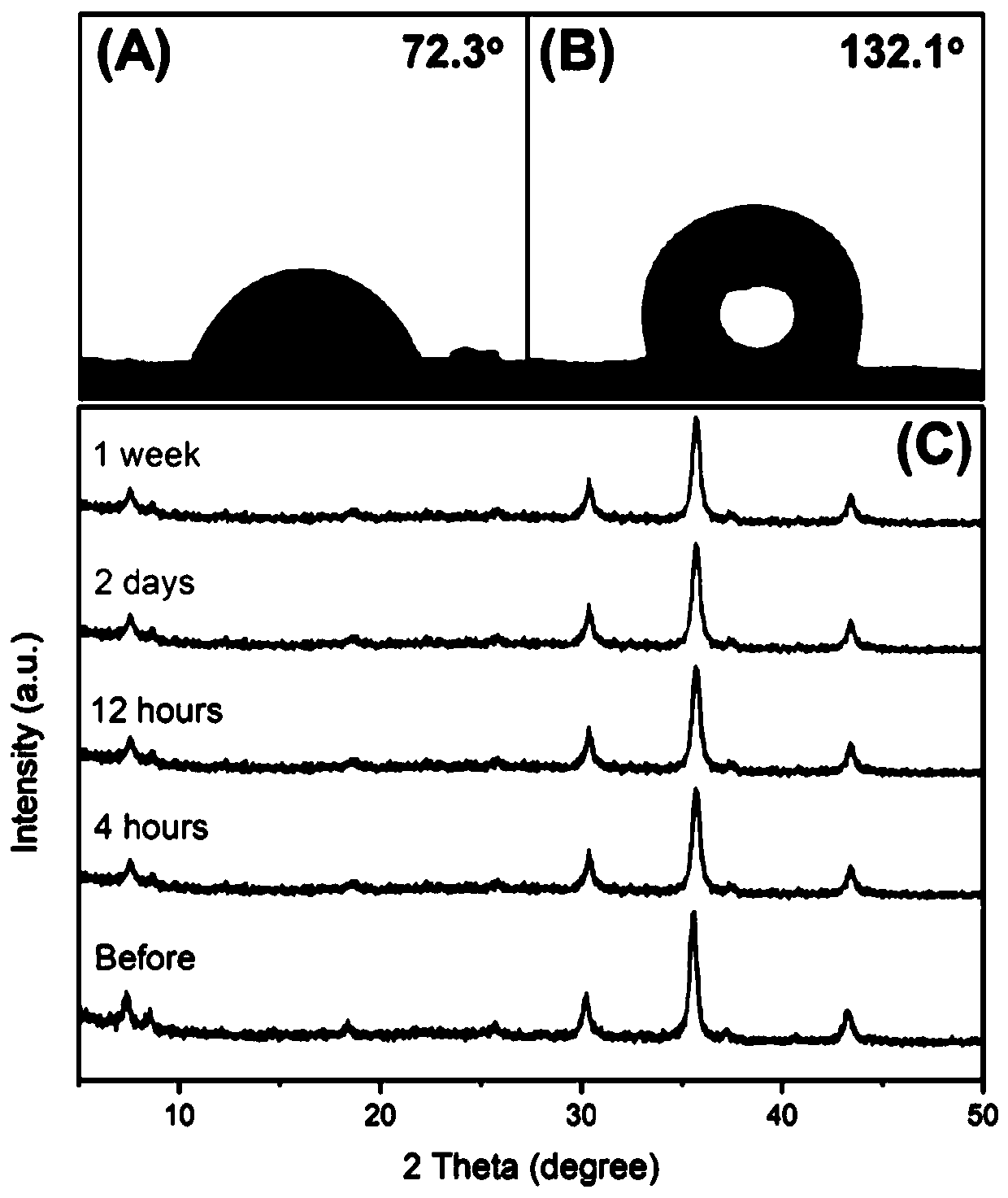

[0036] Preparation of a magnetic composite porous network adsorption material

[0037] (1) The in situ growth method is used to prepare magnetic porous organic framework materials with strong adsorption and large specific surface area.

[0038] Magnetic Fe 3 o 4 Preparation: 27g FeCl 3 ·6H 2 O. 57.5g of anhydrous sodium acetate and 500mL of ethylene glycol were mixed and stirred for 60 minutes, then transferred to a Teflon-lined hydrothermal reactor and heated at 200°C for 8 hours. After the reaction was completed and cooled to room temperature, it was washed 4 times with ultrapure water. Then vacuum-dried at 60° C. for 12 hours to collect a black magnetic powder product.

[0039] Magnetic Fe 3 o 4 @SiO 2 Preparation: Take 1.0g of the magnetic Fe obtained in the previous step 3 o 4 , add 200mL HCl (0.1mol / L), sonicate for 10min, and then rinse with ultrapure water for 3 times. Add 80mL ultrapure water, 320mL ethanol, 5mL ammonia water (25-28%), and sonicate for 10mi...

Embodiment 2

[0043] The material obtained in Example 1 was placed in the aflatoxin B1 solution, and after being adsorbed by shaking, it was separated with a magnet to realize the enrichment of the aflatoxin B1. Quantitative detection can be carried out in combination with high performance liquid chromatography.

Embodiment 3

[0045] The material obtained in Example 1 was placed in the aflatoxin B2 solution, and after being adsorbed by shaking, it was separated with a magnet to realize the enrichment of the aflatoxin B2. Quantitative detection can be carried out in combination with high performance liquid chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com