Method for removing iron titanium from non-metallic mineral raw materials

A non-metallic mineral and non-metallic technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of inability to effectively remove fine and weakly magnetic iron impurity minerals, expensive vibrating high-gradient magnetic separators, Weak magnetic minerals have poor processing effect, etc., to achieve better processing effect, save grinding cost, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

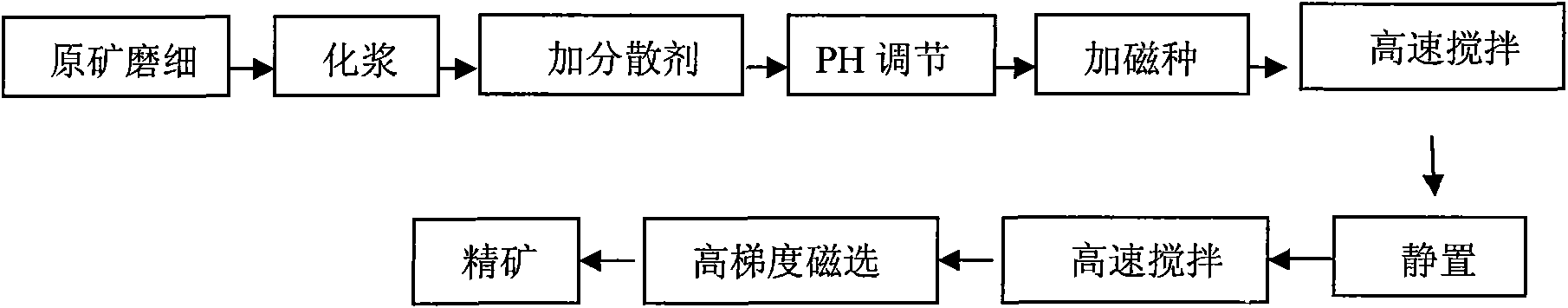

[0028] As shown in the process flow diagram of the present invention in Fig. 1, the non-metallic mineral used in the present embodiment is warm fire complete black mud, and its chemical composition is, SiO 2 : 62.05%, Al 2 o 3 : 30.95%, Fe 2 o 3 : 2.16%, TiO 2 : 0.64%, K 2 O: 2.76%, Na 2 O: 0.24%, MgO: 0.46%. Firstly grind the whole black mud raw ore with warm fire to 300 meshes, weigh 15Kg of ground fine material, put it into a larger container to make a slurry with a water content of 70% (weight percentage), put it into a stirring machine with an adjustable speed Stir for 10 minutes, add dissolved sodium pyrophosphate, account for 0.5% of the dry powder weight of warm fire black mud, add hydrochloric acid to adjust the pH to 6.5, stir for 10 minutes, add magnetic species Fe dispersed in water 3 o 4 , the amount of magnetic seed is 0.1% of the dry powder weight of warm fire whole black mud, the fineness of magnetic seed is 800 mesh sieve without sieve residue, 1700r / m...

Embodiment 2

[0030] First the whole black mud raw ore of warm fire in embodiment 1 is ground to 250 orders, weighs the fine material 15Kg that grinds in advance, is placed in a bigger container and is made into water content (percentage by weight) and is 50% ore slurry, puts Stir in an agitator with adjustable speed for 20 minutes, add dissolved sodium pyrophosphate, accounting for 1.0% of the dry powder weight of warm fire black mud, add sulfuric acid to adjust the pH to 6.5, stir for 15 minutes, add magnetic species Fe dispersed in water 3 o 4 , the amount of magnetic seed is 0.3% of the dry powder weight of warm fire whole black mud, the fineness of magnetic seed is 800 mesh sieve without sieve residue, 1700r / min rotating speed is stirred and mixed for about 5min, then left to stand for 12 hours, and diluted to The water content is 80%, and then the slurry is stirred at 1700r / min for 5 minutes, and then placed in two series-connected YCJ-II-B04 permanent magnet high-gradient magnetic se...

Embodiment 3

[0032] First the whole black mud raw ore of warm fire in embodiment 1 is ground to 300 orders, weighs the fine material 15Kg that grinds in advance, is placed in a larger container and is made into water content (percentage by weight) and is 60% ore slurry, puts Stir in an agitator with adjustable speed for 15 minutes, add dissolved sodium pyrophosphate, which accounts for 0.7% of the dry powder weight of warm fire whole black mud, add hydrochloric acid to adjust the pH to 6.3, stir for 12 minutes, add magnetic species Fe dispersed in water 3 o 4, the amount of magnetic seeds is 0.2% of the weight of the dry powder of warm fire all black mud, the fineness of the magnetic seeds is to pass 800 mesh sieve without sieve residue, stir and mix at 1700r / min speed for about 5 minutes, then let stand for 15 hours, and then dilute to The water content is 85%, and then the slurry is stirred at 1700r / min for 5 minutes, and then placed in two series-connected YCJ-II-B04 permanent magnet hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com