Efficient separation and recycling method for RO phase in steel slag

A technology for separation and recovery of steel slag, applied in cement production, etc., can solve the problems of limited mixing ratio, steel slag limitation, poor RO phase extraction effect, etc., achieve efficient separation and recovery, improve processing efficiency, and improve the effect of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As a preferred embodiment of the present invention

[0027] A method for efficiently separating and recovering RO phase in steel slag, characterized in that: comprising the following steps:

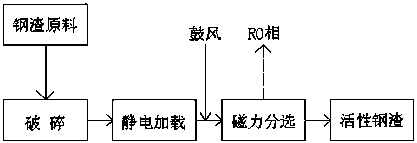

[0028] Step 1) Steel slag crushing: steel slag is used as the processing object, and it is crushed and screened, and the fine powder with a particle size of less than 100 mesh enters the next step of processing, and the larger particle size is returned to the crushing machine for further crushing. Step 2) Charge loading: Send the steel slag powder into the charge loading device, and in the device, a large amount of same-sex charges are generated through high-voltage discharge, and combined with the micro-powder particles, so that the micro-powder particles are loaded with same-sex charges and generate electrostatic repulsion between each other , to achieve ultra-dispersion treatment, and the treated steel slag powder enters the next step of treatment. Step 3) Separating the RO pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com