Integrated domestic solid waste treatment device

A processing device and living technology, applied in the direction of solid waste removal, transportation and packaging, chemical instruments and methods, etc., can solve the problems of increased workload, waste of recyclable materials, increased secondary pollution, etc. The effect of prolonging the contact time and reducing the work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

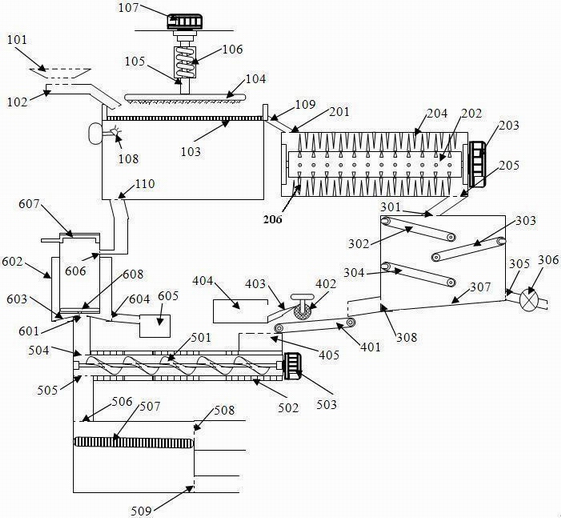

[0029] Further explanation in conjunction with accompanying drawings: figure 1 It is the domestic solid waste integrated treatment device of this embodiment, which includes extrusion separation components, crushing components, drying components, magnetic separation components, pyrolysis screening components and evaporation and condensation components.

[0030] Such as figure 1 As shown, the extrusion separation components include a solid waste inlet 101, an inlet guide plate 102, a perforated screen 103, an extrusion rotary disk 104, a telescopic rod 105, a spring chamber 106, a rotary disk drive motor 107, a blowback nozzle 108, an extrusion Pressure chamber outlet 109, sewage temporary storage tank ( figure 1 The chamber below the porous screen) and the extrusion chamber water outlet 110. Such as figure 1 As shown, the solid waste inlet is arranged above the inlet guide plate, one end of the inlet guide plate communicates with the solid waste inlet, and the other end is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com