Electromagnetic separator

A magnetic separator and electromagnetic technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory magnetic separation effect and poor performance of magnetic core, and achieve excellent magnetic separation effect, excellent electromagnetic separation effect, etc. performance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

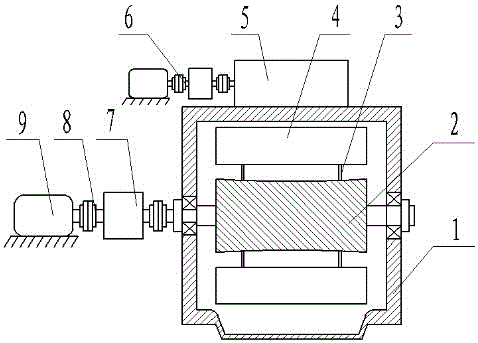

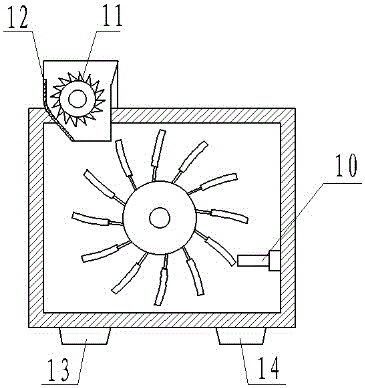

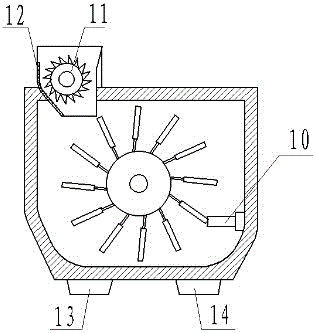

[0036]As shown in the accompanying drawings of the description, an electromagnetic magnetic separator includes a body 1, a driving device 6, a crushing device and a magnetic separation device; the outside of the body 1 is connected to the driving device 6, and the crushing device and magnetic Selection device; the crushing device is set in the feed port 5 on the body 1, the magnetic separation device includes a sorting device and a reverse current device 10; the sorting device is connected to the body 1 through a shaft. In the electromagnetic separator, the driving device 6 is provided with two groups, one group is connected with the crushing device, and the other group is connected with the sorting device. Since the driving speed of the magnetic separation device is different from the driving speed of the crushing device, the magnetic The driving speed of the selected equipment is relatively reduced, so in this scheme, the driving device is set into two groups, and each group ...

Embodiment 2

[0048] As shown in the accompanying drawings of the description, an electromagnetic magnetic separator includes a body 1, a driving device 6, a crushing device and a magnetic separation device; the outside of the body 1 is connected to the driving device 6, and the crushing device and magnetic Selection device; the crushing device is set in the feed port 5 on the body 1, the magnetic separation device includes a sorting device and a reverse current device 10; the sorting device is connected to the body 1 through a shaft. In the electromagnetic separator, the driving device 6 is provided with two groups, one group is connected with the crushing device, and the other group is connected with the sorting device. Since the driving speed of the magnetic separation device is different from the driving speed of the crushing device, the magnetic The driving speed of the selected equipment is relatively reduced, so in this scheme, the driving device is set into two groups, and each group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com