Process and system for co-production of quick lime and sulfur through gypsum reduction, oxidation and cyclic calcination

An oxidation cycle and process system technology, applied in the direction of sulfur preparation/purification, calcium/strontium/barium oxide/hydroxide, sulfur compounds, etc., can solve the problems of reducing the quality of quicklime and inability to co-produce various sulfur products , to achieve the effects of lowering the decomposition temperature, alleviating the shortage of sulfur resources, and reducing external dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

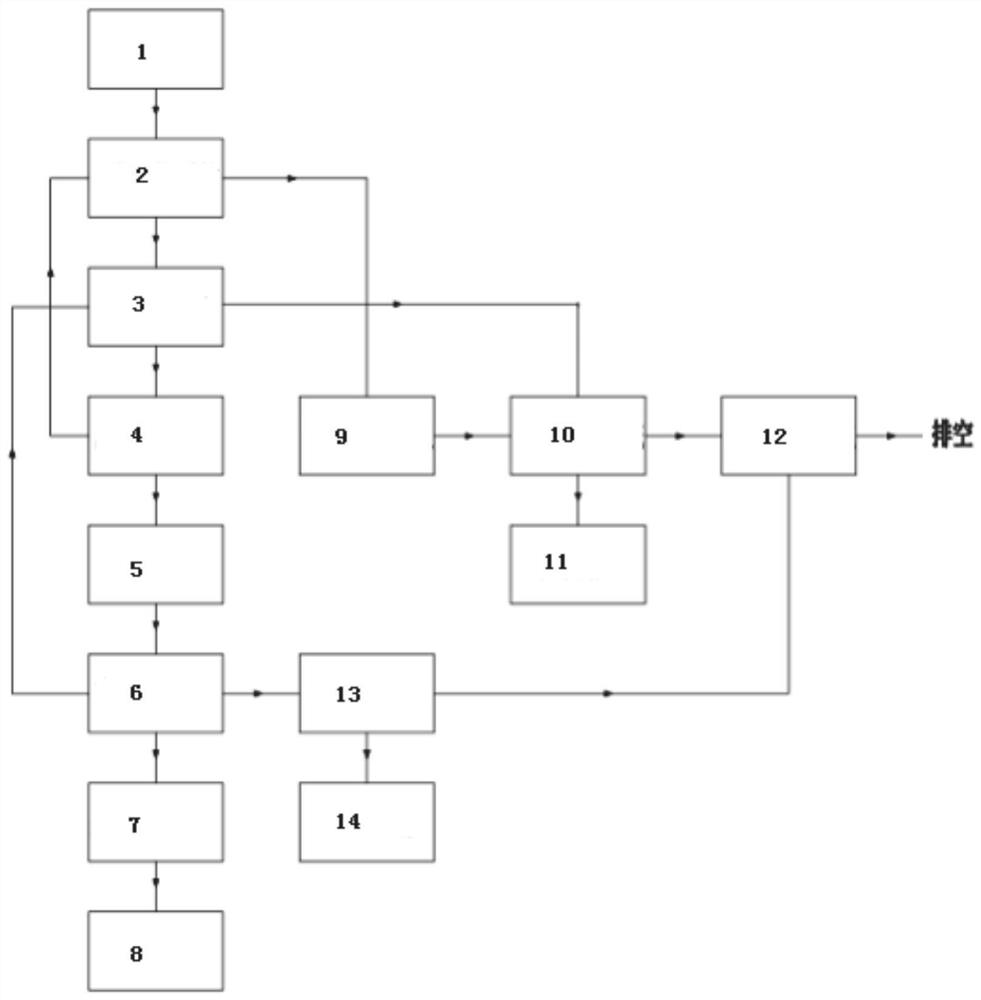

[0045] like figure 1 As shown, this embodiment provides a gypsum reduction-oxidation cyclic calcination system for joint production of lime and sulfur, including a gypsum storage bin 1 for storing gypsum, a preheating and drying system 2 connected in sequence, a reduction calciner 3, and a first high-temperature separator 4. Oxidation calciner 5, second high temperature separator 6, quicklime cooler 7 and quicklime storage bin 8, the gas phase outlet of the first high temperature separator 4 is connected to the gas phase inlet of the preheating drying system 2, one of the outlets of the second high temperature separator 6 Connect the reduction calciner inlet. Generally, the reaction between CaS and oxygen at high temperature also has parallel competing reactions. This embodiment limits the excess air ratio in the redox section. In the device disclosed in the present disclosure, a part of CaS reacts with oxygen to generate CaO and SO2 Another part of CaS reacts with oxygen to...

Embodiment 2

[0049] This embodiment provides a process for cyclic calcination of gypsum reduction and oxidation to generate lime and sulfur. The process is carried out in the system for cyclic calcination of gypsum reduction and oxidation to generate lime and sulfur described in Example 1.

[0050] Including the following steps:

[0051] The gypsum is stored in the gypsum storage bin 1, and is transported to the gypsum preheating and drying system 2 through the feeder to precisely control the feeding amount for preheating and drying. The high-temperature heat source comes from the calcination flue gas discharged from the reduction calciner 3; The temperature of the gypsum is 600-1050°C, first enters the reduction calciner 3, controls the reaction temperature 700-1200°C in the reduction calciner 3 and controls the air coefficient and excess air coefficient of the reducing gas, specifically, by controlling the reducing gas and the The mixing ratio of air and gas flow are precisely controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com