Continuous metal sheet winding apparatus

A technology of sheet metal and coiler, which is applied in coiling strips, thin material processing, transportation and packaging, etc. It can solve the problems of wasting energy and affecting production efficiency, and achieve the effects of energy saving, easy operation and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

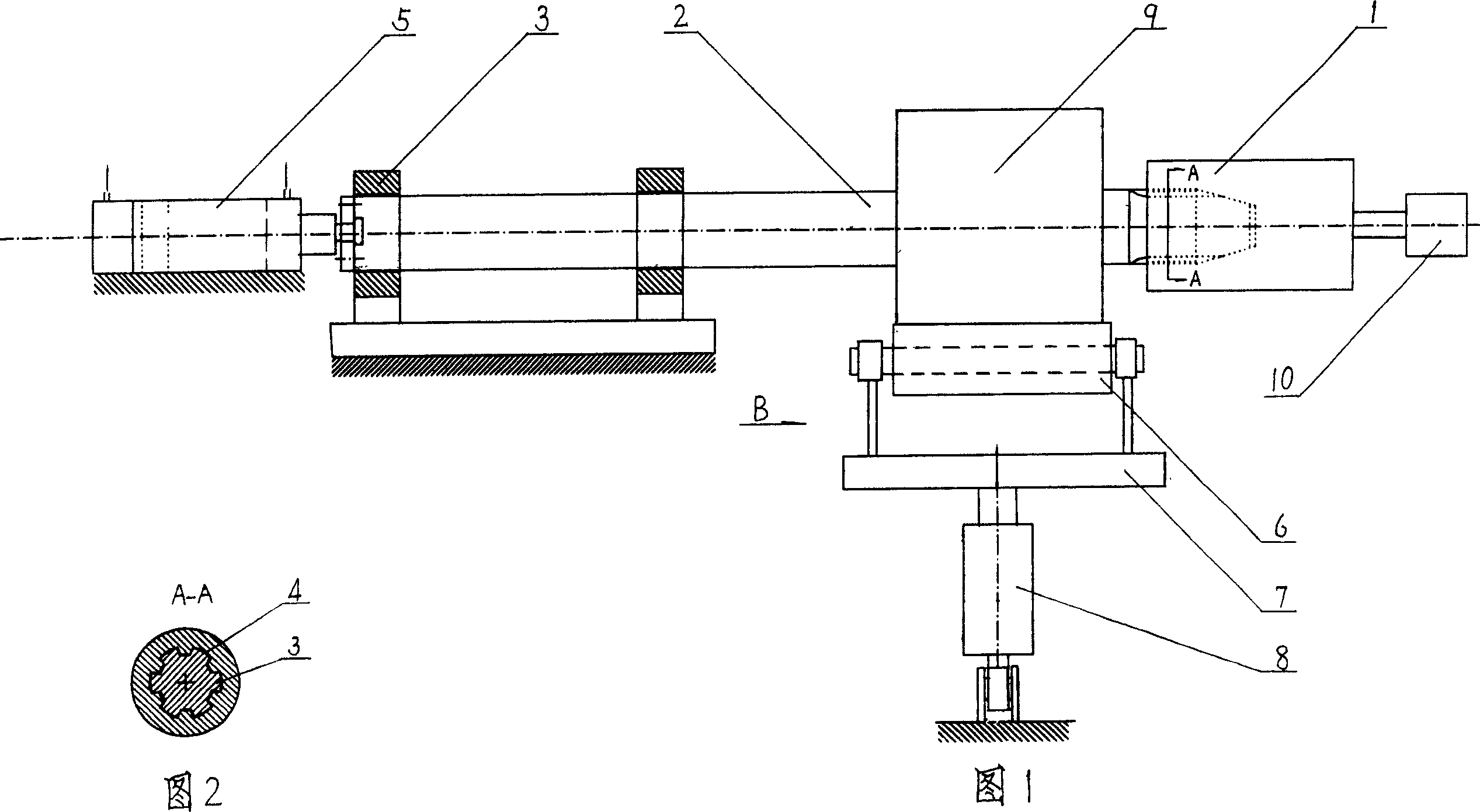

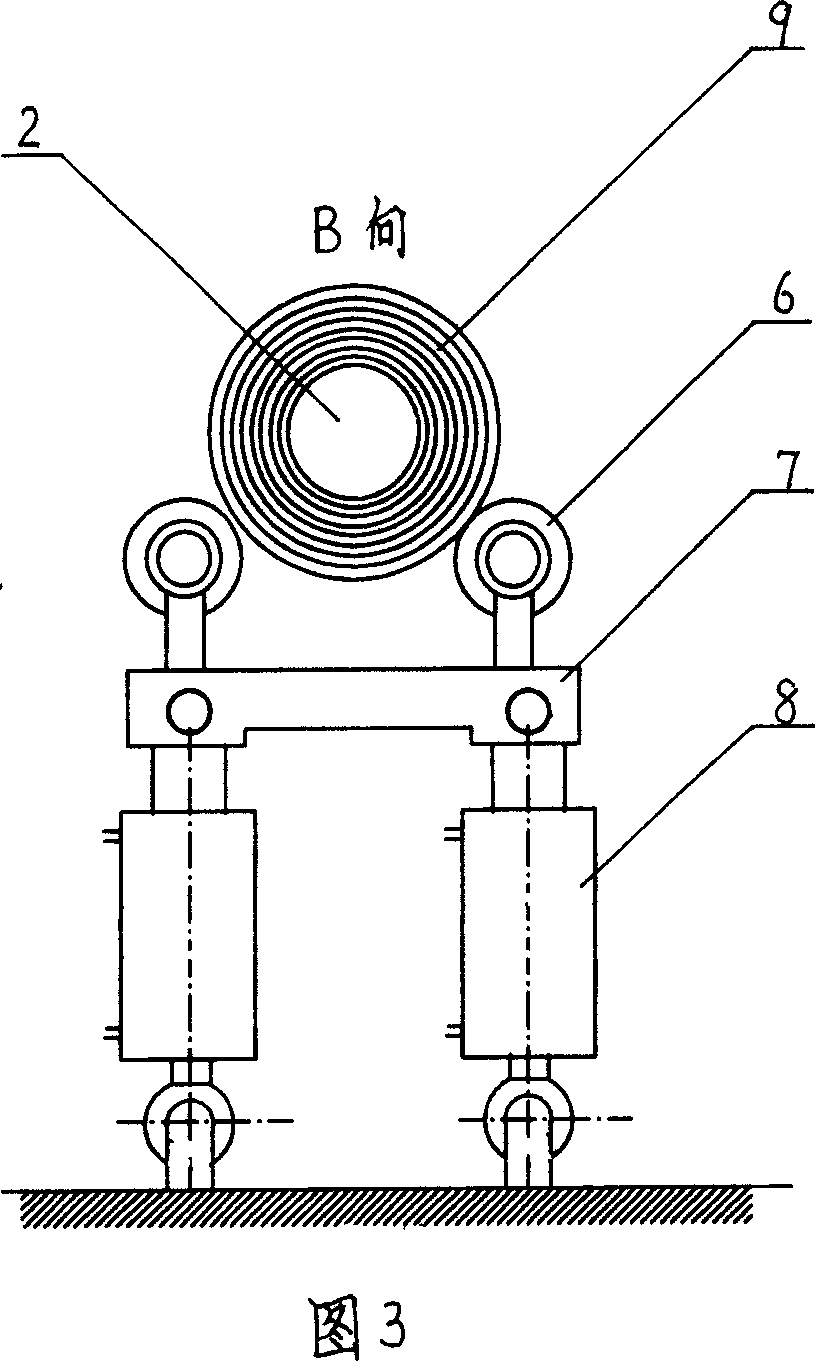

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention comprises a coiling roller 1 driven by a motor 10, located on one side of the coiling roller 1, and a coiling shaft 2 capable of magnetization and demagnetization is arranged on the same axis as the coiling roller 1, One end of the coiling shaft 2 facing the coiling roller 1 is provided with a connecting key 3, the connecting key 3 is engaged with the key groove 4 axially arranged in the center of the coiling roller 1, and the other end of the coiling shaft 2 is driven by a bracket 3 to work with it. The axially moving horizontal traction device 5 is connected; the rotation supporting device is arranged under the coiling shaft 2 .

[0015] The rotating support device includes at least two rollers 6 and a moving bracket 7, and the rollers 6 are installed on the bracket 7; the bracket 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com