Compensation enlarging value determination method

A compensation amount and determination method technology, which is applied in metal processing equipment, shipbuilding, naval vessels, etc., can solve the problems of waste of labor, impossibility of implementing precision control methods, waste of materials, etc., so as to increase annual output, reduce margin trimming and Effects of deformation correction work and shorter docking period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

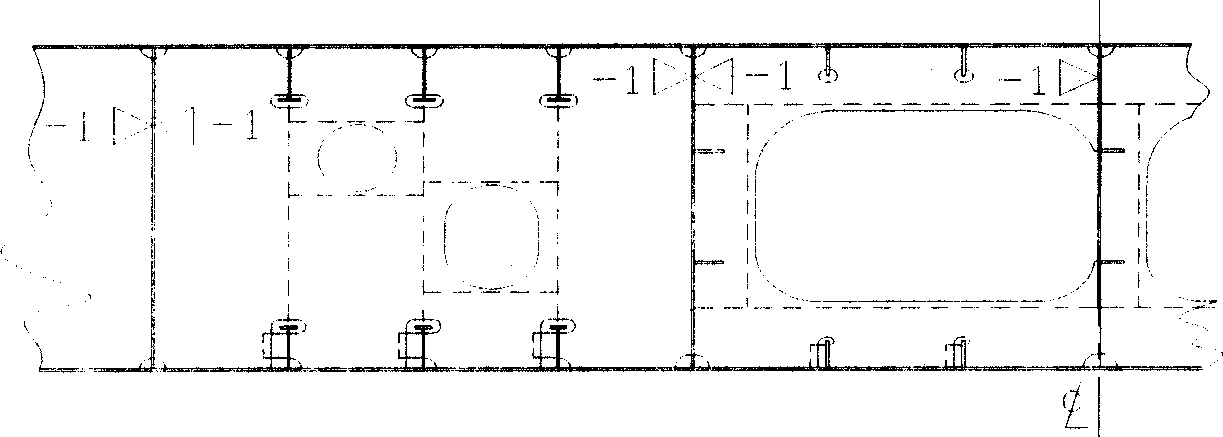

[0044] figure 1 What is shown is the addition and placement of the compensation amount for the assembly of the double bottom discontinuous ribs in the cargo hold and engine room of Embodiment 1.

[0045] The fixed value of the assembly compensation amount is added to the assembly compensation amount at the intermittent floor of the double bottom of the cargo hold and engine room, which is -1.

Embodiment 2

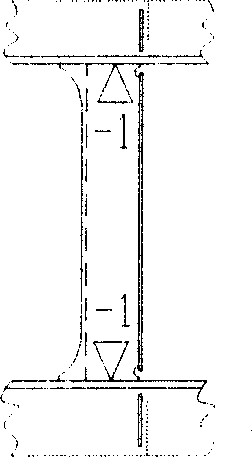

[0047] figure 2 What is shown is the addition and placement of the compensation amount for the assembly of rib reinforcements in Embodiment 2.

[0048] The assembly compensation amount of the rib reinforcement is added with the fixed value of the assembly compensation amount, which is -1.

Embodiment 3

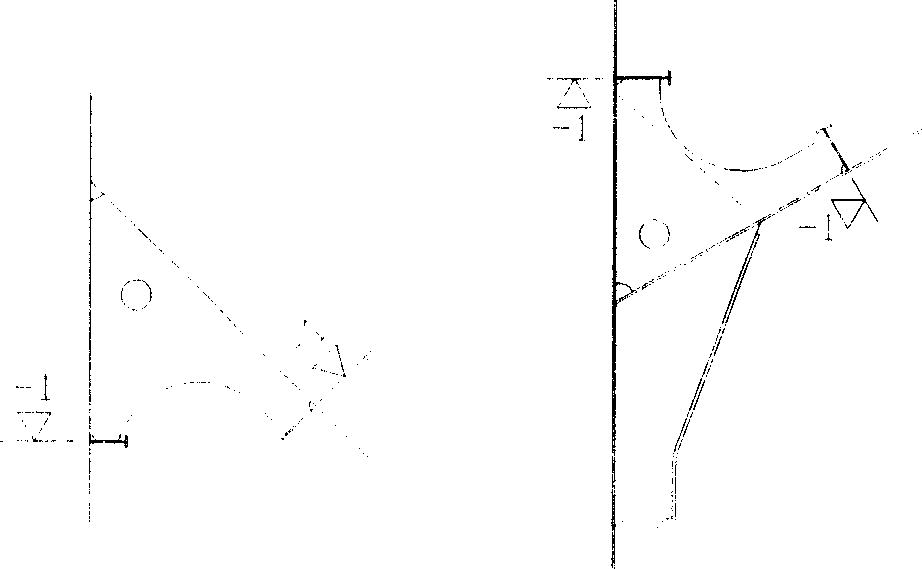

[0050] image 3 What is shown is the addition of compensation amount for bracket assembly in Example 3.

[0051] The bracket assembly compensation is added with the fixed value of the assembly compensation, which is -1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com