Immobilized porcine pancreatic lipase carrier, preparation method and application thereof

A technology of porcine pancreatic fat and enzyme carrier, applied in directions such as being fixed on/in an organic carrier, can solve the problems of complicated carrier preparation, harsh reaction conditions, difficult industrialization, etc. The effect of high annual output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment is the immobilized porcine pancreatic lipase carrier prepared by the following method:

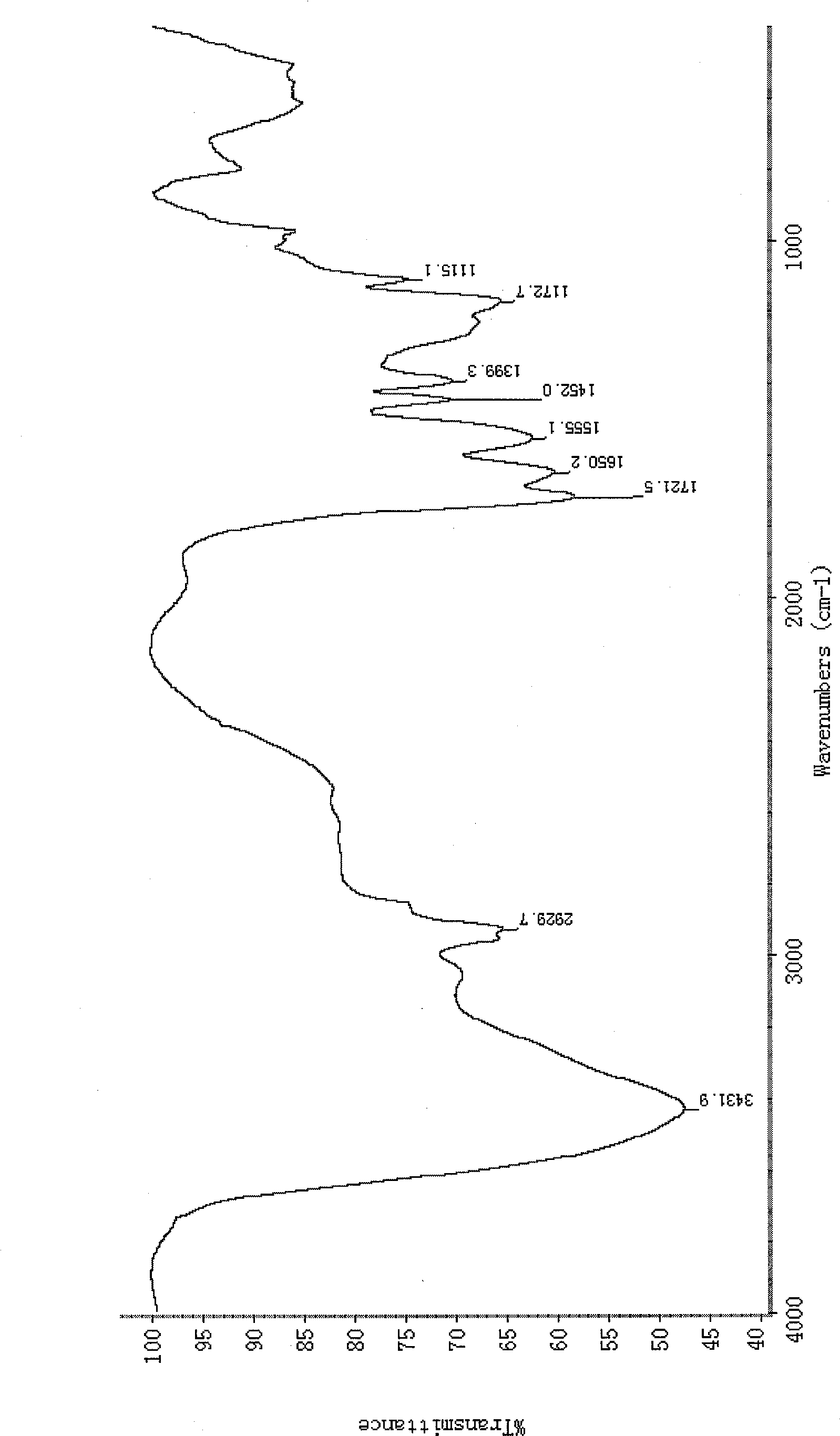

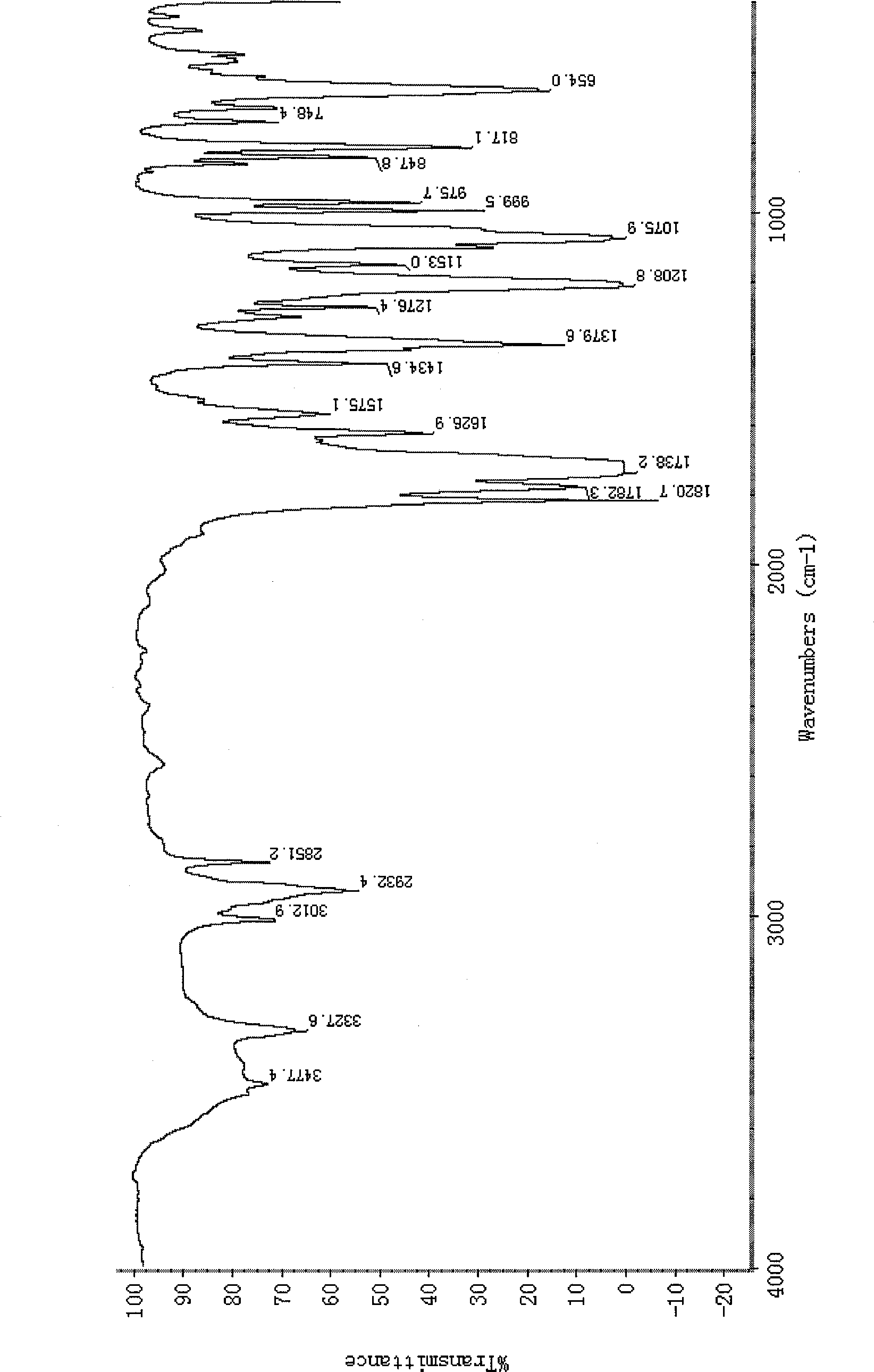

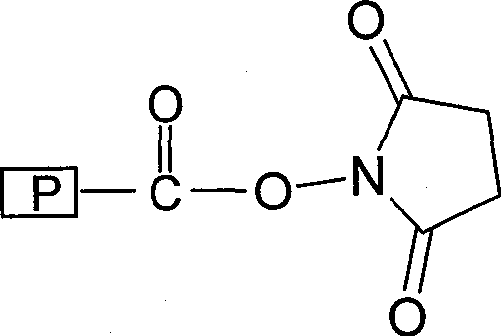

[0057] Surfactants Span (Span) 40 and Span80 are used as composite dispersants, kerosene is used as dispersed phase, acrylic acid (AA) is used as reactive monomer, and N,N'-methylenebisacrylamide (MBAA) is used as crosslinking agent , Ethylene glycol is the porogen, and the macroporous bead-shaped cross-linked polymer is prepared by reverse-phase suspension polymerization technology, and then activated by N-hydroxysuccinimide (NHS), to obtain the immobilized porcine pancreatic fat Enzyme carrier.

[0058] The raw materials used include:

[0059] Reactive monomer acrylic acid (AA) 5mL (about 5.3g),

[0060] Cross-linking agent N, N'-methylenebisacrylamide (MBAA) 2.1g (about 40% of AA quality),

[0061] Porogen ethylene glycol 4.0mL (about 4.5g, about 85% of AA mass),

[0062] The consumption ratio of dispersant Span40 and Span80 is adjusted to 5 with the HLB value...

Embodiment 2

[0085] This embodiment is the immobilized porcine pancreatic lipase carrier prepared by the following method:

[0086] Surfactants Span (Span) 40 and Span80 are used as composite dispersants, kerosene is used as dispersed phase, acrylic acid (AA) is used as reactive monomer, and N,N'-methylenebisacrylamide (MBAA) is used as crosslinking agent , Ethylene glycol is the porogen, and the macroporous bead-shaped cross-linked polymer is prepared by reverse-phase suspension polymerization technology, and then activated by N-hydroxysuccinimide (NHS), to obtain the immobilized porcine pancreatic fat Enzyme carrier.

[0087] The raw materials used include:

[0088] Reactive monomer acrylic acid (AA) 10mL (about 10.5g),

[0089] Cross-linking agent N, N'-methylenebisacrylamide (MBAA) 6.2g (about 59% of AA quality),

[0090] Porogen ethylene glycol 6.7mL (about 7.5g, about 71% of AA mass),

[0091] The consumption ratio of dispersant Span40 and Span80 is adjusted to 4.5 with the HLB v...

Embodiment 3

[0113] This embodiment is the immobilized porcine pancreatic lipase carrier prepared by the following method:

[0114] Surfactants Span (Span) 40 and Span80 are used as composite dispersants, kerosene is used as dispersed phase, acrylic acid (AA) is used as reactive monomer, and N,N'-methylenebisacrylamide (MBAA) is used as crosslinking agent , Ethylene glycol is the porogen, and the macroporous bead-shaped cross-linked polymer is prepared by reverse-phase suspension polymerization technology, and then activated by N-hydroxysuccinimide (NHS), to obtain the immobilized porcine pancreatic fat Enzyme carrier.

[0115] The raw materials used include:

[0116] Reactive monomer acrylic acid (AA) 2.5mL (about 2.6g),

[0117] Cross-linking agent N, N'-methylenebisacrylamide (MBAA) 1.3g (about 50% of AA quality),

[0118] Porogen ethylene glycol 2.3mL (about 2.6g, about 100% of AA mass),

[0119] The consumption ratio of dispersant Span40 and Span80 is adjusted to 6 with the HLB va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com