Movable and liftable unloading trolley

A technology of trolley and car body, applied in the field of movable lifting unloading trolley, which can solve the problems of prolonging the logistics link time, increasing labor costs, and reducing work efficiency, so as to reduce the links of manual handling and loading and unloading, reduce labor costs, and improve work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

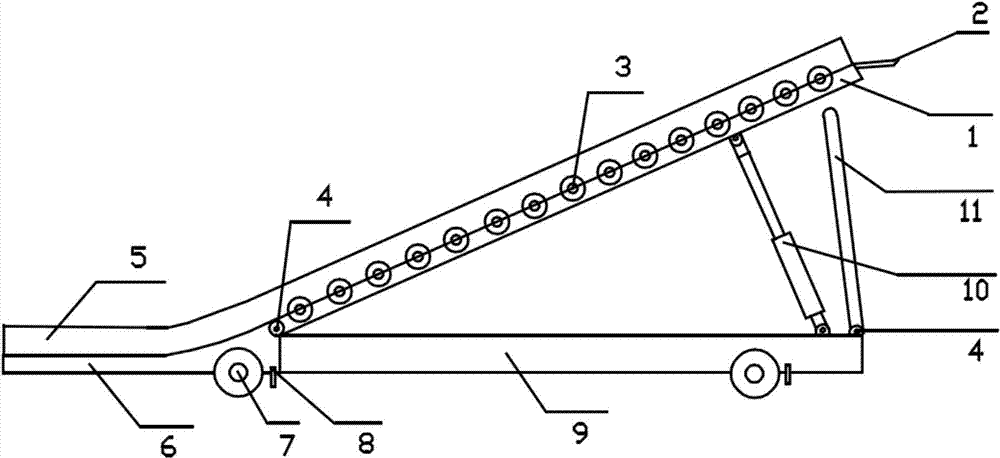

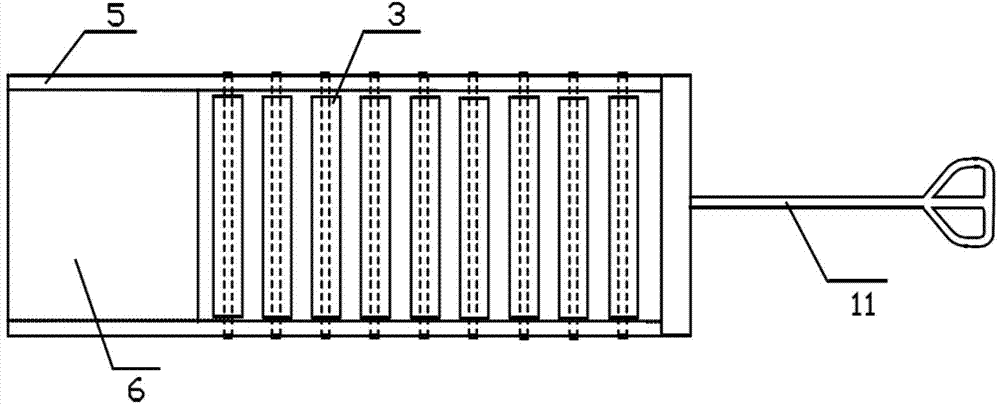

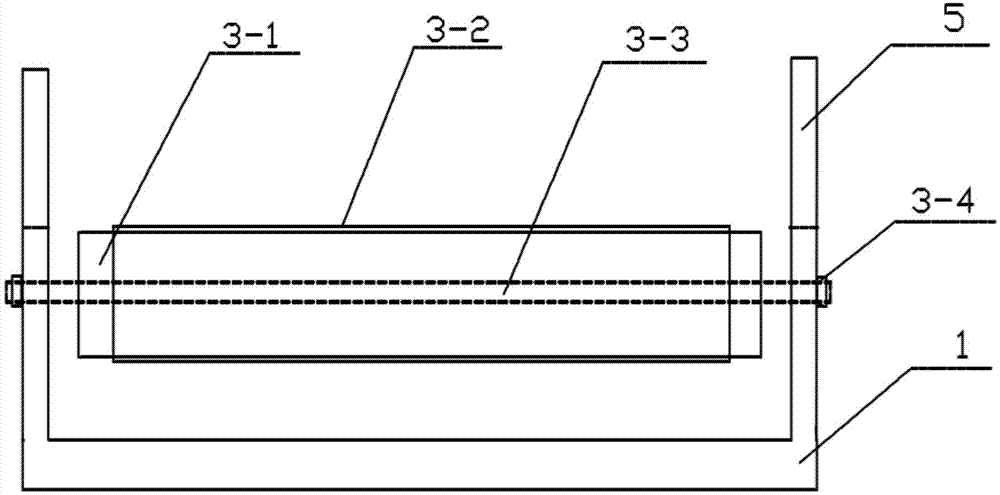

[0018] like figure 1 — Figure 5 As shown, the mobile lifting unloading trolley of the present invention includes a track 1, a lap plate 2, a roller 3, a hinged part 4, a guard plate 5, a buffer platform 6, a wheel 7, a wheel lock 8, a vehicle body 9, and a telescopic rod 10 and pull the handle 11. Its structure and connection mode are: the rear part of the body 9 is connected to the pull handle 11 through the hinge part 4, the front and rear wheels 7 are installed under the body 9, the track 1 is installed above the body 9, and its front end and the body 9 are hinged through the hinge part 4. The bottom of the other end is hinged with the telescopic rod 10, and a lap plate 2 is fixed at the end, the other end of the telescopic rod 10 is hinged with the vehicle body 9 through the hinge part 4, and several parallel rollers 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com