Telescopic belt conveyor changeable in amplitude and direction

A belt conveyor and telescopic technology, which is applied in the field of telescopic belt conveyors, can solve problems such as unsatisfactory one-time loading and unloading, and changes in height and direction, so as to reduce manual auxiliary handling, shorten working time, and increase the conveying range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

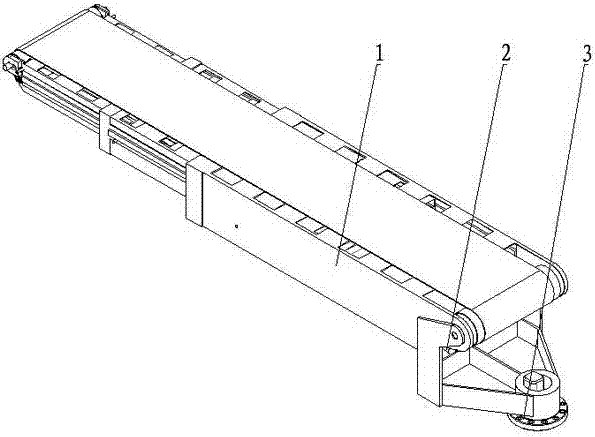

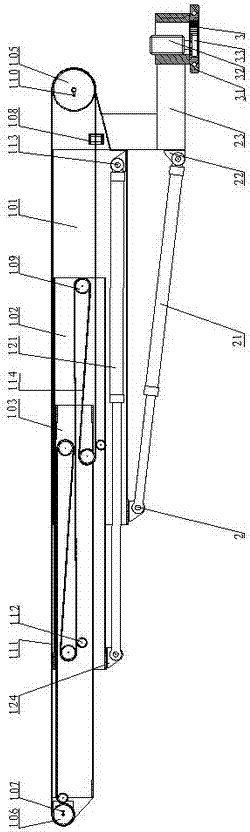

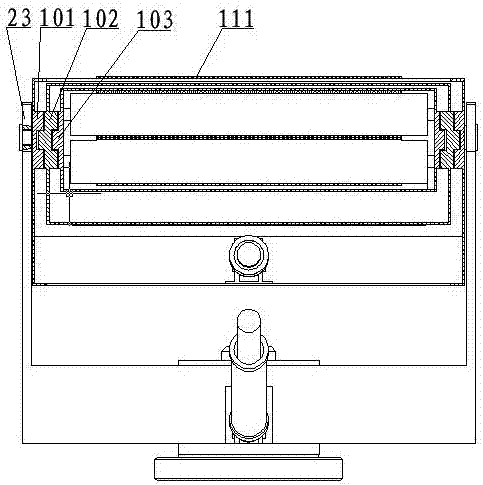

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention is composed of a three-section two-stage telescopic belt conveyor 1 with a telescopic function, a luffing mechanism 2 with a function of tilting and amplifying, and a swinging mechanism 3 with a function of swinging and steering.

[0017] The belt conveyor 1 consists of an outer frame 101, an intermediate frame 102, an inner frame 103, a driving drum 105, a reversing drum 106, a deflection adjustment device 107, a retaining pulley 108, a storage pulley 109, a tensioning Device 110, conveyor belt 111, idler roller 112, telescopic mechanism 113, belt storage mechanism 114 and so on. The belt conveyor 1 is a three-section two-stage telescopic belt conveyor.

[0018] The frame of the belt conveyor 1 adopts a telescopic structure. The outer frame 101, the middle frame 102, and the inner frame 103 are all thin-walled frame structures. The front and rear heights of the middle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com