Turnover device for automatic feeding and discharging of heating furnace, and implementation method thereof

A heating furnace, feeding and discharging technology, applied in the field of magnetic materials, can solve the problems of hidden safety hazards in manual operation, high product supporting temperature, high labor intensity, etc., and achieve the effect of reducing labor intensity, reducing turnover times, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

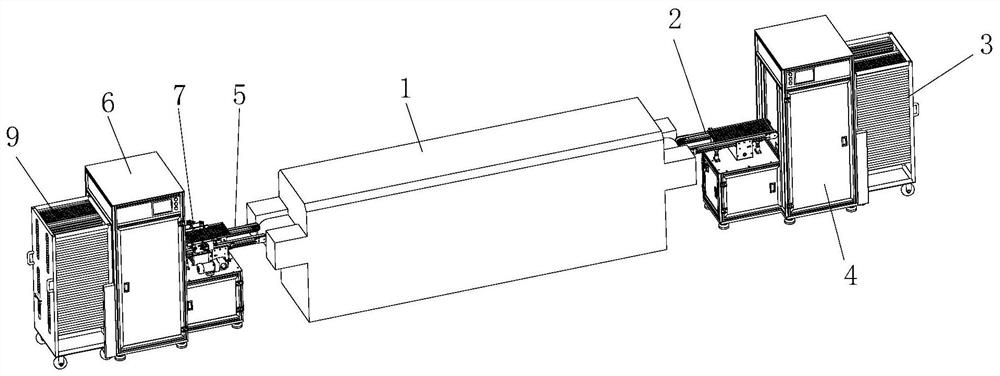

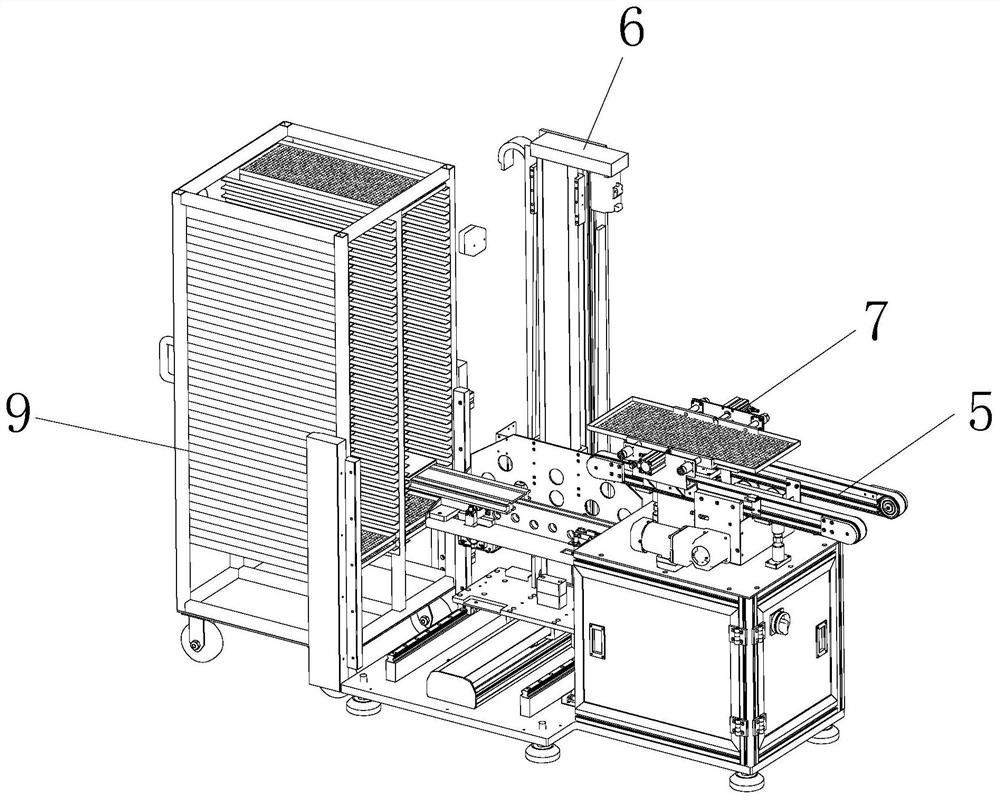

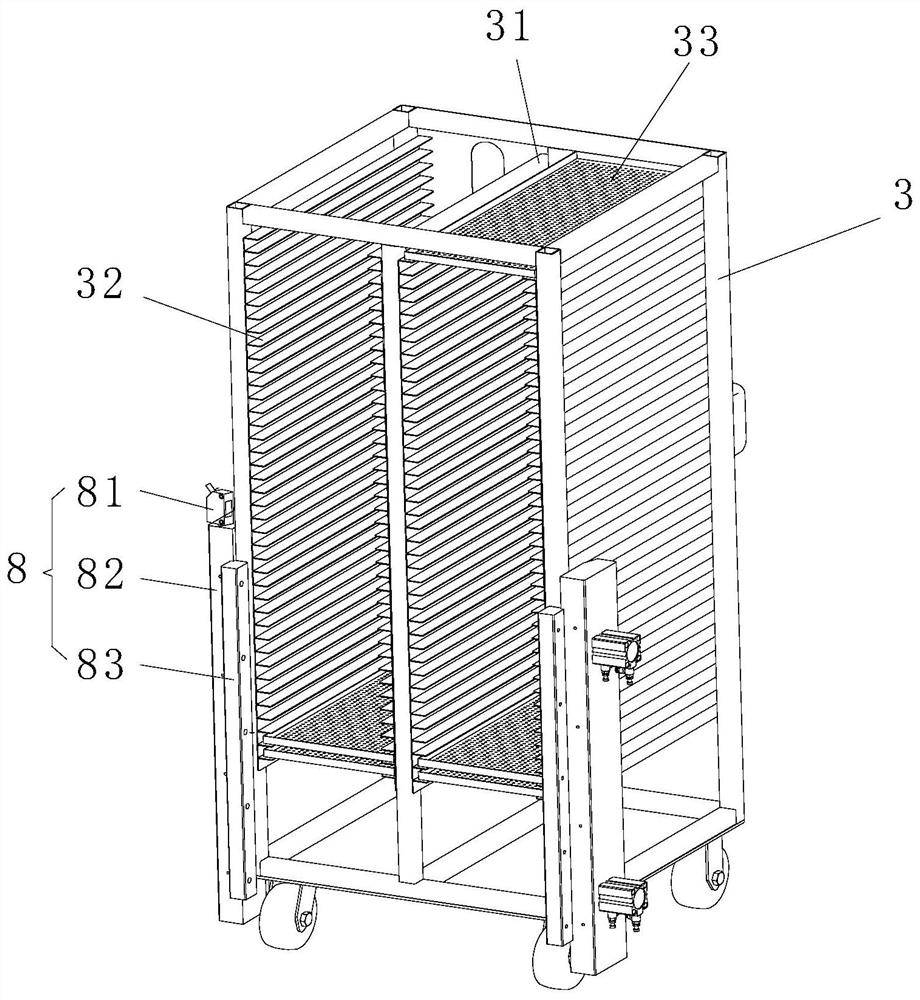

[0042] see Figure 1-7 , the present invention provides the following technical solutions: a turnover device for automatically feeding and discharging materials in a heating furnace, comprising a heating furnace body 1, the feeding end of the heating furnace body 1 is provided with a feeding conveyor belt 2, and the feeding conveyor belt 2 is far away from the heating furnace body 1 is provided with a feeding mechanism 4, and the side of the feeding mechanism 4 away from the feeding conveyor belt 2 is provided with a feeding turnover trolley 3, and the discharging end of the heating furnace body 1 is provided with a discharging conveyor belt 5, and the discharging The top of the conveyor belt 5 is provided with a retrieving positioning mechanism 7, the side of the discharge conveyor belt 5 away from the heating furnace body 1 is provided with a retrieving mechanism 6, and the side of the reclaiming mechanism 6 away from the discharge conveyor belt 5 is provided with a discharge...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 lies in: further, a position detection sensor 71 is provided on the discharge conveyor belt 5, and the position detection sensor 71 is connected to the controller signal.

[0054] By adopting the above technical solution, the product holder 33 on the discharge conveyor belt 5 is detected by the position detection sensor 71 .

[0055] Both the feed conveyor belt 2 and the discharge conveyor belt 5 are connected to the controller signal. In this embodiment, the feed conveyor belt 2 and the discharge conveyor belt 5 are both GVTWAS-140-800-25-TA220-SCM- sold by MISUMI. 15-H-C type conveyor belt; the position detection sensor 71 is E3Z-D61 sensor of Omron; the controller is FX3U-80MT / ES sold by Mitsubishi.

[0056] Further, the material taking positioning mechanism 7 includes a movable positioning mechanism, and the movable positioning mechanism is arranged on both sides of the discharge conveyor belt 5. The movable po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com