ECC non-dismantling formwork, concrete beam based on formwork and construction method thereof

A technology that does not need to dismantle formwork and concrete beams is applied in the directions of joists, girders, trusses, etc. It can solve the problems of inconvenient transportation and installation, difficult to guarantee integrity, weak fire resistance, etc., saving steel and forest resources, beneficial to The effect of environmental protection and saving engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

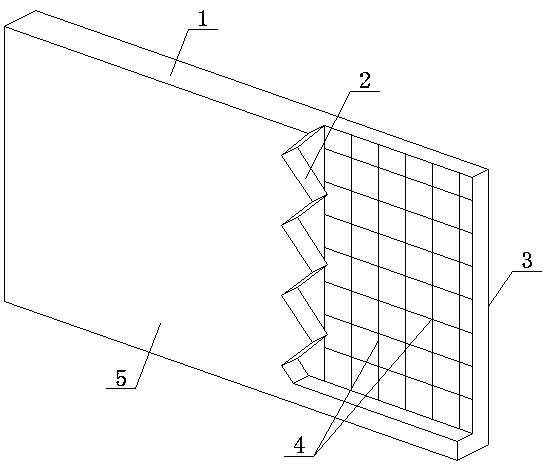

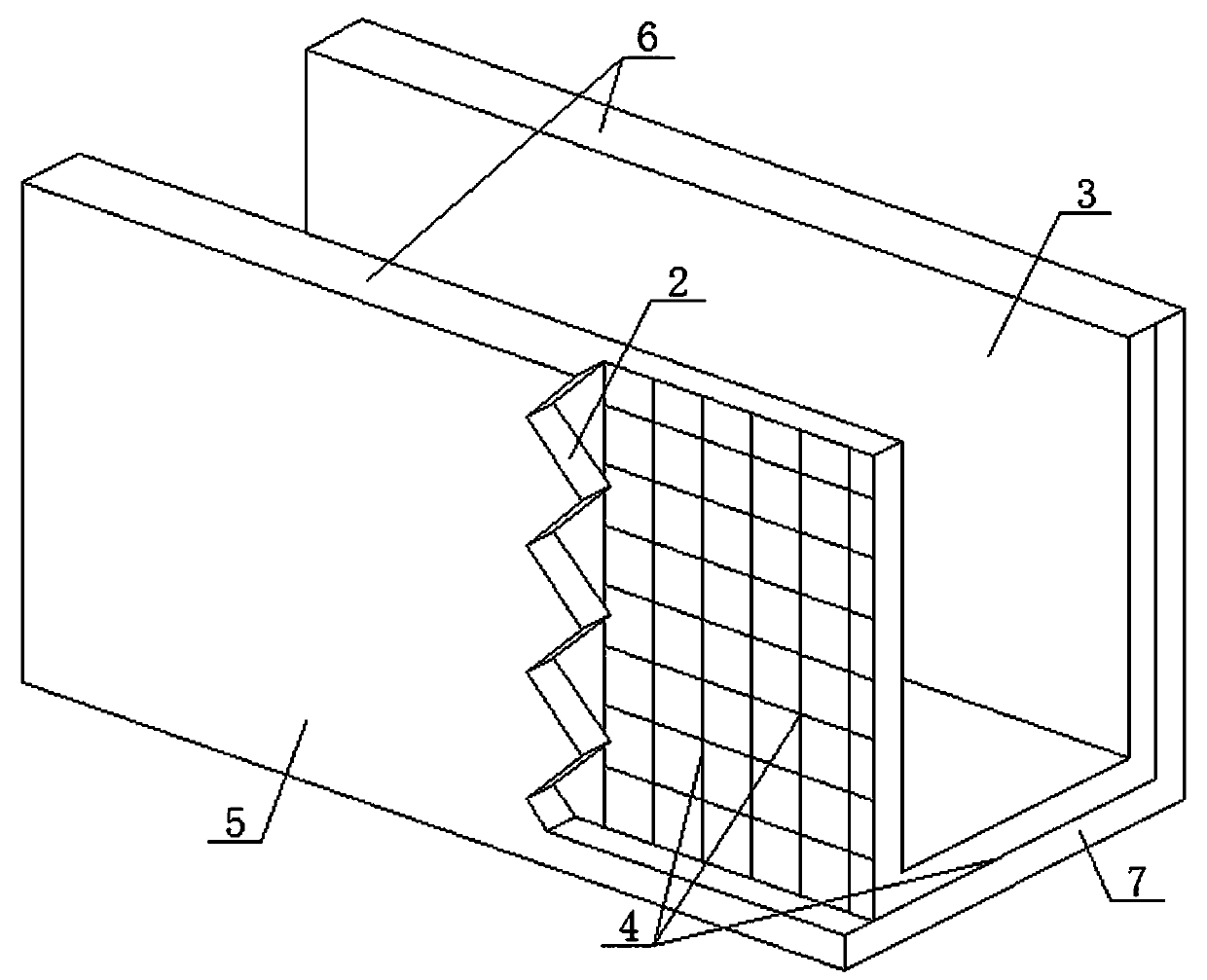

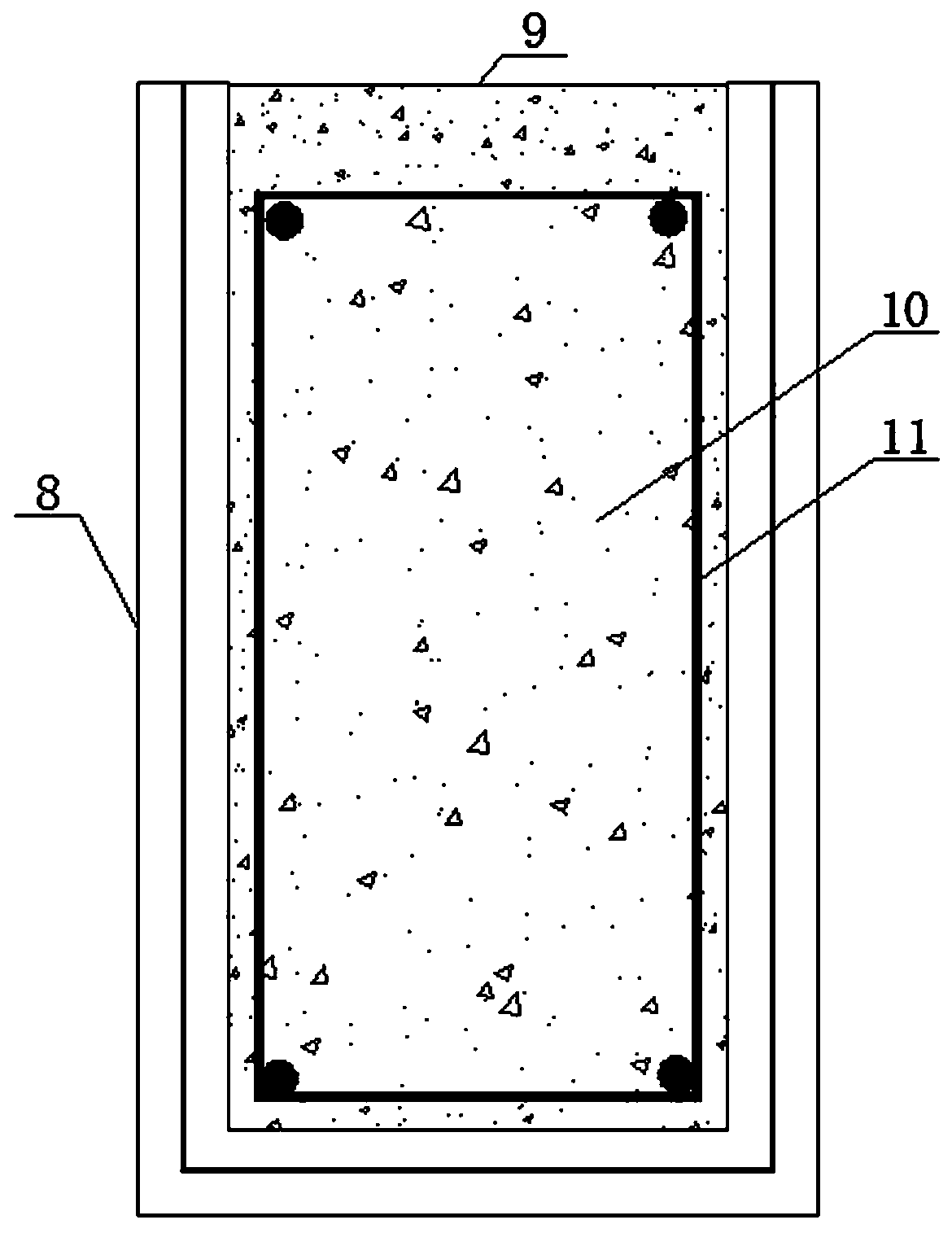

[0036] Such as figure 1 and figure 2 As shown, an ECC dismantling-free formwork includes a formwork body 1, and a built-in reinforcement layer 4 is provided in the formwork body 1. The formwork body 1 is made of cement-based composite material, and the outer surface 5 of the formwork body 1 is a smooth surface. , the inner side 3 of the template body 1 is a smooth surface, rough surface, concave-convex surface or sandblasting surface, and the built-in reinforcement layer 4 is a steel strand grid, fiber grid, FRP grid, uniformly distributed FRP bars or uniformly distributed steel bars; The formwork body 1 is U-shaped, that is, it includes a bottom plate 7 and side plates 6 vertically connected to both sides of the bottom plate 7 integrally.

[0037] As a preferred solution, the thickness of the bottom plate 7 is not less than 1 / 25 of the height of the beam body to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com