Process for washing sesame with water

A processing technology and sesame technology, which is applied in the field of sesame cleaning and production technology, can solve the problems of inability to sesame color, screening and subdivision of skin and kernel, etc., and achieve the effects of smooth cleaning and processing process, ensuring physical and mental health, and prolonging soaking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

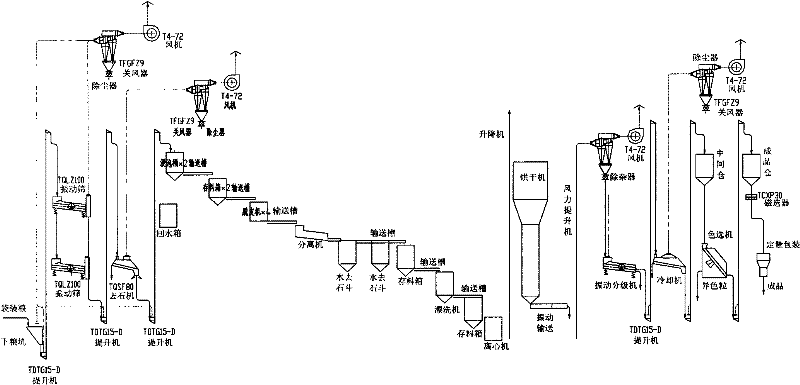

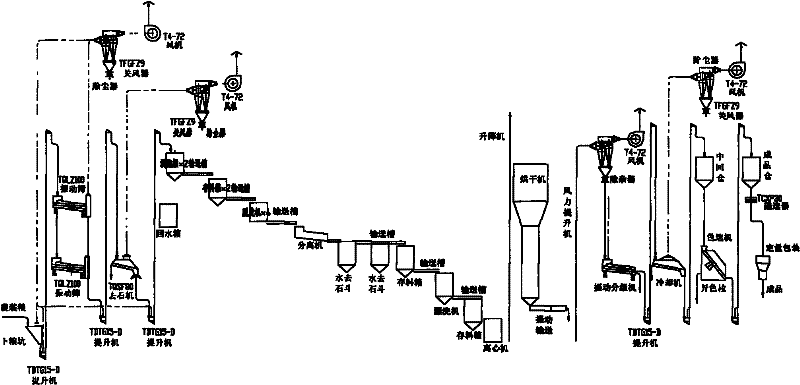

Image

Examples

Embodiment 1

[0017] A washing sesame processing technology, comprising the following steps:

[0018] 1. After the sesame is put into the grain pit to remove light impurities, it is sent to two juxtaposed vibrating sieves through the elevator to vibrate to remove large, medium, small and light impurities, and then sent to the destoner to remove the mud of the same size as the sesame. stone;

[0019] 2. Put the de-stoned and impurity-removed sesame seeds into the soaking barrel, soak them in 1% alkaline water at 60°C for 2.5 hours, send them to the peeling machine for peeling, and then put the skin kernels and sesame seeds into the separator for spraying Separate the sesame skin and sesame kernels, send the separated sesame kernels into two side-by-side water destoners to remove mud and stones of the same size as the sesame kernels, put them into the storage box for buffering, and then put the buffered sesame kernels into the In the rinsing machine, the sesame skin and kernels are further s...

Embodiment 2

[0023] A washing sesame processing technology, comprising the following steps:

[0024] 1. After the sesame is put into the grain pit to remove light impurities, it is sent to two juxtaposed vibrating sieves through the elevator to vibrate to remove large, medium, small and light impurities, and then sent to the destoner to remove the mud of the same size as the sesame. stone;

[0025] 2. Put the de-impured and stone-removed sesame seeds into the soaking barrel, soak them in 4% alkaline water at 55°C for 2 hours, send them to the peeling machine for peeling, and then put the skin kernels and sesame seeds into the separator for spraying Separate the sesame skin and sesame kernels, send the separated sesame kernels into two side-by-side water destoners to remove mud and stones of the same size as the sesame kernels, put them into the storage box for buffering, and then put the buffered sesame kernels into the In the rinsing machine, the sesame skin and kernels are further separ...

Embodiment 3

[0029] A washing sesame processing technology, comprising the following steps:

[0030] 1. After the sesame is put into the grain pit to remove light impurities, it is sent to two juxtaposed vibrating sieves through the elevator to vibrate to remove large, medium, small and light impurities, and then sent to the destoner to remove the mud of the same size as the sesame. stone;

[0031] 2. Put the de-stoned and impurity-removed sesame seeds into the soaking barrel and soak them in 5% alkaline water at 50°C for 1.5 hours, then send them to the peeling machine for peeling, and then put the skin kernels and sesame seeds into the separator for spraying Separate the sesame skin and sesame kernels, send the separated sesame kernels into two side-by-side water destoners to remove mud and stones of the same size as the sesame kernels, put them into the storage box for buffering, and then put the buffered sesame kernels into the In the rinsing machine, the sesame skin and kernels are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com