Double-lathe-head full-automatic numerically-controlled lathe

A CNC lathe, double head technology, applied in the direction of automatic lathes/semi-automatic lathes, turning equipment, turning equipment, etc., can solve the problems that affect the cutting accuracy of products, complex structure, low work efficiency, etc., and achieve the number of times of manual loading and unloading and turnover The effect of reducing, simplifying the processing process, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

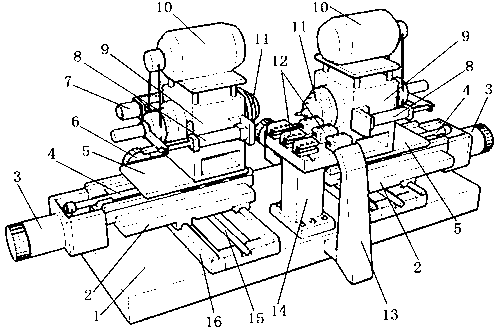

[0012] Such as figure 1 As shown, 1. Body, 2. X-direction moving carriage, 3. Z-direction motor, 4. Z-direction screw, 5. Z-direction moving carriage, 6. X-direction motor, 7. Encoder, 8. Loading and unloading cylinder, 9. Machine head base, 10. Drive motor, 11. Work chuck, 12. Tool holder, 13. Automatic discharge channel, 14. Tool holder, 15. X-direction screw, 16. Guide rail.

[0013] Double-head automatic CNC lathe, such as figure 1 As shown, it belongs to a kind of mechanical equipment for workpiece cutting and processing, and its structure is mainly composed of body 1, machine head, guide rail 16, X-direction moving carriage 2, Z-direction moving carriage 5 and tool holder 14, etc. .

[0014] The fuselage 1 is fixedly placed on the ground, mainly as the installation basis of other parts of the lathe; the guide rail 16 is provided with two, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com