Preparation process of polyurethane foam joint mixture

A technology of polyurethane foam and foam sealant, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., which can solve the problems of unqualified foam sealant production, incomplete fusion of polyurethane prepolymer, manual loading and unloading and vibration process cumbersome and other issues to achieve the effect of improving production efficiency and reducing cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

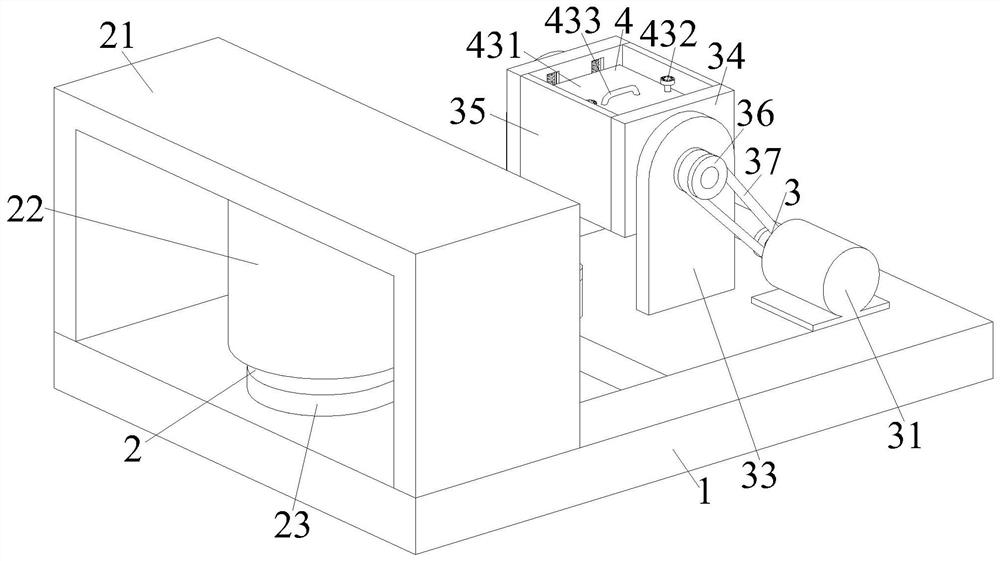

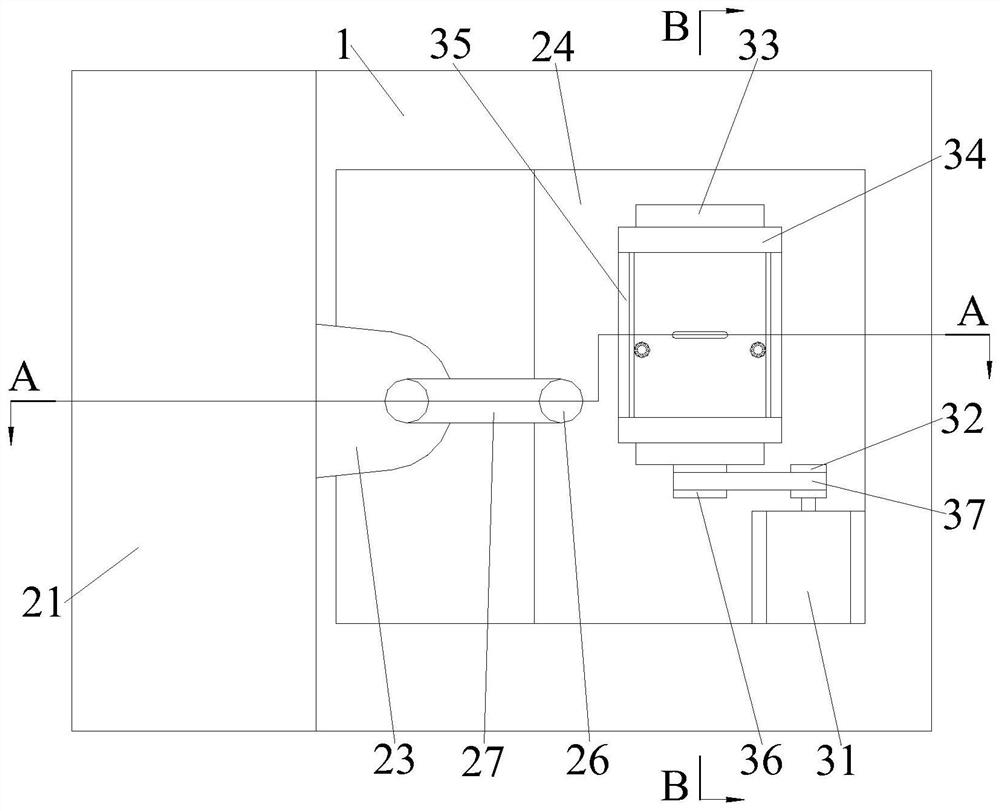

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

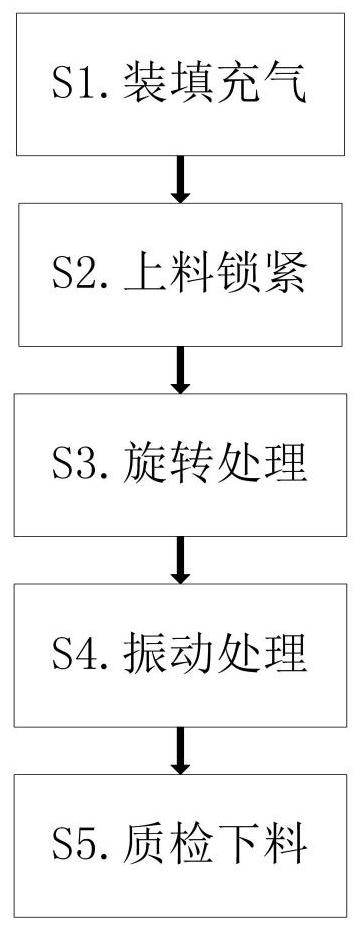

[0038] A preparation process of polyurethane foam caulking agent, the specific preparation process is as follows:

[0039] S1. Filling and filling: fill the tank with white material and black material in sequence, and install a valve to inflate;

[0040] S2. Loading and locking: After filling and filling the air, manually place the filled foam sealant on the clamping device 4, so that the clamping device 4 clamps and fixes it;

[0041] S3. Rotation processing: After the foam sealant is loaded and locked, the foam sealant is driven to rotate through the rotating device 3, so that the filled black material and white material are fused;

[0042] S4. Vibration treatment: during the rotation fusion process, the vibration device 2 drives the rotation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com