Small-sized moveable grain storing and drying barn

A mobile, drying warehouse technology, used in drying, dryers, heating devices, etc., can solve problems such as inconvenience, high energy consumption, and increased costs, and achieve the effects of improving quality, reducing environmental pollution, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

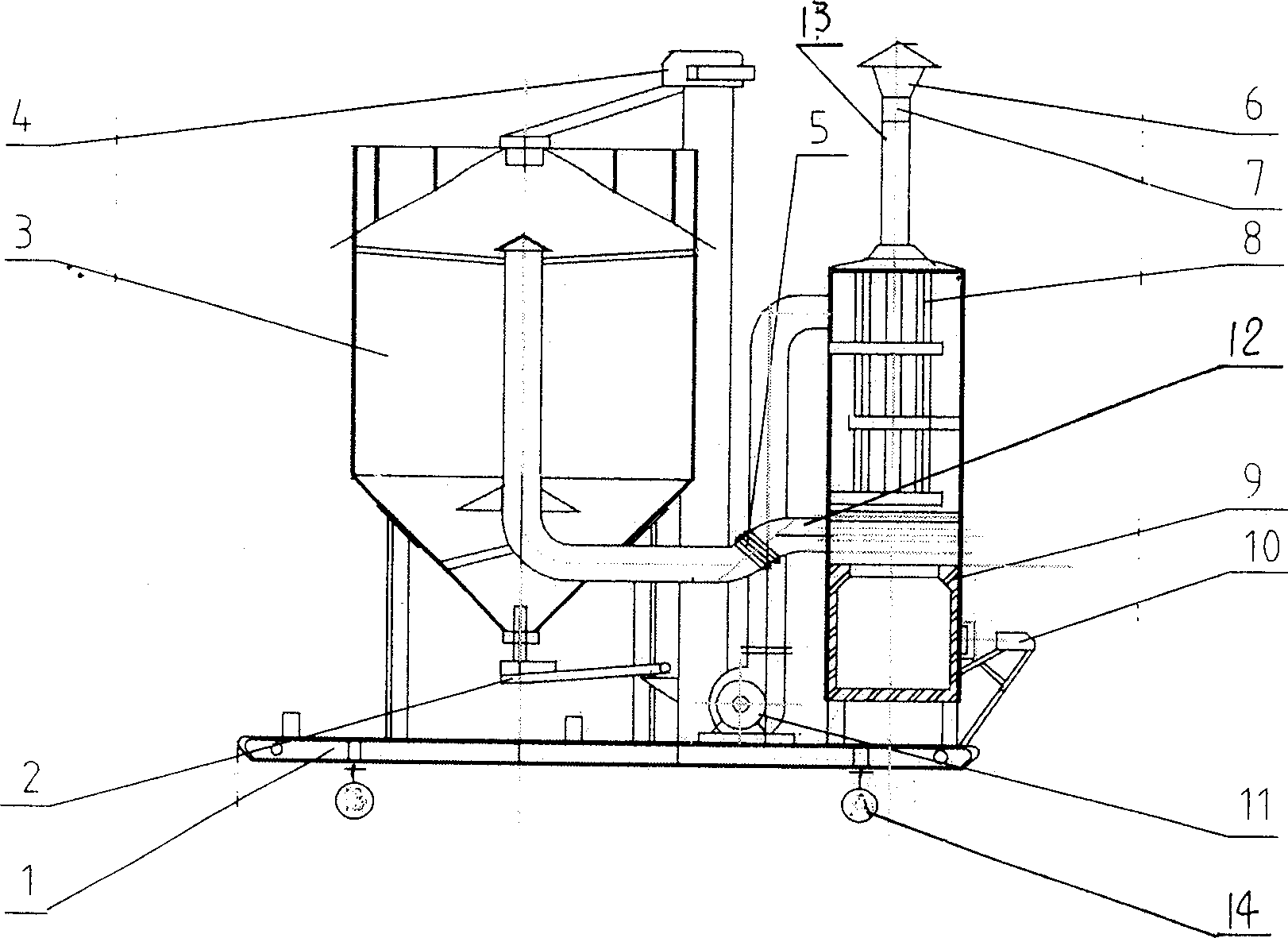

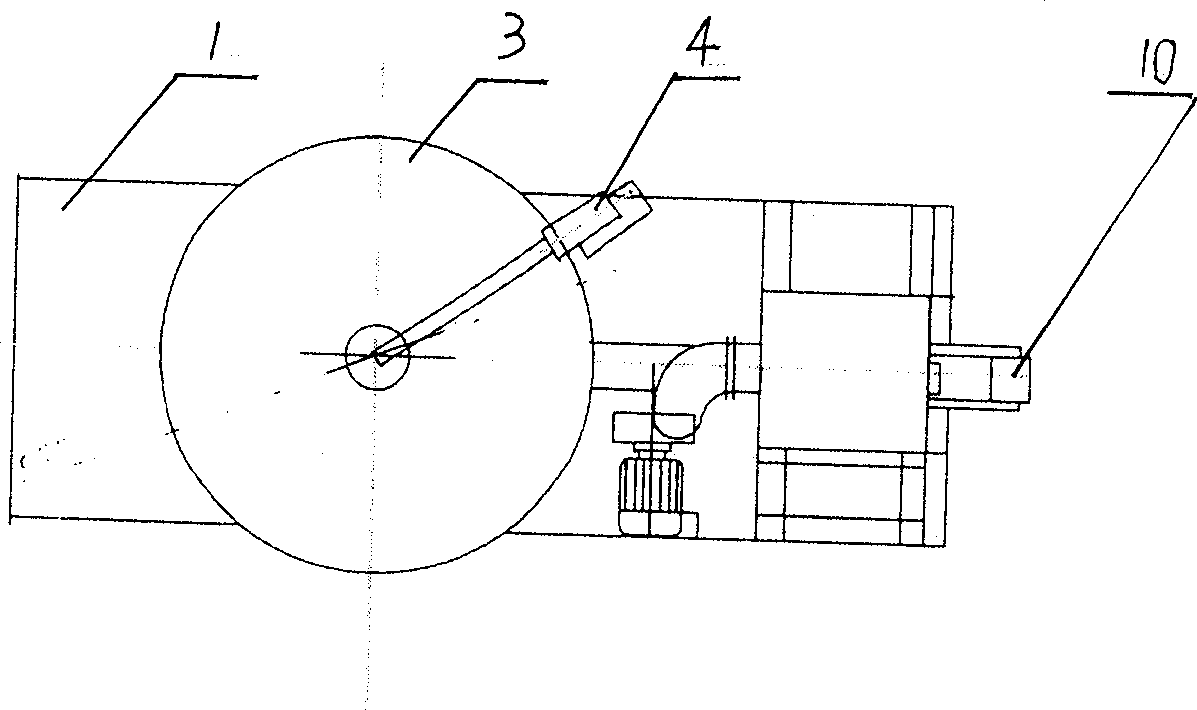

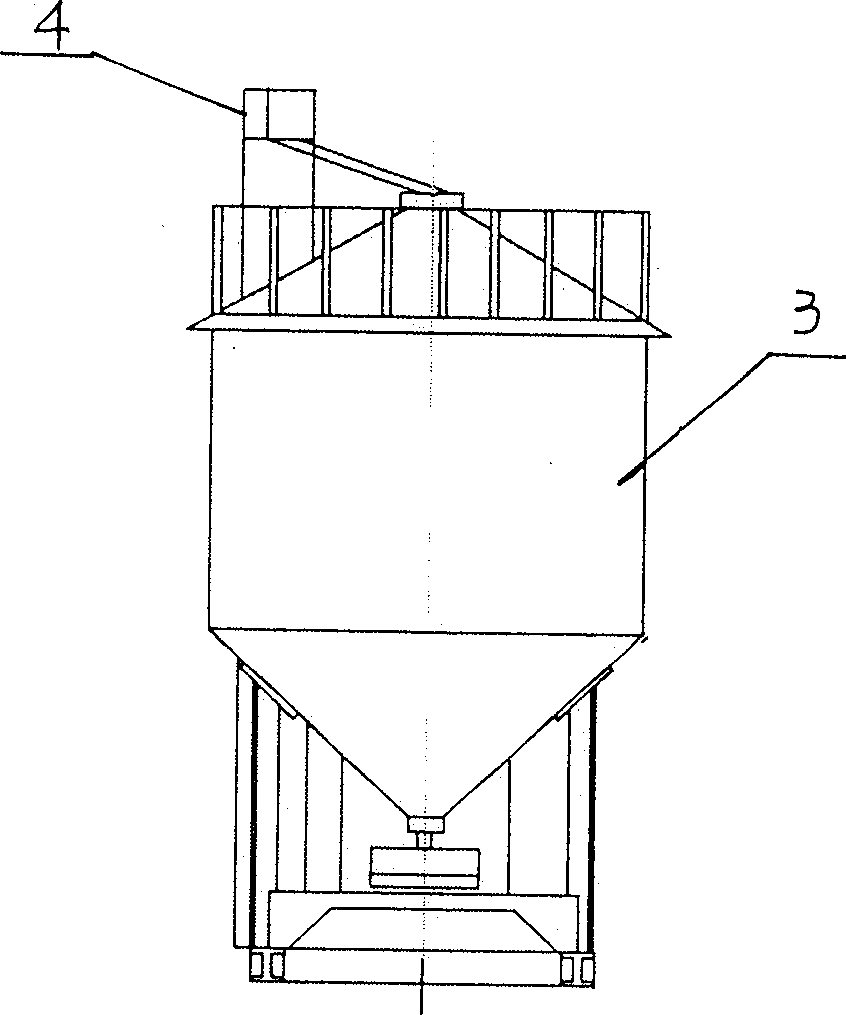

[0014] combine Figure 1-3 , the composition of the small mobile grain storage drying warehouse includes a ventilation drying warehouse 3 and a hot blast stove. One side of the drying bin is provided with a grain hoist 4 that circulates the grain between the lower outlet and the upper inlet of the ventilated drying bin. The lower part of the hot blast stove is a straw burning furnace 9, and the upper part is a heat exchanger 8. The hot air of the heat exchanger The outlet is connected to the ventilating and drying bin through the hot air duct 12. The hot blast duct between the ventilating and drying bin and the hot blast stove has a corrugated compensator 5, and the top of the heat exchanger is connected to the flue 13 with the induced draft fan 6. The flue is provided with The fire extinguishing cover 7 and the air blower 11 are connected with the top of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com