Encapsulating and matching machine of lead-acid storage battery plate

A technology of lead-acid battery and assembly machine, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of complexity, high failure rate, low efficiency, etc., and reduce the equipment failure rate , reduce pollution, improve production efficiency and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the drawings.

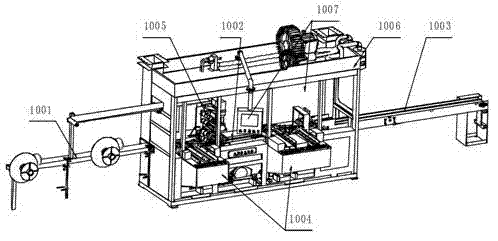

[0039] figure 1 It is a schematic diagram of the overall structure of the lead-acid battery plate encapsulation and assembly machine of the present invention, including a double-row paper feeding device 1001 and a plate conveying device 1002 connected in series. The plate conveying device 1002 is vertically arranged directly above the paper cutting device Device 1005, plate feeding device 1004 arranged perpendicular to the plate conveying device 1002, plate receiving device 1003 and electrical control system 1007 connected to the end of the plate conveying device 1002, and the complete machine frame 1006; wherein the paper feeding device 1001, the plate The conveying device 1002 and the board feeding device 1004 are key components of the present invention to overcome the defects of the prior art, and each component is usually installed on the frame 1006.

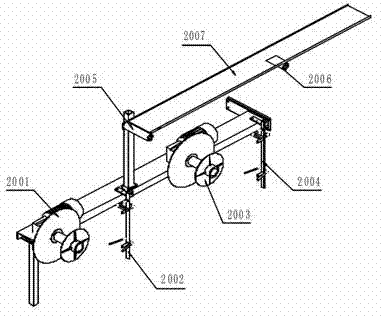

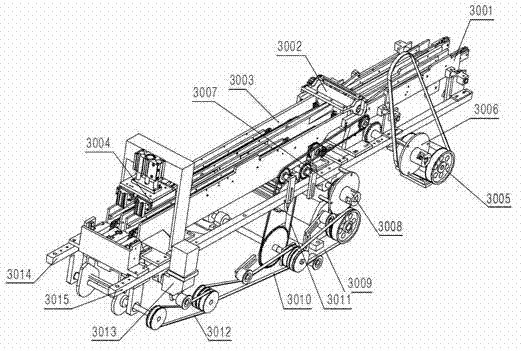

[0040] Combine figure 1 , fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com