Waste processor for smashing organic substances such as bone

A technology of garbage disposal and organic matter, which is applied in construction, water supply installations, and indoor sanitary piping installations, etc., can solve the problems of flying mosquitoes and flies, polluting people's living environment and quality of life, and smelly odor, etc., to reduce the follow-up The effect of processing, reducing waste handling, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

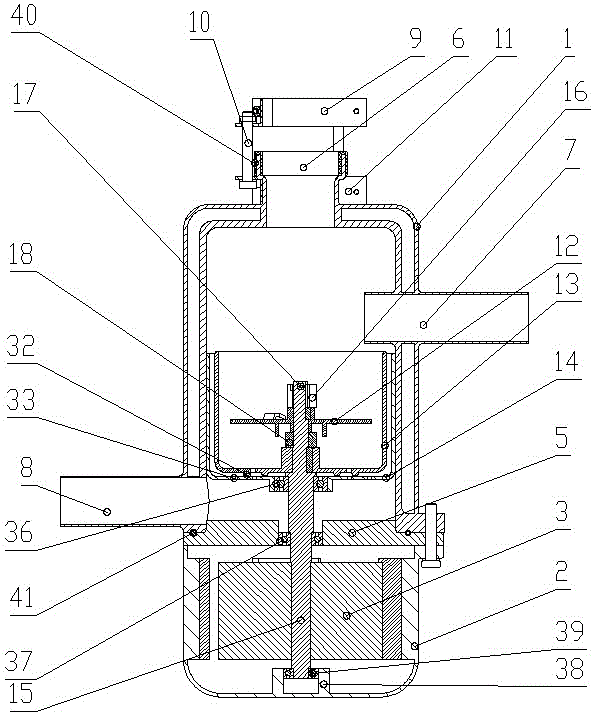

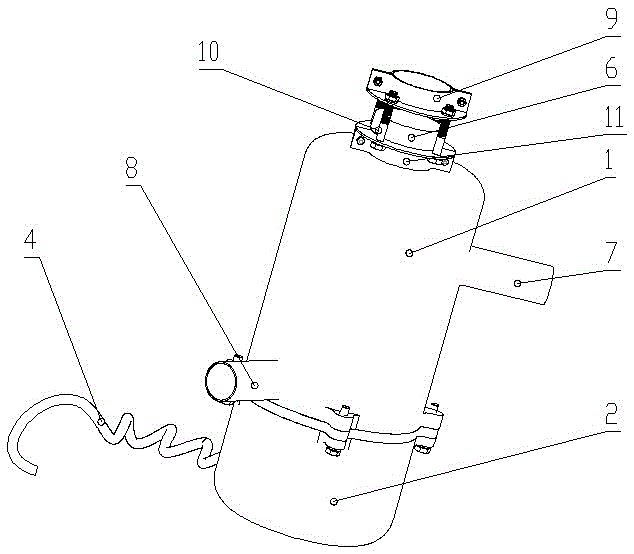

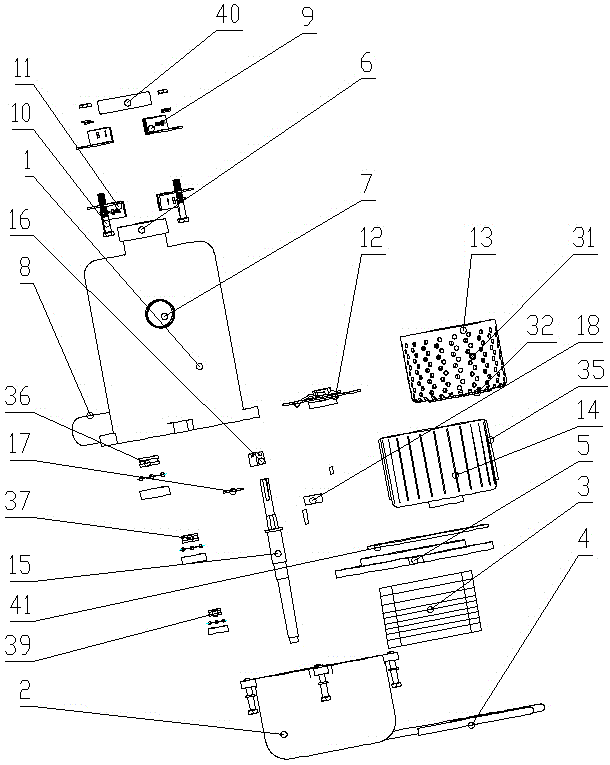

[0027] Such as Figure 1-Figure 7 As shown, a garbage disposer for crushing organic substances such as bones of the present invention includes an upper casing 1 and a lower casing 2, both of which are cylindrical in shape, and the lower end of the upper casing 1 is open. The upper end of the lower housing 2 is open, the lower end of the upper housing 1 is flange-connected with the upper end of the lower housing 2, the lower housing 2 is provided with a driving motor 3, and the lower part of the lower housing 2 leads outwards to connect with the driving motor 3 The power cord 4, the middle partition 5 is set between the upper shell 1 and the lower shell 2, the upper shell 1 is equipped with a crushing and grinding mechanism, the top of the upper shell 1 is provided with a water inlet pipe joint 6, and the upper shell 1 The side part is respectively provided with a feed pipe joint 7 and a discharge pipe joint 8, the feed pipe joint 7 is located above the crushing and grinding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com