Assembly device for plastic pipe clamp

A technology for assembling devices and pipe clamps, which is applied to household components, household appliances, and other household appliances to achieve the effects of saving costs, improving consistency, and reducing turnover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific implementation examples

[0011] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

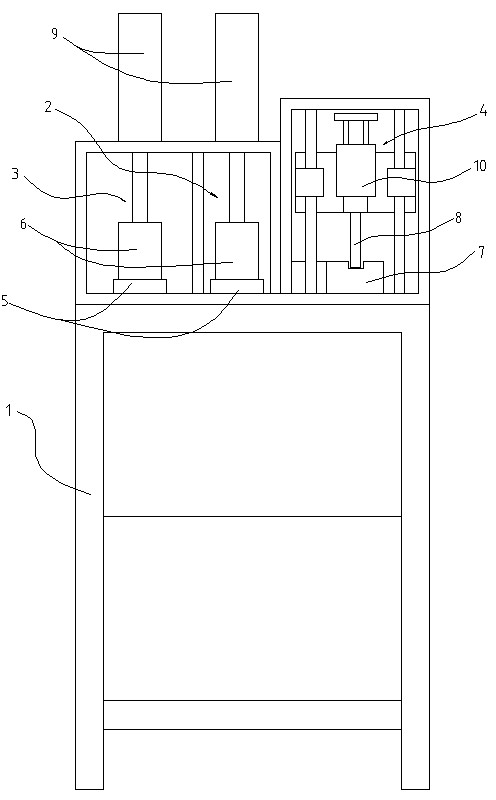

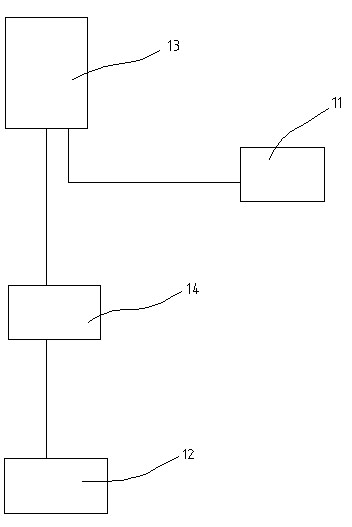

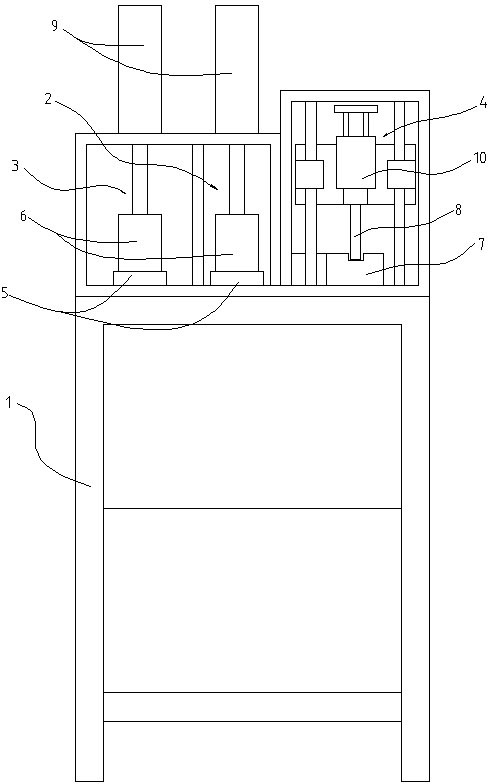

[0012] Such as figure 1 , figure 2 As shown, a kind of plastic pipe clamp assembly device of the present invention has frame 1, and on frame 1, is provided with nut adornment frock 2, adornment pin subfrock 3 and adornment bolt frock 4, adorns nut frock 2 and adorns pin The tooling 3 is composed of a bottom die 5 and a punching die 6, and the bolting tooling 4 is composed of a positioning die 7 and a rotary die 8. The punching die 6 is terminated with an air cylinder 9, and the rotary die 8 is terminated with an air motor 10. The cylinder 9 and the air motor 10 are provided with Electromagnetic valve 12, bottom mold 5 and positioning mold 7 are respectively provided with photoelectric sensor 11, and photoelectric sensor 11 is connected with PLC module 13, and electromagnetic valve 12 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com