Energy-saving chromate planar furnace

A chromate and planar technology, applied in the direction of progressive dryers, drying solid materials, dryers, etc., can solve the problems of single conveyor belt and low utilization rate of heat energy of equipment, so as to reduce bad quality and reduce the number of product turnover , the effect of reducing the potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

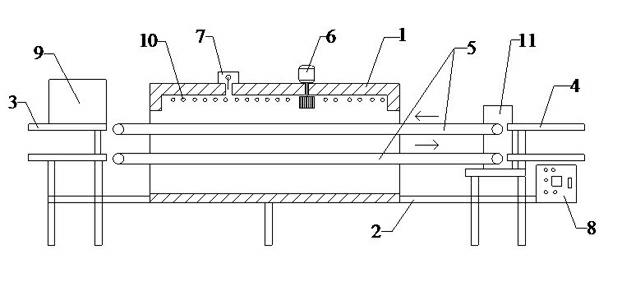

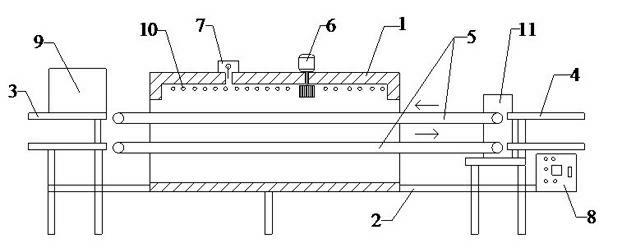

[0015] figure 1 It is a side view structural schematic diagram of a preferred embodiment of the energy-saving chromate flat furnace of the present invention.

[0016] refer to figure 1 , The energy-saving chromate flat surface furnace of the present invention mainly includes: a furnace body 1, a support 2, a placing plate 3 in the feeding area, a placing plate 4 in the unloading area, and a conveyor belt 5.

[0017] Such as figure 1 As shown in , the furnace body 1 is provided with a plurality of heating pipes 10 for drying sheet metal parts. It is fixed on the bracket 2. In addition, the conveyor belt 5 is divided into upper and lower groups, and their transmission directions are opposite. Group conveyor belts 5 are respectively docked.

[0018] In order to be able to drive two groups of conveyor belts 5, a power unit 11 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com