Preparation method of stainless steel coach plate for high-speed train

A technology for high-speed trains and stainless steel plates, applied in the field of metallurgy, can solve the problem of not inventing the strength level control method, etc., and achieve the effects of avoiding surface defects, high yield ratio and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

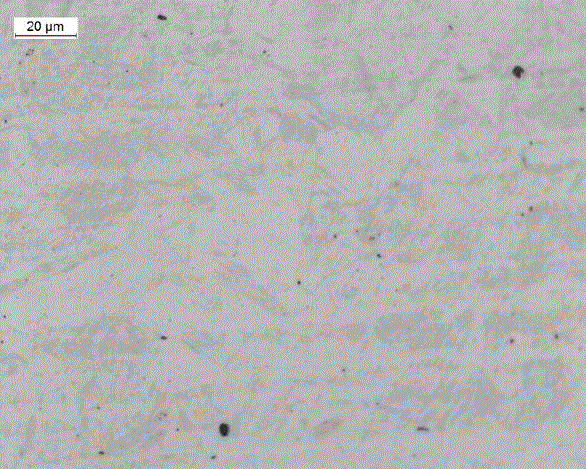

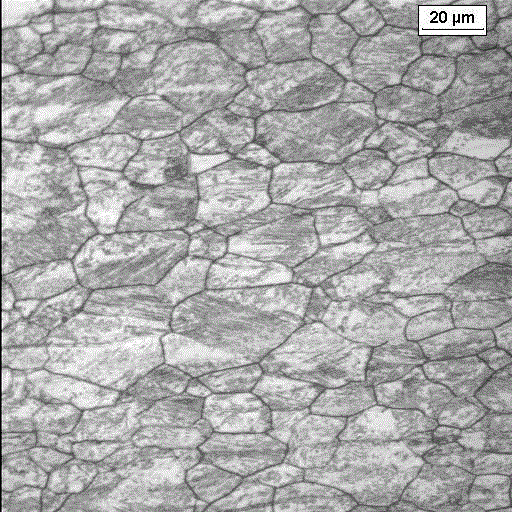

Image

Examples

Embodiment 1

[0026] Example 1 A 301L stainless steel slab whose components are C 0.024, N 0.112, Cr 17.06, Ni 7.01, Si 0.57, Mn 1.23, P 0.034, S 0.001, and the rest Fe is rolled at 1100°C, and finally rolled The temperature is 900°C, the coiling temperature is 610°C, and the hot-rolled sheet is rolled into a 6mm hot-rolled sheet; the hot-rolled sheet is kept at 1050°C for 10 minutes and then water-quenched, and the volume fraction is 20% to HNO 3 , HF with a volume fraction of 70% and H with a volume fraction of 10% 2 The acid solution of O is pickled at room temperature and rolled into a 1.8mm thick cold-rolled sheet at a reduction rate of 70% on a 4-roll cold rolling mill. Then, when the annealing temperature is 1100°C, the strength grade is LT Carriage board; when the annealing temperature is 950°C, the strength grade is DLT; when the annealing temperature is 890°C, the strength grade is ST; when the annealing temperature is 840°C, the strength grade is MT When the annealing temperatu...

Embodiment 2

[0028] Example 2 The components are C 0.024, N 0.112, Cr 17.06, Ni 7.01, Si 0.57, Mn 1.23, P 0.034, S 0.001, and the rest is Fe. The 301L stainless steel slab is rolled at 1100°C and finished rolling The temperature is 900°C, the coiling temperature is 610°C, and the hot-rolled sheet is rolled into a 6mm hot-rolled sheet. The hot-rolled sheet is kept at 1100°C for 20 minutes and then water-quenched. After the volume fraction is 20%, it is HNO 3 , HF with a volume fraction of 70% and H with a volume fraction of 10% 2 The acid solution of O was pickled at room temperature and then rolled on a 4-roll cold rolling mill at a reduction rate of 80% to form a cold-rolled sheet of 1.2 mm. Then, when the annealing temperature is 1050°C, a car body panel with a strength grade of LT is obtained; when the annealing temperature is 910°C, a car body plate with a strength grade of DLT is obtained; when the annealing temperature is 860°C, a car body with a strength grade of ST is obtained Wh...

Embodiment 3

[0030] Example 3 The 301L stainless steel slab whose composition is C 0.024, N 0.112, Cr 17.06, Ni 7.01, Si 0.57, Mn 1.23, P 0.034, S 0.001, and the rest is Fe is rolled at 1100°C, and the final rolling temperature is 900°C , the coiling temperature is 610°C, hot-rolled and rolled into a hot-rolled sheet of 6 mm; the hot-rolled sheet is kept at 1050°C for 30 minutes and then water-quenched; after the volume fraction is 20%, it is HNO 3 , HF with a volume fraction of 70% and H with a volume fraction of 10% 2 After pickling with acid solution of O at room temperature; on a 4-roll cold rolling mill, roll it into a 0.8mm cold-rolled sheet at a reduction rate of 88%; then when the annealing temperature is 1080°C, the strength grade is LT When the annealing temperature is 940°C, the strength grade is DLT; when the annealing temperature is 900°C, the strength grade is ST; when the annealing temperature is 830°C, the strength grade is MT car body plate; when the annealing temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com