Piezoelectric energy collection rectifier for open-circuit type optimization of turnover time

A technology of inversion time and piezoelectric energy, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, irreversible AC power input conversion to DC power output, electrical components and other directions, which can solve the problem of reducing switch on-time Rectifier extraction efficiency, limiting the output voltage amplitude of the piezoelectric terminal, increasing the conduction loss, etc., to achieve the effect of optimizing the switch conduction time, reducing power consumption, and increasing net energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

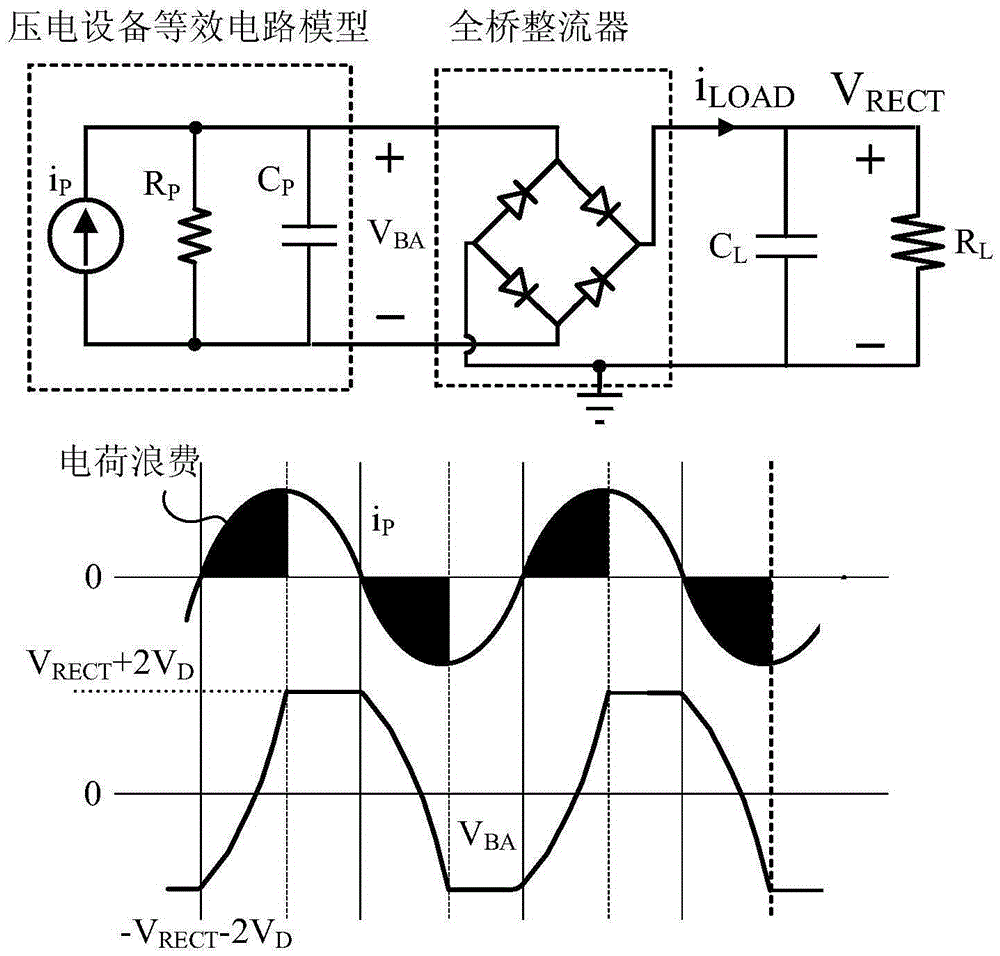

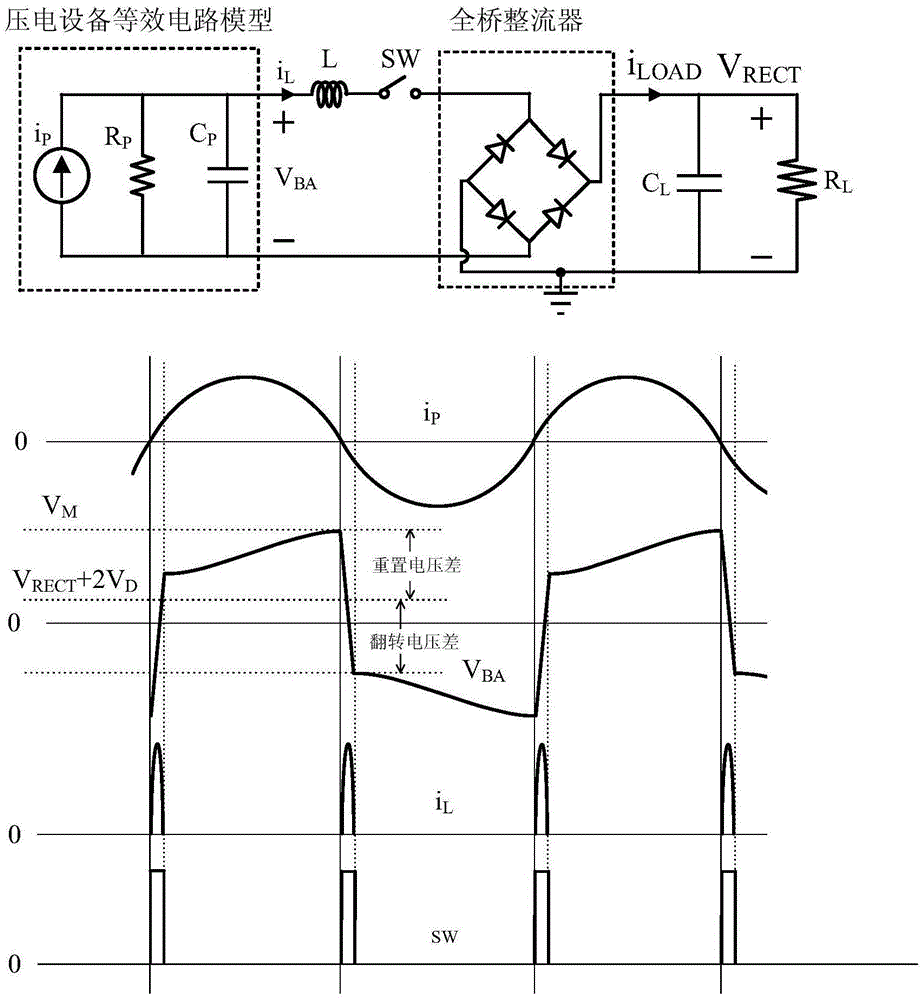

[0017] like figure 1 , figure 2 and image 3 As shown, the piezoelectric conductor is equivalent to a circuit model that includes a current source i in parallel P , a resistor R P and a capacitor C P . Suppose the current source can be expressed as

[0018] i P =I P sin(2πf P t)(1)

[0019] where the current amplitude I P It is related to the acceleration of the vibration source, f P Corresponding to the vibration frequency of the vibration source. In addition, because the resistor R P The value of is very large in megabytes, so it can be ignored in the analysis, and the load capacitance C is assumed L The value is large, making V RECT It can be regarded as a stable DC voltage.

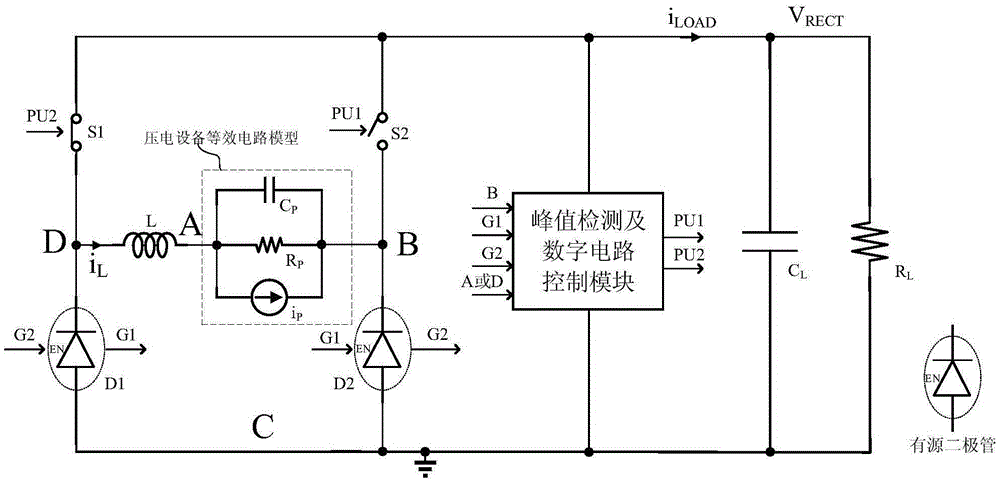

[0020] image 3 Shown is the rectifier of the present invention, its basic operation principle can refer to Figure 4 , before time t3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com